Custom Checkweigher and Inspection Solutions

Best solutions

Customized Dynamic Checkweighers to Your Needs

At SameGram, we understand that no two production lines are exactly alike. Whether you operate in the cosmetics, pharmaceutical, food and beverage or logistics industries, your workflow, space and regulatory needs are unique. That’s why we go beyond standard products and provide fully customization dynamic checkweigher and inspection solutions to meet your specific needs.

Customizable

Why Choose SameGram Customized Solutions?

Designed to Fit Your Production Line

From conveyor height and weighing range to multi-lane sorting and smart reject modules – every component can be adjusted or redesigned to match your product specifications, packaging format and throughput goals.

Intelligent Integration Into Your Digital Workflow

Our systems can be fully integrated with MES, ERP platforms, enabling real-time data traceability, automated reporting and full visibility of the entire manufacturing process.Support hardware interface: Ethernet port (RJ45), wireless wifi, RS232, RS485

Engineering Collaboration

SameGram’s engineering team works closely with your production and quality teams. Through site surveys, 3D layout planning, and functional simulations, we ensure the solution is right for your facility and your future.

Modular Architecture

Whether you need to combine checkweighing, metal detection, vision inspection, label printing or dimensional measurement, SameGram offers modular, scalable configurations to meet your needs.

Designed for Harsh and Hygienic Environments

From IP65-rated stainless steel construction to washdown designs for cleanroom applications, our systems are built to withstand the rigors of cosmetic filling rooms, pharmaceutical clean areas, and refrigerated logistics lines.

Our Customization Process:Tailored for You

Step 1

Initial Consultation & Needs Analysis

Understanding Your Needs:

①What We Do:We begin by discussing your specific requirements—product features, industry standards, and performance goals.

②How It Helps You:We help you clarify your needs and offer expert guidance to find the best solution, making sure we’re on the same page from the start.

Step 2

Tailored Solution & Pricing

We Craft a Solution That Works for You:

①What We Do: Based on your input, our engineers develop a personalized solution with clear pricing. We provide different options, so you can choose the best fit for your needs and budget.

②How It Helps You: You’ll get a transparent quote and clear roadmap of how we’ll meet your requirements—no surprises, just exactly what you need.

Step 3

Design & Prototyping

Visualizing Your Solution:

①What We Do: Our engineers will create a detailed design and prototype, ensuring everything works to perfection before production begins. We’ll share the design with you for feedback.

②How It Helps You: You get to see exactly how the solution will look and function, and can suggest any changes or adjustments to meet your expectations.

Step 4

Production

Building Your Custom Solution:

①What We Do: Once the design is finalized, we begin the production process. Our advanced manufacturing facilities ensure top-notch quality at every step.

②How It Helps You: You get a product that’s built to last and meets the highest industry standards, without any compromises on quality.

Step 5

Calibration & Testing

Ensuring Peak Performance:

①What We Do: After production, we conduct a series of rigorous tests and calibrations to ensure everything operates perfectly under real-world conditions.

②How It Helps You: We ensure your solution is ready for seamless integration into your production line, guaranteeing optimal performance.

Step 6

Delivery & Installation

On-Time, On-Target:

①What We Do: We ship your customized solution directly to your location and, if required, provide installation and setup. Our team ensures the equipment is running smoothly.

②How It Helps You: You get your solution delivered on time and ready to go, with no hassle and minimal downtime for your operations.

Success Stories

Customized Successful Industry Cases

- Germany

Beauty Cream Manufacturer

SameGram helped us streamline our skincare filling line by providing a multi-lane checkweigher with integrated metal detection and real-time data logging. The result? 28% increase in throughput, zero product recalls, and full compliance with EU cosmetics GMP standards.

Premium Skincare Brand

QA Manager

- India

Pharmaceutical OEM

We had very limited installation space and needed an all-in-one unit for weighing, label verification, and 21 CFR Part 11 compliance. SameGram designed a compact unit that saved 1.5 meters of line length and passed our validation with ease.

Contract Manufacturing Plant

Engineering Supervisor

- United States

Food Packaging Plant

SameGram was the only supplier that could offer a dual-lane weighing system with automatic rerouting and reject feedback. Their flexibility saved us thousands of dollars in product rework and increased customer satisfaction.

Global Consumer Goods Brands

Production Director

Our customers

They Chose SameGram

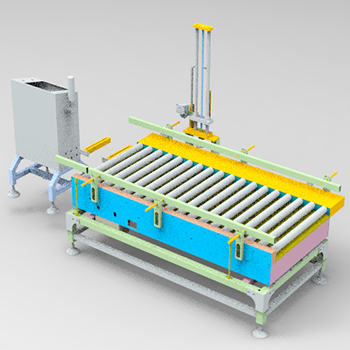

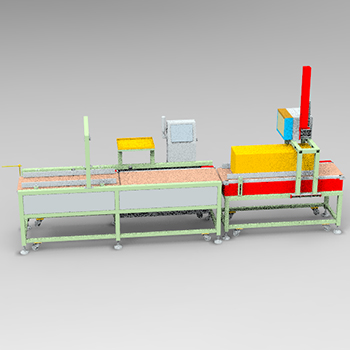

Customized Solutions at a Glance

Customized dynamic inspection and measurement products

Includes dynamic inspection and measurement products and sorting products, which are convenient for adaptation to various production environments, support small-scale transformation and large-scale implementation, and have multiple speeds and channels to choose from.

Start the project

Customized metal detectors

Design the most suitable metal detection equipment for industrial environments according to your project requirements, efficiently detect metal impurities, and ensure production safety and compliance.

Start the project

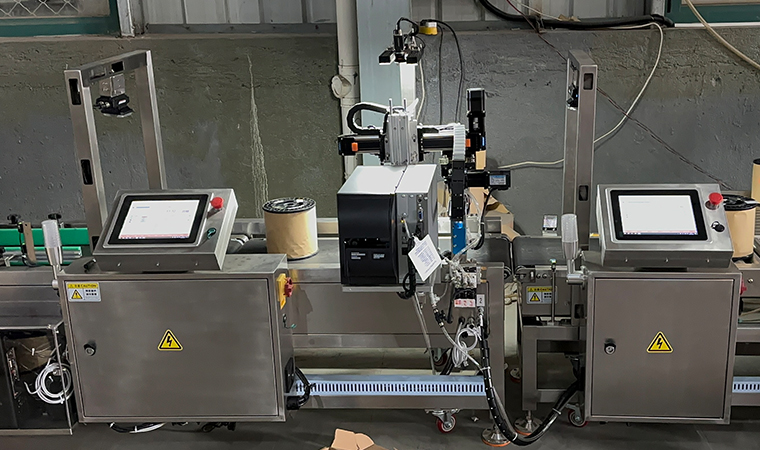

Customized code scanning and labeling

Supports linkage with integrated inspection and measurement products, combined into integrated inspection and measurement code scanning and labeling machines, with adjustable label position/speed/precision, and supports compliance system interaction protocols.

Start the project

Customized checkweigher combination system

Integrated inspection and measurement + metal inspection + code scanning + printing + sorting, integrating multi-functional modules into one machine, such as "metal inspection and re-inspection all-in-one machine" or "code scanning and labeling integrated inspection and measurement product", improving online automation and performance.

Start the projectReady to Build Your Own Solution?

Choosing SameGram means

Flexible customization

Perfectly adapt to existing systems

Rich experience

16 years of professional manufacturing precipitation

Free samples

Support remote viewing and sample testing

Fast delivery

standard products in stock, shipped on the same day

Extensive verification

5000+ customers trust, wide industry coverage

After-sales guarantee

12-month warranty, lifetime maintenance

- ASK SameGram

- Mobile Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions