Weight Checking Solutions

In the pharmaceutical industry,do you want to ensure that every box of pre-packaged medicine is complete, intact and compliant before leaving the factory?

In the food industry,are you facing strict requirements on net content such as the German Pre-Packaging Act?

In the non-food, chemical, mechanical manufacturing or logistics industries,do you want to improve process efficiency, reduce errors and create more added value with the help of weight monitoring?

SameGram's intelligent checkweighing system has the dual advantages of high precision and high throughput, ensuring reliable support for customers in various industrial scenarios.

Quality Assurance in the Food Industry

In food production, weight control is not only related to production costs, but also directly affects consumer safety and brand reputation. In particular, under the premise of complying with strict regulations such as the European Food Safety Act (Regulation (EC) No 852/2004), manufacturers must avoid overfilling or underfilling. Samegram's dynamic checkweighing system can accurately weigh each package to ensure the quality and consistency of each product, while reducing waste and cost increases caused by improper packaging.

In addition, food production requires not only weight detection, but also the prevention of foreign objects from entering the package. Our automatic checkweigher system can be seamlessly integrated with additional modules such as metal detectors to ensure that foreign metal objects in the package are detected and removed in time, in accordance with EU food safety standards, ensuring consumer safety. If you want to ensure the consistency of quality of each product and comply with food safety regulations, and can also perfectly integrate with the original production line, then our SCF series food checkweigher is your best choice.

Learn more

Pharmaceutical Industry: Focus on Patient Safety

For pharmaceutical manufacturers, accuracy and compliance are critical. Pharmaceutical packaging must not only meet strict weight control standards, but also comply with quality management standards such as GMP (Good Manufacturing Practice) and GxP (Good x Practice). Samegram's dynamic checkweigher can be accurate to milligrams to ensure that the weight of each pharmaceutical package is within the specified range, and unqualified products are removed in a timely manner to prevent unqualified drugs from entering the market.

Our pharmaceutical checkweigher system can also be integrated with metal detectors, barcode scanning systems and labeling machines to provide full-range quality control to ensure the integrity and safety of pharmaceutical packaging. In addition, our checkweigher system is also suitable for explosion-proof environments and can meet the requirements of the pharmaceutical industry for special production environments.

Learn more

Underweighting does not save costs, while overweighting increases costs

In the cosmetics industry, raw materials are often expensive, so it is particularly important to ensure the accurate packaging of each product. Underweighting not only does not save costs, but may cause consumers to distrust the brand, which in turn affects sales and reputation. Overweighting means wasting precious raw materials, increasing unnecessary production costs, and reducing overall profits. Especially in the cosmetics industry, accurate weight control is crucial to the brand, because every drop of raw material waste may have a significant impact on costs.

Samegram's high-speed checweigher can effectively avoid overfilling or underfilling through high-precision weight detection, ensuring that each package meets strict weight standards and minimizes raw material waste. Combined with metal detectors and visual inspection modules, the cosmetic checkweigher system can also detect potential foreign body contamination in real time to ensure that every bottle of cosmetics meets hygiene and safety requirements. We help cosmetics manufacturers improve production efficiency, reduce raw material waste, and improve product quality and brand image, so that consumers can enjoy high-quality products while also getting a safe and reliable use experience.

Learn more

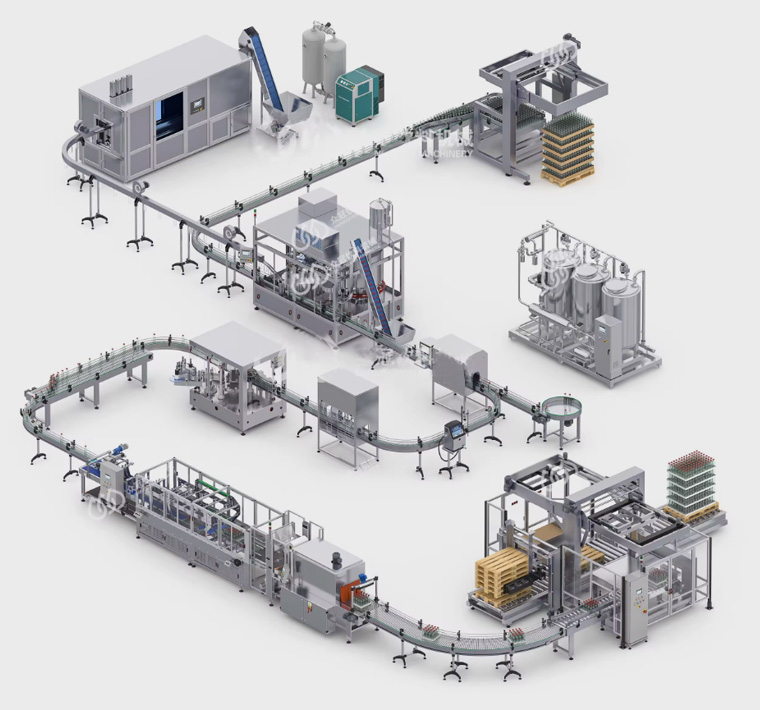

Efficiency and integration: improve production efficiency

Samegram's inline checkweigher not only has high performance, but can also be integrated with additional modules such as code scanning, labeling, metal detectors, etc. to form a comprehensive detection system to comprehensively improve production efficiency. This integration is not limited to a single device, it can also be seamlessly connected with other modules of the production line (automatic box packing machine, production line, automatic filling machine, vertical packaging machine, etc.) to form a complete intelligent production process.

Our weighing system adopts a modular design and can be customized according to the production needs of different customers, so as to provide flexible checkweigher solutions to meet the needs of different production environments. Whether it is a high-speed production line or a special occasion requiring high precision, Samegram's automatic checkweigher system can provide the best solution.

Learn moreRecommended checkweigher products

Provide the Most Suitable Checkweigher Solution According to Your Specific situation

Hygienic Checkweigher for Food

- performs food checkweighing for chips, candies, and dried fruits with high accuracy.

- Ideal for checkweigher food industry, it suits food, pharma, electronics, and agricultural applications perfectly.

- The food checkweigher also detects missing accessories like spoons, straws, and desiccants in packaging.

checkweigher with metal detector

- Designed for high-speed lines in checkweigher and metal detector for food industry applications.

- metal detector with food processing checkweighers, removing defective products quickly.

- Widely used in checkweigher for food industry, pharma, and daily chemical sectors.

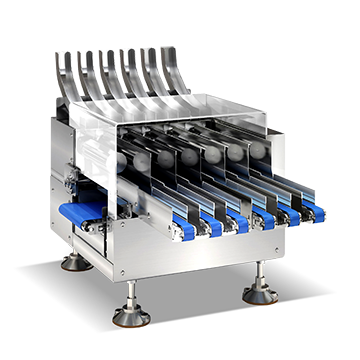

multi lane checkweigher

- Compact multi-lane structure.Ideal for snacks checkweighing machinery and seamless packaging line integration.

- Supports checkweigher pharmaceutical lines and pharma checkweighing automation

- Perfect for food, beverage, cosmetics checkweighing system, and daily chemical strip-pack applications.

High Precision Pharmaceutical Checkweigher

- Suitable for bottles, boxes, and pouches with high-speed motion checkweighing accuracy.

- Easy-to-use checkweigher conveyor ideal for pharma checkweighing and lightweight packaging.

- This pharmaceutical checkweigher ensures every product meets precise weight standards.

Successful Case

What Our Customers Say

- Snack and Confectionery Checkweighers

- Weighing systems for baking quality inspection

- C3 Series Heavy Load Checkweigher

- Packaging and non-packaging checkweigher systems

- Checkweighers in dairy production

- Inline checkweigher solutions

- Ready-to-eat food checkweigher

- Cosmetic checkweigher

- Dry environment checkweigher

- Dynamic checkweigher for various industries

- Food checkweigher for compliance

- Harsh environment checkweigher solutions

- Weight inspection equipment

- High performance checkweighers

- Hygienic checkweighers for food safety

- Dynamic checkweighers for continuous operation

- IP65 checkweighers

- Meat and poultry weight control

- Pharmaceutical checkweighers

- Automatic checkweigher systems

faq

Frequently Asked Questions

- Q: What is the weighing accuracy of SameGram machines?SameGram checkweighers provide high-precision weighing, with accuracy ranging from ±0.02 g to ±10 g, depending on model and load — ensuring reliable performance for both light and heavy products.

A:

SameGram checkweighers offer high-precision performance with weighing accuracy ranging from ±0.02 g to ±10 g, depending on the model and product weight. For example, our SC1-C-3523L1 model delivers up to ±0.02 g precision for small items, while heavy-duty mo±3–10 g accuracy for loads up to 30 kg.

- Q: How much space is required to install a checkweigher?The required space for installing in-motion checkweighers depends on product size, conveyor speed, and rejector type. Proper planning ensures smooth integration and future maintenance access.

A:

In-motion checkweighers installations typically require space for the checkweigher scale, conveyor infeed/outfeed, and reject mechanism. Most standard units fit into existing lines with minimal modifications. For accurate setup, refer to the checkweigher manual, which includes dimensions, safety zones, and service access guidelines. Our team provides checkweigher service and onsite checkweigher training to assist with layout planning. Proper spacing ensures accurate check weigh operations and simplifies future maintenance. Custom configurations are available for limited spaces or complex layouts. Contact us for a tailored installation plan based on your product and production environment.

- Q: How do checkweighers reject non-compliant products?A checkweigher reject system within checkweighing and rejection systems uses automated mechanisms—air jets, pushers, swing gates, or drop belts—to instantly remove off-spec products on the conveyor.A:In modern automated inspection and rejection systems, every product is weighed on an in-line checkweigher as it travels. Once weight falls outside the set tolerance, the checkweigher reject system engages. Lightweight items are diverted with a pneumatic rejection system (air jet), while heavier ones may be pushed off by actuated arms or gates. Fragile or sticky items drop gently via flaps or belts. This conveyor-based inspection and rejection system ensures real-time quality control, maintaining flow speed and minimizing product loss—a vital feature of contemporary conveyor reject system implementations.

- Q: Do I need to calibrate the checkweigher regularly?Yes, regular checkweigher calibration is essential to maintain accuracy, reduce error rates, and ensure compliance with quality standards, especially for hi-speed or high-performance checkweighers.

A:

Regular checkweigher calibration ensures your system maintains precise performance and operates within acceptable checkweigher tolerance limits. Over time, environmental changes, mechanical wear, and product variation can affect accuracy. Following a standard checkweigher calibration procedure—which includes placing certified test weights on the conveyor and adjusting the system accordingly—is critical for consistent results. For a hi-speed checkweigher or high performance checkweigher, calibration should be more frequent due to tighter tolerances and faster throughput. Proper calibration not only prevents overfill/underfill issues but also supports audits and traceability in regulated industries. We recommend weekly or monthly calibration, depending on your production intensity and compliance needs.

- Q: What certifications and quality standards does SameGram comply with?SameGram machines comply with international certifications like ISO, CE, and FDA, and meet food safety audit standards such as BRC and IFS.

A:

SameGram equipment is manufactured to meet international quality and safety standards, ensuring reliability in global markets. Our machines are designed in compliance with ISO-certified manufacturing practices and meet the food safety requirements of GFSI, BRC, and IFS audits. Many models are also built with CE-marked components and FDA-compliant materials for contact surfaces, making them suitable for the food, beverage, and pharmaceutical industries. This commitment to compliance ensures that SameGram systems can be seamlessly integrated into regulated production environments.

Ready to Build Your Own Solution?

Choosing SameGram means

Flexible customization

Perfectly adapt to existing systems

Rich experience

16 years of professional manufacturing precipitation

Free samples

Support remote viewing and sample testing

Fast delivery

standard products in stock, shipped on the same day

Extensive verification

5000+ customers trust, wide industry coverage

After-sales guarantee

2-year warranty, lifetime maintenance

- ASK SameGram

- Contact SameGram

- Metal Detector Checkweigher Selection Table

- Checkweigher Selection Registration Form

- Labeling technical parameters

- Mobile Phone

- Mobile Phone

- Mobile Phone

- Mobile Phone

- Mobile Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions