Online weighing, foreign object detection, and labeling integrated solution

With over 15 years of experience in industrial weighing and inspection technology, we help companies improve production efficiency and achieve digital compliance management from production batching to logistics sorting through high-sampling-frequency DSP algorithms and modular design.

Common ChallengesUnderstand the key issues impacting your production efficiency.

Why Choose SameGram?

How We Work Together

Weight Checking:

Recommend suitable products based on your platform characteristics and target groups.

Metal Detection:

Multi-frequency detection technology with automatic phase compensation effectively suppresses the "product effect." Supports Fe, Non-Fe, and SUS detection.

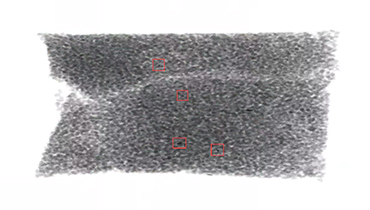

X-Ray Inspection:

The penetrating imaging algorithm can detect metals, stones, glass, ceramics, and high-density plastics, and supports the inspection of aluminum foil packaging.

Weight Batching:

Multi-head/combination weighing platform logic optimizes the feeding curve. Reduces manual intervention and ensures static/dynamic proportioning errors are within ±0.5%.

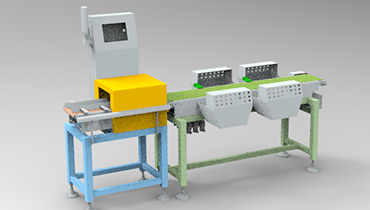

Graded By Weight:

High-speed multi-stage sorting (up to 16 stages). Suitable for standardized grading of irregular materials such as meat, seafood, fruits and vegetables.

Customization:

From PLC communication protocol interoperability (Modbus/TCP, EtherNet/IP) to the structural design of special material conveying mechanisms.

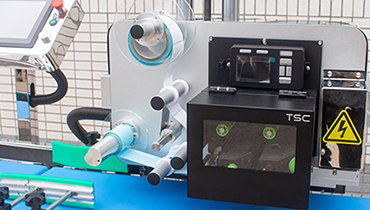

Coding & Inspection:

Integrates high-speed printing and coding with visual OCR recognition. Real-time detection of mislabeled, missing, and damaged barcodes ensures a 100% label pass rate.

Logistics DWS:

Integrates 3D laser rangefinder and industrial barcode reader camera. Processes volume, weight, and label information in milliseconds, and uploads data directly to WMS.

Reject & Sorting:

Diverse rejection devices: air-blowing, push-rod, and swing-arm types. Ensures product integrity and precise diversion even at high speeds.

Solutions We Provide for Enhanced Efficiency

Customization Solutions

Tailor scales to your unique needs, reducing downtime by 25%. Flexible integration with existing systems. Scalable for any product type.

Weight Checking

High-speed,accurate checks. Reduces waste by up to 30%. Ensure compliance with precise weight verification, minimizing errors

Accurate Weight Batching

Optimize batching with precision, boosting throughput by 20%.Consistent portion control. Automated for efficiency.

Graded By Weight

Sort products by weight for quality control,improving consistency.Custom grading parameters. Enhances product uniformity.

Metal Detection

Protect your products with advanced detection, ensuring safety.High-sensitivity sensors. Reduces contamination risks.

Coding, Labeling & Inspection

Streamline labeling with automated inspection, preventing recalls. Accurate label placement. Real-time error detection.

Weighing for DWS System

High-precision DWS weighing solutions for logistics, ensuring accuracy, speed, and integration for efficient parcel processing.

Reject & Sorting

Automate defective product rejection, improving line efficiency.Fast, precise sorting.Minimizes manual intervention.

Some very successful cases

faq

Frequently Asked Questions

- Q: What information is required for a custom checkweigher order?Learn what key details you need to provide—like product size, weight range, speed, and layout—to request a custom checkweigher or inspection system from SameGram. Fill out the online form for tailored solutions.

A:

To help us design the most suitable weighing or inspection solution for your needs, please provide the following:· Product dimensions· Weight range· Production speed· Production line layoutFor a faster and more accurate recommendation, we encourage you to fill out our Product Selection Form here: - Q: What standard weighing solutions does SameGram offer?SameGram provides industry-specific checkweighing and inspection solutions tailored to sectors like food, pharmaceuticals, daily chemicals, logistics, and electronics.

A:

SameGram offers checkweighing and inspection solutions for industries such as food, pharmaceuticals, daily chemicals, logistics, and electronics.

- Q: Can I customize the size, conveyor height, or label printer position?SameGram offers flexible customization of machine size, conveyor height, label printer position, and more to match your production line.

A:

Yes. SameGram supports a wide range of customizations to fit your production line needs, including:· Machine size and conveyor dimensions· Conveyor height to match existing systems· Label printer position and direction (top, side, bottom, or angle)· Other options like sensor placement, reject mechanism, and software layoutOur engineering team will evaluate your requirements and provide tailored solutions accordingly. - Q:What communication interfaces and software systems do your mechanical equipment support?SameGram devices support multiple communication interfaces including RS232, Ethernet, USB and digital I/O, and can be integrated with ERP and MES systems.

A:

SameGram devices support a variety of industrial communication interfaces, including:· RS232 / RS485· Ethernet (TCP/IP)· USB port· Digital I/O signalsThese interfaces support connection to factory-level management systems such as ERP and MES. - Q: What is a dynamic checkweigher and how does it work?A dynamic checkweigher is an inline weighing system that checks product weight during movement and rejects non-compliant items in real time.

A:

It's a vital tool in the checkweighing industry used for ensuring product weight accuracy. A dynamic checkweigher operates by weighing items in motion using load cells. Based on the checkweigher principle, the system compares actual weight to target limits and triggers rejection if outside range. Common checkweigher scale uses include food, pharma, and logistics. Each model belongs to a checkweigher grade based on accuracy and speed, helping manufacturers maintain quality control and reduce product giveaway.

- Q: What should I do if the machine malfunctions?SameGram offers reliable support for equipment malfunctions, including remote diagnostics, spare parts shipping, and on-site repair services to minimize downtime.

A:

If a malfunction occurs, SameGram provides comprehensive after-sales support including remote diagnostics, spare parts delivery, and on-site troubleshooting and repair by our engineers.

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions

Ready to Build Your Own Solution?

Choosing SameGram means

Flexible customization

Perfectly adapt to existing systems

Rich experience

16 years of professional manufacturing precipitation

Free samples

Support remote viewing and sample testing

Fast delivery

standard products in stock, shipped on the same day

Extensive verification

5000+ customers trust, wide industry coverage

After-sales guarantee

2-year warranty, lifetime maintenance

- ASK SameGram

- Contact SameGram

- Metal Detector Checkweigher Selection Table

- Checkweigher Selection Registration Form

- Labeling technical parameters

- Phone

- Phone

- Phone

- Phone

- Phone