Buying an X-ray inspection system is often worth it: food and pharma companies have reported annual savings of $80,000–$400,000 from reduced recalls, less waste, and improved efficiency, allowing many to recoup the machine cost within 1–2 years, making it a high-ROI investment.

Home / Coding labeling and label inspection solutions

Coding, Labeling and Label Inspection

Comprehensive Solutions for Coding, Labeling, and Label Inspection to Ensure Accuracy and Compliance.

Labeling:

Are manual labeling inefficiencies, errors, and slow speeds hindering your production, making product traceability difficult and impacting competitiveness? Do frequent label changes add significant cost and time?

Coding:

Are blurry, faded codes damaging your brand and traceability? Do frequent coder breakdowns and high maintenance costs slow production? Is your coding solution inflexible for diverse materials, or struggling to meet strict regulations?

Label Inspection:

Are label errors, missing information, or unreadable barcodes causing recalls and losses? Is manual inspection inefficient, prone to errors, affecting quality? How do you ensure every label is perfect and compliant, with automated traceability?

Enhance Packaging Accuracy With Integrated Coding, Labeling, And Inspection Modules, Built Into Checkweigher Systems.

In modern industrial packaging, isolated coding, labeling, or inspection often leads to inefficiencies, traceability issues, and labeling errors. Our modular solutions integrate real-time printers, industrial coders, and label inspection scanners directly into checkweigher systems—creating weight-labeling, weight-coding, and scan-labeling combinations for seamless performance.These intelligent systems support ERP/MES connectivity, enabling one-to-one product tracking, real-time label generation, and automatic validation. Designed for dynamic, multi-product environments, our solutions reduce human intervention and error, while boosting efficiency, compliance, and traceability. Whether you need high-speed label printing, precision coding, or inline label inspection, we offer the technology to keep your production moving flawlessly.

Why Your Labeling Process Keeps Falling Behind—and How Integrated Labeling Fixes It

You know the problem—labels that aren’t aligned, printed too early, or applied too late. Then comes the manual intervention, wasted time, and rejected products. Our automatic labeling machine solves this by combining real-time printing with robotic label application, directly inside your checkweigher system. It works in sync with production, printing data live, applying precisely—no lag, no touch-ups, no babysitting required.

If you’re managing multiple SKUs or short runs in food, pharma, or consumer goods, this matters. The automatic label applicator machine links with your MES or ERP, enabling batch-specific labels, one-to-one traceability, and total automation. It handles bottles, bags, boxes—whatever you run. You get speed, accuracy, and labeling that never slows you down again.

contact us

Batch Code Errors Are Silent Profit Killers—Stop Them With Real-Time Inkjet Coding

Ever had a batch recalled because of a missing or unreadable code? Or a whole day’s worth of products stuck because the printer was off by a few seconds? With our automatic inkjet printer built into your checkweigher, those problems disappear. It prints on the fly—batch numbers, expiry dates, serials—accurately and instantly, triggered by product movement and live system data.

In industries where traceability is non-negotiable—like ready-to-eat foods, cosmetics, or chemicals—this isn’t just a nice-to-have, it’s mission-critical. Our system adapts to your line speed, connects with your production data, and works in harsh environments. You get coding that’s sharp, legal, and in the right place—without halting production or adding staff.

skip to product

What Happens When a Barcode Can't Be Read? Your Entire Supply Chain Feels It

You scan a product and nothing happens. Or worse—a wrong code routes it to the wrong warehouse. This isn’t rare. That’s why our automatic barcode scanner module doesn’t just scan—it verifies. Integrated into your checkweigher, it checks every label in real time. If there’s a misprint, smudge, or mismatch, the product is flagged or rejected before it causes trouble.

For sectors like pharma, retail logistics, or export compliance, one unreadable barcode can halt an entire process. Our automatic barcode scanner machine supports multi-format scans, auto-triggering, and fast decoding—without needing a separate station or operator. It’s the last line of defense before your product hits the box. And it works.

contact us

Not All Packaging Lines Are Created Equal—That's Why We Build Around Yours

Need labels applied to the side of a round bottle? A QR code printed underneath a box? Or a scan to verify it all happened? We don’t sell one-size-fits-all. Our modular systems let you choose—labeling, inkjet printing, scanning—and integrate them into a checkweigher platform customized for your real production flow.

We adjust the scale size to fit your samples, match label dimensions to your design, and configure application direction—top, bottom, left, or right. Whether you're producing cosmetics, pet food, or automotive parts, we tailor every detail: your modules, your data flow, your layout. No assumptions. No compromises. Just a system that fits like a glove.

customize nowRecommended products

We Provide the Most Suitable Solution According to Your Specific situation

Automatic Labeler

- Real-time dynamic labeling with an integrated automatic labeling machine for efficient traceability.

- Compact and ERP-ready automatic label applicator machine for multi-format packaging environments.

- Cost-saving, low-error automatic labeling machine ideal for small-batch or flexible production lines.

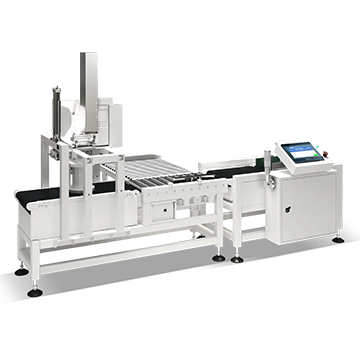

Three-Axis Automatic Labeler

- Compact industrial weighing and labelling systems save floor space and adapt to tight production areas.

- The weigh price labeler supports fast product switching with accurate and consistent label placement.

- Three-axis design enables wide labeling angles, solving fixed-position limits in conventional machines.

Advanced Weigh Price Labeler

- Supports weighing labelling and scanning software for packaging traceability and label verification.

- Flexible automatic label applicator machine enables dynamic labelling across diverse packaging formats.

- Real-time weigh price labeling eliminates mismatches between products and outer packaging.

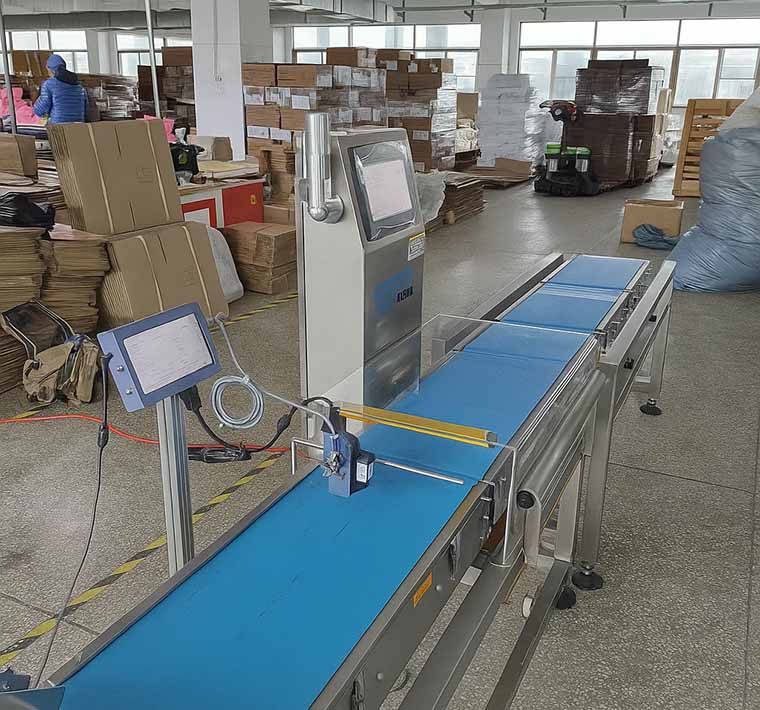

Checkweigher with Inkjet printer Combination System

- High-precision weighing and conveying improve accuracy, reducing costly packaging errors and waste.

- Automatic inkjet coding synchronizes with production, eliminating manual errors and boosting throughput.

- Photoelectric sensor enables dynamic weighing and rejects defective products instantly on the line.

Successful Cases

What Our Customers Say

Positive reviews from all over the world, trusted by hundreds of customers

- automatic weighing label

- weighing labeling machine

- print label system

- high precision labeling

- production line labeling

- food packaging label

- pharmaceutical label machine

- carton label solution

- dynamic weighing label

- ERP weighing label

- weighing inkjet printer

- high-speed inkjet coding

- synchronized inkjet printer

- food packaging inkjet

- real-time inkjet printing

- batch traceability printer

- dynamic coding printer

- production line inkjet

- multifunction inkjet printer

- ERP inkjet printer

- weighing barcode scanner

- high precision scanner

- barcode inspection system

- dynamic barcode scanner

- production line scanner

- barcode verification system

- quality control scanner

- food traceability scanner

- ERP barcode scanner

- automatic reject scanner

faq

Frequently Asked Questions

- Q: What is a dynamic checkweigher?Dynamic weighing ensures 100% inline inspection.A:Dynamic checkweigher automatically weighs products while moving on a conveyor, without stopping production.

- Q:Can the system be integrated with my production line?X-ray inspection systems can be integrated with production lines, supporting PLC/MES control, automatic reject mechanisms, and data reporting for seamless quality control.

A:

Yes, modern X-ray inspection systems are designed for production line integration. They can connect to PLC and MES systems, allowing automatic control, real-time data monitoring, and quality reporting. Most systems also support reject mechanisms to remove contaminated or defective products without stopping the line, ensuring efficient, continuous operation while maintaining high detection accuracy.

- Q:How accurate are X-ray inspection systems?Accuracy depends on energy, detector, and algorithms; dual-energy and AI improve material discrimination and lower false positives.

A:

X-ray inspection systems are highly accurate, typically detecting contaminants as small as 0.5–1.0 mm, depending on product type, packaging, and system settings. Modern systems with dual-energy or AI-based image analysis can reliably distinguish between different materials (metal, glass, stone, bone, plastic) and reduce false rejects. Accuracy also depends on proper calibration, line speed, and operator maintenance.

- Q:In which industries can Samegram's X-ray inspection systems bse used?SameGram X-ray inspection systems are designed for the food industry, including packaged, bulk, and seafood products, and can detect contaminants such as metal, glass, stones, bones, and hard plastics, ensuring product safety and quality.

A:

①primarily designed for the food industry, including:

Packaged foods (bottled or canned products)

-

- Bulk materials (grains, coffee, tea, and other loose products)

-

Seafood (fish fillets, fish bones, and fish spines)

②These systems can detect a wide range of foreign objects and contaminants, such as:

-

Metal fragments (iron, stainless steel, copper, etc.)

-

Glass shards

-

Stones or small rocks

-

Bones or bone fragments (e.g., fish bones)

-

High-density plastics or hard plastic pieces

-

- Q:Is investing in X-ray inspection worth it?X-ray inspection systems quickly pay for themselves by reducing recalls, cutting waste, and improving efficiency, delivering a strong ROI for food, pharma, and electronics manufacturers.

A:

- Q:When should I use 3D/CT instead of 2D X-ray?Use 3D/CT for complex internal geometry, failure analysis, or precise metrology when 2D images aren’t sufficient.

A:

Use 3D/CT for complex internal geometry, failure analysis, or precise metrology when 2D images aren’t sufficient.

Ready to Build Your Own Solution?

Contact us today to design a checkweighing and inspection system that fits perfectly—because your production needs to be accurate to every gram.

Choosing SameGram means

Flexible customization

Perfectly adapt to existing systems

Rich experience

16 years of professional manufacturing precipitation

Free samples

Support remote viewing and sample testing

Fast delivery

standard products in stock, shipped on the same day

Extensive verification

5000+ customers trust, wide industry coverage

After-sales guarantee

2-year warranty, lifetime maintenance

- ASK SameGram

- Contact SameGram

- Metal Detector Checkweigher Selection Table

- Checkweigher Selection Registration Form

- Labeling technical parameters

- Mobile Phone

- Mobile Phone

- Mobile Phone

- Mobile Phone

- Mobile Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions