Benefits of Conveyor Metal Detectors in Food Safety & Quality Control | Samegram

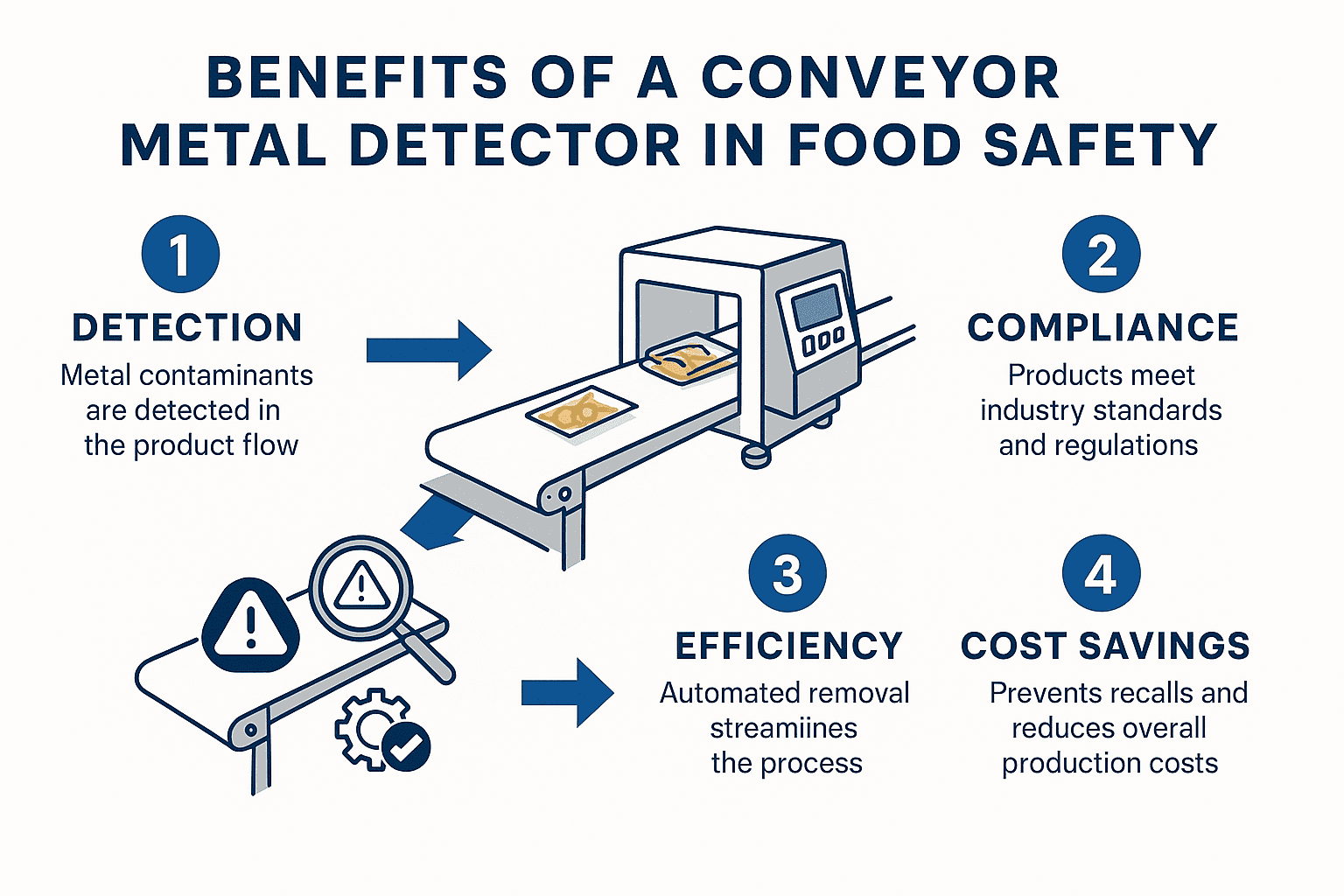

In today's fast-paced food industry, ensuring product purity and consumer safety is more critical than ever. Conveyor metal detectors play a pivotal role in this process, serving as an essential tool for identifying and removing unwanted metal contaminants from production lines. These systems, often referred to simply as metal detectors, help manufacturers maintain high standards of quality while complying with stringent regulations. At Samegram Machinery, we've been at the forefront of developing intelligent weighing and inspection solutions for over 20 years, delivering reliable conveyor metal detector systems that integrate seamlessly into food processing environments. Our expertise stems from serving industries like food, pharmaceuticals, and cosmetics across more than 60 countries, with over 5,000 units installed worldwide.

Whether you're dealing with packaged baked goods, dairy products, or ready-to-eat meals, incorporating a conveyor metal detector can prevent costly recalls, protect your brand reputation, and streamline operations. In this article, we'll explore the key advantages of these systems, drawing on practical insights to help you address real-world challenges in food safety and quality control.

Enhanced Detection Capabilities for Superior Contaminant Control

One of the primary benefits of conveyor metal detectors is their ability to accurately identify a wide range of metal contaminants, including ferrous, non-ferrous, and stainless steel particles. These impurities can enter the production stream from various sources, such as worn machinery parts, broken tools, or even raw material suppliers. Without proper detection, they pose serious risks to consumers, potentially causing injuries or health issues.

In food safety applications, conveyor metal detectors use advanced electromagnetic induction technology to scan products in real-time as they move along the belt. This ensures that even small metal fragments—down to sensitivities like 0.6mm for ferrous metals in our systems—are caught before packaging. For instance, our SCM-4530L2 Checkweigher with Metal Detector Combination System offers high-precision detection with adjustable sensitivity levels, allowing it to handle diverse product types without compromising accuracy.

This capability directly solves common problems like product contamination recalls. By integrating such a system early in your line—say, during raw material inspection or post-processing—you can minimize false positives through sophisticated signal processing that distinguishes between actual contaminants and product variations. At Samegram, our metal detectors feature multi-frequency technology that auto-adjusts to different product properties, reducing unnecessary alerts and keeping your line running smoothly. This not only boosts quality control but also gives you peace of mind, knowing your products meet global standards like HACCP and ISO22000.

Seamless Integration and Efficiency in Production Lines

Integrating a conveyor metal detector into your existing setup doesn't have to disrupt operations. These systems are designed for easy installation, often fitting compactly into tight spaces without requiring major overhauls. This modularity is especially useful in food processing, where production lines must handle high volumes efficiently.

Take our DD-500 Series Digital Conveyor Metal Detector, for example—it's built with a stainless steel frame that's IP65-rated for dust and water resistance, making it ideal for wet or harsh environments common in food facilities. With belt speeds up to 28m/min and the ability to store up to 100 product formulas, it adapts quickly to multiple SKUs, saving time during changeovers.

From an efficiency standpoint, these detectors automate what was once a manual, error-prone process. They trigger automatic rejection mechanisms, like push rods or sliding ejectors, to remove contaminated items without halting the entire line. This reduces downtime, prevents equipment damage from metal shards grinding into machinery, and ultimately lowers maintenance costs. In one of our client cases with a major East China food processor handling packaged baked goods, implementing our conveyor metal detector reduced false alarms by 85% and increased output by 18%. If you're facing bottlenecks in your quality checks, a system like this can transform your workflow, ensuring continuous operation while maintaining top-tier safety.

Ensuring Regulatory Compliance and Brand Protection

Compliance with food safety regulations isn't optional—it's a necessity for market access and consumer trust. Conveyor metal detectors help you achieve this by providing verifiable proof of contaminant-free products. Standards such as FDA guidelines, GMP, and BRC require robust foreign object detection, and failing to meet them can lead to hefty fines or shutdowns.

Our systems at Samegram are engineered to exceed these requirements, with features like real-time data logging and USB export for easy audits. The SCM-4530L2, for instance, combines metal detection with precise weighing (±0.3-1g accuracy), allowing you to monitor both contaminants and weight compliance in one pass. This dual functionality is perfect for pharmaceuticals or food items like potato chips and canned goods, where even minor deviations can trigger recalls.

By catching issues early, these detectors prevent contaminated products from reaching shelves, safeguarding your brand from negative publicity. We've seen clients avoid economic losses by integrating our detectors, which offer full traceability through MES/ERP connectivity. If regulatory audits are a pain point for your operation, investing in a conveyor metal detector can streamline compliance efforts, turning a potential liability into a competitive advantage.

Cost Savings and Long-Term Operational Reliability

Beyond immediate safety benefits, conveyor metal detectors deliver substantial cost savings over time. By preventing metal contaminants from damaging downstream equipment—like mixers or packaging machines—they extend machinery lifespan and cut repair bills. Early detection also minimizes product waste, as only affected items are rejected rather than entire batches.

At Samegram, our focus on durable, sustainable design means our systems are built to last. With 304 stainless steel construction and modular upgrades, they reduce energy consumption and support clean-in-place protocols, aligning with eco-friendly practices in food production. Our factory, spanning over 4,000 m² and certified under ISO9001 and CE standards, ensures every unit undergoes rigorous quality checks, including calibration and environmental simulations.

For businesses concerned about ROI, consider this: implementing a conveyor metal detector can pay for itself through avoided recalls and improved throughput. Our free sample testing service lets you verify performance on your products before purchase, ensuring a perfect fit. Plus, with lifetime technical support and a 12-month warranty, you get ongoing reliability without hidden costs.

Practical Tips for Implementing Conveyor Metal Detectors

To maximize these benefits, start by assessing your production line's pain points—where are contaminants most likely to enter? Position the detector at critical control points, such as after mixing or before final packaging. Regular calibration is key; our systems include auto-calibrating features to maintain accuracy in varying conditions.

Train your staff on the intuitive touchscreen interfaces to handle adjustments swiftly. And for optimal integration, opt for combination systems that pair metal detection with checkweighing, like our SCM-4530L2, which handles goods up to 2,000g with electromagnetic induction for precise results.

Why Choose Samegram for Your Metal Detector Needs

As a high-tech enterprise dedicated to intelligent automation, Samegram Machinery stands out with our commitment to innovation and customer-driven solutions. From our advanced R&D to in-house manufacturing with CNC precision, we deliver conveyor metal detectors that are not just tools but partners in your success. Whether you need a standalone unit or a fully customized system, our team offers pre-sales consultations, onsite demos, and global support to ensure seamless implementation.

Ready to elevate your food safety and quality control? Contact us today for a free consultation or sample test. Visit our website to explore our full range of metal detectors and see how we can tailor a solution for your line.

Hot-Sale Metal Detectors

HC-700 gravity fall metal separator offer precise,hygienic and sealed metal removal for food and pharma use.

DD-220 is a food conveyor metal detector designed for aluminum foil packaging,with high sensitivity and easy integration.

DD-360 Series is a food-grade metal detector conveyor system. Ideal for food industry and food production lines.

Customizable metal detector for conveyor belt with dual frequency, high sensitivity, and strong anti-interference.

DD-500 Series is an advanced conveyor belt metal detector using smart touch-screen control. Ideal for food production and other