Smart and Precision Linear Combination Weigher

Smart, high-precision system for fast, flexible, and accurate weight combination in semi-automatic packaging environments.Ideal for irregular, fragile products

- Introduce

- Products

- Featured Products

- Support

- Cases

- FAQ

- Blog

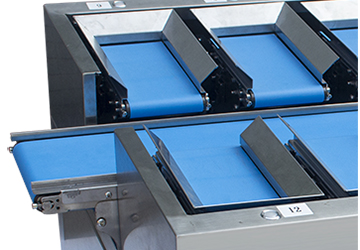

Intelligent Linear Combination Weigher

- Real-time optimal combination with smart weighing algorithm

- High-precision weighing with ±0.3g accuracy per head

- Modular multi-channel design for flexible configurations

- Food-grade stainless steel with basic waterproof protection

- Auto recipe switching for 20+ packaging formats

- Easy integration with ERP and MES systems

Exceptional Weighing Accuracy

Achieves precise target weights through intelligent combination logic, minimizing product giveaway and ensuring compliance with strict packaging standards.

High-Speed Operation for Increased Throughput

Supports rapid weighing and discharging cycles, enabling faster packaging speeds and boosting overall production efficiency.

Optimized for Diverse Product Types

Handles a wide range of materials—granules, snacks, nuts, frozen food—making it ideal as a food combination weigher or for mixed product applications.

Seamless Integration into Existing Lines

Easily connects with vertical or horizontal form-fill-seal machines and supports real-time data for any combination weigher packing line.

Combination Weigher Related Products

Provide the Combination weigher to Your Production Line

- Precision:combination weigher handles fruits, seafood, and hardware with ±0.1-3g accuracy, ensuring compliance.

- IP65-rated:multihead weigher with detachable belts simplifies cleaning, ideal for food combination weighing.

- Smart:combination weighing machine with ERP integration, real-time alerts, and multi-language support boosts efficiency.

Get free

Intelligent Weighing System Selection Guide

- Weight Inspection Recommendations for Different Situations

- Key Considerations Before Automation Upgrades

- Return on Investment Analysis for Weight Inspection Systems

Source factory

One-Stop Service Support

Customized solutions

Specialized multi-head combination weighing solutions crafted for complex batching and portioning needs.

Installation, commissioning, and diagnosis

Online support to adjust combination parameters and diagnose system performance efficiently.

Professional certification and technical support

Technical remote assistance ensuring precise combination logic and compliance with production targets.

Training and equipment maintenance

Web-based training covering combination weigher programming, troubleshooting, and upkeep.

Related Cases

- Industry:

- Fresh poultry processing

- Equipment:

- 12-head linear combination weigher

- Country:

- Selangor, Malaysia

faq

Frequently Asked Questions

- Q: Can SameGram systems integrate with MES or ERP systems and maintain audit records?SameGram systems integrate with MES/ERP and provide audit logs, traceability, and production records to support global food safety compliance.

- Q: What is a combination weigher and how does it work?Combining computer control with multiple scales, a combination weigher delivers rapid, precise target weights, minimizing giveaway across diverse packing lines.

- Q: What's the difference between linear combination weighers and multihead weighers?Linear combination weighers and multihead weighers both use combination weighing, but differ in structure, automation level, and application focus.

- Q: Is more heads always better in a combination weigher? What determines the number of heads?More heads in a combination weigher increase flexibility and speed, but the right number depends on the product and application.

- Q: How a combination weigher calculate combinations?A combination weigher uses real-time data to perform combination calculation weighing, selecting the best weight match from multiple heads.

- Q: How does SameGram customize solutions for different production lines and industries?SameGram customizes weighing and inspection systems to fit different industries and production lines, ensuring efficiency, compliance, and flexibility.

Linear Combination Weigher Knowledge Hub

Contact Us

Get solutions

Get free quotes

Quick response

- ISO/MID certified

- 100+ customers trust

- 1-on-1 engineer support

- ASK SameGram

- Contact SameGram

- Metal Detector Checkweigher Selection Table

- Checkweigher Selection Registration Form

- Labeling technical parameters

- Mobile Phone

- Mobile Phone

- Mobile Phone

- Mobile Phone

- Mobile Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions