Modular Rejector Devices for Product Rejection & Sorting

Samegram’s rejector systems are engineered for automated lines to remove defective, overweight, or contaminated products with speed and precision. The system supports multiple rejection methods—including swing arm, air blast, pusher, flipper, and drop-type ejectors—to suit various product shapes, weights, and packaging materials. Designed for flexibility, it ensures smooth integration into food, pharma, and industrial production lines, providing reliable reject & sorting solutions when combined with weighing or inspection systems. Additionally, the Povit Wheel Sorter is available for high-throughput parcel sorting in logistics, e-commerce, and warehouse operations, offering intelligent routing and reduced manual handling in demanding environments.

- Introduce

- Products

- Featured Products

- Support

- Cases

- FAQ

- Blog

Samegram Reject Systems for Intelligent Inspection

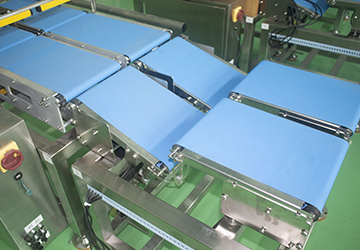

- Belt Drop for light products

- Flipper for directional rejection

- Up & Out for gentle handling

- Air Jet for high-speed items

- Pivot Wheel for logistics sorting

- Washdown-ready modular design

Multiple Reject Options

Supports swing arms, air jets, pushers, flippers, and drop types to handle diverse product forms and rejection needs.

Fast & Accurate Removal

Instant response to weight or contaminant signals ensures defective products are ejected precisely without interrupting production flow.

Gentle Handling Design

Custom reject structures protect fragile items like food packs, pharmaceuticals, or light parcels during high-speed ejection.

Logistics-Grade Sorting

Povit Wheel Sorter enables smart, high-speed diverging for e-commerce, express, and warehousing environments.

Rejector Device Product list

- Belt Drop Rejector

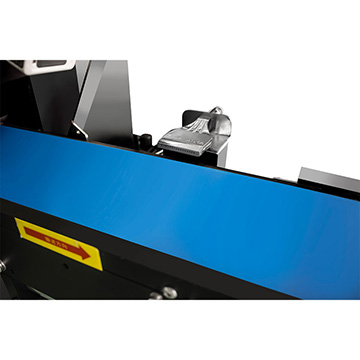

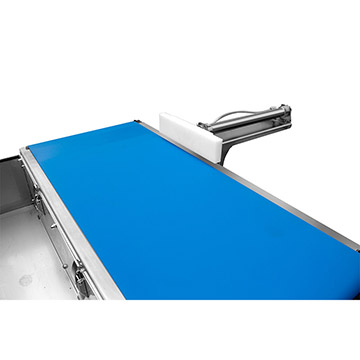

Samegram’s Belt Drop rejector is a high speed rejector using pneumatic lift rods to gently remove thin bags and flat products. Fast, efficient, and jam-free for continuous flow.

Swing Arm RejectorSamegram’s Pull-out rejector uses a fast swing-arm to efficiently remove defective boxed and bagged products up to 1kg. Reliable and durable, it ensures smooth, high-speed production.

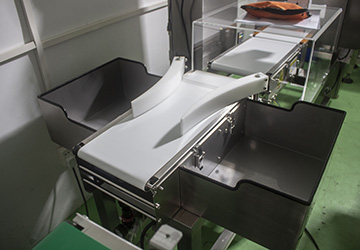

Up and Out RejectorSamegram’s Up and Down Flap Rejectors, used in checkweigher with rejector systems, ensure stable removal of soft, thick items like hot pot bases. Smooth pneumatic action prevents jams.

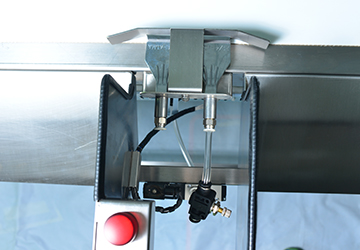

Air Jet RejectorSamegram’s Air Jet Rejectors use powerful air bursts to remove lightweight or low-density items. Ideal for fast-moving lines, these contact-free rejectors offer long service life with no wear parts.

Pusher RejectorSamegram’s Putter Rejectors pair with checkweigher with rejector systems to deliver accurate, mid-speed removal of heavy, boxed items. Ideal for detecting missing bottles or components in final packaging.

Roller Pusher RejectorRoller Pusher Rejector Systems work with inspection devices to reliably remove defective, hard-packed or boxed products at mid-speed. Perfect for rejecting missing manuals or incomplete items on production lines.

Pivot Wheel SorterSamegram’s pivot wheel sorter is a high-speed wheel sorter conveyor for logistics. This swivel wheel sorter offers reliable and accurate parcel diversion in smart warehouse operations.

Rejector Devices Selection & Comparison Guide

| Type | Structure | Suitable Products | Not Suitable | |

|---|---|---|---|---|

| Swing Arm Rejector | Rotating arm swings product sideways | Single-row, stable products | Soft/fragile packaging, multi-row products |

| Belt Drop Rejector | Single belt segment drops product | Soft, flat, or irregular-shaped products | Very heavy or extremely unstable products |

| Up and Out Rejector | First belt down, second belt up → larger drop space | Soft, thick, and irregular-shaped products | Extremely unstable or very fragile products |

| Air Jet Rejector | Compressed air blast | Light, small, low-density products | Heavy, dense, high-friction products |

| Pusher Rejector | Pneumatic/electric cylinder pushes product | Medium to heavy, regular shape; almost any weight | Extremely soft or highly irregular products |

| Roller Pusher Rejector | Pusher mechanism on roller conveyor | Medium-heavy, regular shape | Soft, fragile, irregular shapes |

| Pivot Wheel Sorter | Rotating wheel diverts product on roller conveyor | Logistics parcels for multi-channel sorting | Soft, fragile, multi-row |

Get free

SameGram Rejection & Sorting Devices Selection Guide

- Recommendations for weight check and labeling in different industries

- Key considerations before automation upgrade

- ROI analysis case of high-precision weight check system

Support

One-Stop Service

Customized solutions

High-speed rejector systems customized for various removal methods to maximize line efficiency and product safety.

Installation, commissioning, and diagnosis

Online tuning and troubleshooting to prevent false rejects and ensure fast response times.

Professional certification and technical support

Remote assistance ensuring rejector timing and accuracy meet strict production requirements.

Training and equipment maintenance

Detailed virtual training on rejector mechanisms, fault diagnostics, and routine maintenance procedures.

Related Cases

- Industry:

- Trading card manufacturing

- Equipment:

- High-precision dynamic checkweigher with push-rod rejector

- Country:

- Zhejiang, China

faq

Frequently Asked Questions

- Q: Where is your factory located?Our factory is located in southern China's manufacturing hub: No.33 Sanjiang Industrial Area, Hengli Town, Dongguan City, Guangdong Province, P.R. China.A:Our factory is located at:📍 No.33 Sanjiang Industrial Area, Hengli Town, Dongguan City, Guangdong Province, P.R. ChinaWe are based in the Pearl River Delta, near Guangzhou and Shenzhen, with convenient access for both domestic and international logistics. Customers are warmly welcome to visit our factory for on-site inspections or business discussions.

- Q: What are SameGram's main products?SameGram manufactures a range of automated weighing and inspection equipment, including checkweighers, sorting machines, labeling systems, and logistics scales, which are widely used in the food, pharmaceutical, and logistics industries.

A:

SameGram manufactures a wide range of automated weighing and inspection systems designed to improve production accuracy and efficiency. Our main products include:· Checkweighers – For high-speed, real-time weight detection and automatic rejection of non-compliant products· Weight Sorting Machines – Used to classify products into multiple weight ranges, ideal for seafood, poultry, and agriculture· Weighing & Labeling Machines – Integrated systems that automatically weigh, print, and apply labels in packaging lines· Logistics Weighing Equipment – Tailored for fast, accurate parcel weighing in express delivery and warehousing· Customized Weighing Solutions – Including multi-channel, static weighing, and combination systems for unique production needsThese products are widely used in industries such as food, medicine, cosmetics, logistics, e-commerce, and aquaculture. - Q: What industries does SameGram serve?SameGram's weighing and labeling systems are widely used in food, pharmaceuticals, cosmetics, logistics, aquaculture, and other fields, providing accurate and efficient solutions for various industries.A:SameGram's automated weighing, sorting, and labeling systems are widely used across a variety of industries, including:Food & Beverage – For weight control, classification, and labeling of packaged or bulk productsPharmaceuticals – Ensuring dosage accuracy and regulatory complianceCosmetics & Daily Chemicals – Used in production lines for filling weight verification and label trackingLogistics & E-commerce – Fast parcel weighing and barcode labeling for warehousing and fulfillmentAquaculture & Agriculture – For grading seafood, poultry, and fresh produce by weightPrinting & Publishing – Detecting missing pages or underweight items in book/manual productionElectronics & Hardware – For checking component completeness and assembly weight accuracyOur flexible systems support various conveyor types, product sizes, and line speeds, making them ideal for diverse production environments.

- Q: Are you a manufacturer or a trading company?SameGram is a professional manufacturer specializing in the design, production, and sales of automated weighing and inspection equipment. With in-house R&D and manufacturing capabilities, we provide high-quality customized solutions to meet various industrial needs.

A:

We are a specialized manufacturer of automated weighing and inspection equipment, founded in 2016, with over 15 years of industry experience, ISO9001 and CE certified.

- Q: How do you package your equipment?SameGram equipment is packed in export-grade wooden crates with shockproof and moisture-proof protection for safe global delivery.

A:

All SameGram equipment is packaged using export-grade wooden crates, ensuring safe delivery during international transportation. Each unit is securely fixed and protected with shock-absorbing and moisture-resistant materials to prevent damage from vibration, humidity, or impact.

- Q: What's your MOQ for your products?SameGram accepts trial orders with no MOQ—1 unit is welcome.

A:

SameGram has no strict MOQ requirement. We welcome trial orders starting from just 1 unit, especially for first-time customers who want to test product performance before scaling up.

Dynamic Checkweigher Insights

- Ultimate Dynamic Checkweigher Guide: Operation, Maintenance & TipsExplore our comprehensive dynamic checkweigher guide for setup, operation, troubleshooting, and maintenance. Boost accuracy and efficiency with SameGram's expert insights. Free consultation available!More

- Checkweigher & Labeling Integration Guide 2025: Key BenefitsDiscover how integrating checkweighers with weigh price labellers boosts accuracy, efficiency, compliance, and cost savings in food & pharma production. SameGram's solutions streamline your line.More

- Checkweigher with Metal Detector for Beverage Quality ControlDiscover SameGram's advanced checkweigher with metal detector for beverage production. Ensure accurate weights, detect contaminants, and boost efficiency in bottling lines. Explore benefits and custom systems today.More

- How Dynamic Checkweighers Boost Efficiency in Fruit Processing PlantsDiscover how dynamic checkweighers enhance fruit processing efficiency, reduce waste, and ensure compliance. Explore SameGram's high-precision solutions for optimal production.More

Contact Us

Get solutions

Get free quotes

Quick response

- ISO/MID certified

- 100+ customers trust

- 1-on-1 engineer support

- ASK SameGram

- Contact SameGram

- Metal Detector Checkweigher Selection Table

- Checkweigher Selection Registration Form

- Labeling technical parameters

- Mobile Phone

- Mobile Phone

- Mobile Phone

- Mobile Phone

- Mobile Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions