High-Precision Weighing and Inspection Systems for the Cosmetics Industry

The cosmetics industry is all about precision and appearance. Whether it’s lotions, creams, lipsticks or powders, every product must meet strict standards for net content, appearance and consumer safety.

A few grams too much can increase costs. Too little can lead to consumer complaints or even regulatory violations. Before any product hits the shelves, it must pass foreign matter testing to ensure consumer safety and compliance.

difficulty

Industry Challenges

Inaccurate net content

Overfilling = cost waste; underfilling = compliance risk.

The fine tolerances required for cosmetics cannot be met by manual or standard equipment.

Inconsistent packaging

Weight deviation affects user experience and brand image.

Metal contamination

Trace metal particles lead to recall and reputation damage risk.

Low detection efficiency

Manual inspection is slow and has large errors, which is not suitable for high-speed production.

Lack of data integration

Unable to connect with MES/ERP system, traceability is difficult.

Application Scenarios

Preventing Empty Packs in Lightweight Packaging

On earplug production lines, inline checkweighers ensure that every pack meets the target weight, eliminating empty or underfilled packages before they move into final warehousing.

Quality Assurance for Single-Sheet Facial Masks

Checkweighers provide precise weight control on facial mask production lines, guaranteeing consistent product quality and uniformity in each packaged sheet.

Ensuring Complete Accessory Packaging for Electronics

In cosmetic device production, such as mole removal pens, checkweighers verify that all accessories are included, preventing missing or insufficient components in each unit.

Accurate Weight Verification During Packaging

On isolation cream production lines, real-time weighing ensures that each product is correctly filled and packaged, supporting both regulatory compliance and brand reputation.

Weight and Contaminant Detection for Personal Hygiene Products

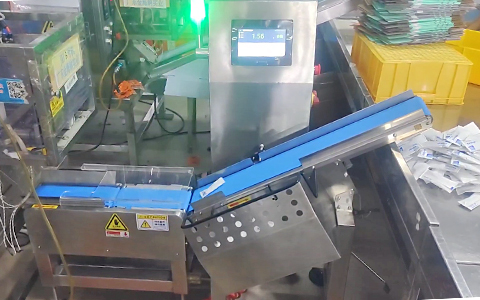

For individually packed hygiene items such as sanitary pad, checkweighers combined with metal detection systems safeguard product integrity before palletizing and warehousing.

Downstream Weight Control for Liquid Cosmetics

Installed after liquid filling machines, checkweighers monitor precise fill volumes and prevent unstable or overturned bottles, ensuring smooth downstream processing and reliable product presentation.

Recommended products

Boost Your Productivity with SameGram

Successful Cases

What Our Customers Say

Accurate weighing helps brands expand production steadily

"When we launched a new series of glass bottle serums, SameGram's high-precision checkweigher became an indispensable part of our production line. It not only ensures that the net content of each bottle of product is compliant, but also effectively avoids the cost waste caused by overfilling.

In the first quarter after going online, our customer return rate dropped by 90%, which made our quality team worry less."

Alba Deventola

Quality Manager of a Factory in Valencia, Spain

Smart integration, say goodbye to manual records

"SameGram helped us solve a long-standing pain point: the problem of manually recording product testing data.

Their cosmetics checkweighing system can be seamlessly connected with our MES system. Now every gram of our data can be traced, which greatly improves our digital management capabilities and provides strong support for our application for EU GMP certification."

Emma Reid

Production Director of a Factory in London, UK

Foreign body detection, protecting the brand bottom line

"SameGram's metal detector helped us successfully eliminate the hidden dangers of multiple tiny metal particle contaminations on a powder mask production line.

This ability to quickly identify and automatically remove saves us possible recall losses. For us, product safety is the core brand bottom line, and we believe in their technology."

Michiko Ono

COO of a cosmetics company in Kobe, Japan

Free Sample Test

We offer free sample testing and demonstration setups customized to your product type and packaging format!

Why Partner with SameGram for Smart Manufacturing

From labor-intensive to data-driven

Real-time tracking of every gram

Seamless access to MES/ERP

Modular Scalable Remote Ready

Future Proof Architecture with Room to Grow

Remote Line Assessment and Custom Support

Get a Free Solution Plan

Contact our team of experts for:

- Free line evaluation

- Customized product testing

- Customized machine configuration

- Request a free consultation or Book a live demo

- ASK SameGram

- Mobile Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions