Smart Weighing Scale for DWS System

Insufficient Weighing Accuracy Affecting Operational Efficiency? Traditional weighing equipment has limited accuracy, resulting in package sorting errors, increased operational costs, and customer complaints. Our high-precision weighing module can achieve weighing accuracy of ±0.1g within 2kg and ±5g-10g within 50kg in high-speed application scenarios of 90m/min, ensuring data reliability.

Equipment Integration Difficulties Hindering System Upgrades?

Existing DWS system components have poor compatibility and complex integration. We provide standardized interfaces and modular design for plug-and-play functionality, greatly simplifying the integration process.

High-Throughput Processing Requirements Difficult to Meet?

Business growth brings high-throughput processing demands that place higher requirements on equipment performance. Our dynamic weighing technology supports processing hundreds of packages per minute, meeting high-speed operation needs.

High-Precision DWS Weighing Solutions for Logistics Efficiency

Precise and Efficient DWS Weighing Solutions

We specialize in providing advanced weighing modules for logistics DWS (Dimensioning, Weighing, Scanning) systems, which integrate volume measurement, weight measurement, and OCR label recognition. Through innovative technology and precision engineering, we ensure exceptional weighing accuracy and stability in high-speed logistics and warehousing environments.

🎯 Ultra-High Precision Weighing

Utilizing advanced strain gauge sensor technology with high-precision AD converters, we achieve ±5g weighing accuracy to meet stringent industry standards.

⚡ Dynamic Weighing Capability

Supporting high-speed package weighing in motion with response times under 100ms, ensuring accurate measurements without stopping the conveyor.

📦 DWS Functionality Integration

Volume Measurement: Accurately measures both regular and irregularly shaped parcels.

Weight Measurement: Built-in scale delivers precise weight data.

OCR Label Recognition: Integrated cameras or scanners read barcodes and printed text for efficient tracking.

🔧 Modular Design

Standardized interface design supporting RS-485, Ethernet, and multiple communication protocols for seamless integration with various DWS systems.

Core Technology Advantages

🔬High-Precision Sensor Technology

Utilizing imported high-precision strain gauge sensors with advanced signal processing algorithms, achieving microgram-level weight detection capability and ensuring measurement stability under various environmental conditions.

⚡Fast Response Algorithm

Proprietary dynamic weighing algorithm using multi-point sampling and intelligent filtering technology to achieve accurate weighing at high speeds with millisecond-level response times.

🛡️Industrial-Grade Reliability

Designed to industrial-grade standards with excellent environmental adaptability and long-term stability, ensuring reliable operation in harsh industrial environments.

🔗Smart Integration Interface

Providing multiple standardized communication interfaces and open APIs, supporting seamless integration with mainstream DWS systems, WMS, and ERP systems for real-time data transmission and processing.

Features & Advantages

🎯 Precision Assurance

Ultra-High Precision Weighing: ±1 g accuracy ensures reliable package weight data, reducing shipping disputes and customer complaints caused by weight errors.

Automatic Calibration Function: A built-in automatic calibration system performs regular zero-point and span calibration, ensuring measurement accuracy stability during long-term use.

⚡ Efficiency Enhancement

High-Speed Dynamic Weighing: Supporting dynamic weighing at conveyor speeds up to 2m/s, processing 200+ packages per minute, significantly improving sorting center processing capacity.

Instant Data Output: Immediate data output upon weighing completion without waiting for stabilization time, working synchronously with scanning and measuring modules.

💰 Cost Optimization

Reduced Manual Intervention: Fully automated weighing process reduces manual operation requirements, lowering labor costs while avoiding human operational errors.

Predictive Maintenance: Built-in fault diagnosis function monitors equipment status in real-time, providing early warning of potential issues to reduce unexpected downtime losses.

🔧 Integration Convenience

Plug-and-Play Design: Standardized mechanical and electrical interfaces support rapid installation and replacement, minimizing system integration time and costs.

Strong Compatibility: Supporting equipment integration with mainstream DWS system manufacturers, providing customized adaptation services to ensure perfect integration with existing systems.

Application Scenarios & Industry Solutions

📦E-commerce Logistics Centers

Providing high-precision weighing solutions for major e-commerce platform sorting centers, supporting massive package processing, ensuring shipping cost calculation accuracy, and improving customer satisfaction.

40% Processing Capacity Increase 99.9% Weighing Accuracy 85% Reduction in Shipping Disputes

🚚Express Sorting Centers

Suitable for automated sorting lines of major express companies, enabling real-time package weight collection and data upload, supporting automatic sorting and routing planning by weight.

60% Sorting Efficiency Increase 99.8% Data Accuracy Rate 50% Labor Cost Reduction

🏭Manufacturing Warehouses

Providing precise inbound and outbound weighing management for manufacturing enterprise finished goods warehouses, ensuring inventory data accuracy, supporting lean production and supply chain optimization.

99.5% Inventory Accuracy 70% Inventory Efficiency Increase 30% Loss Control Improvement

🏥Pharmaceutical Logistics

Meeting strict requirements for weighing accuracy and data traceability in the pharmaceutical industry, ensuring weight monitoring and quality control during drug distribution processes.

100% Compliance, Complete Traceability, 95% Quality Risk Reduction

Diverse Product Portfolio: Meeting Various Logistics Industry Needs

We provide comprehensive weighing equipment to suit diverse production environments and product characteristics:

High‑Speed Dynamic Weighing Scale

- This high-speed dynamic weighing scale handles 60kg parcels with 10-30g accuracy for logistics.

- Its 1200mm×800mm platform integrates with DWS systems via Ethernet/RS485, processing 200 pieces per minute.

- Designed for durability, it supports automated sorting in distribution centers and 3PL operations reliably.

Large Parcel Dynamic Weighing Scale

- This large parcel dynamic weighing scale features a 2000×1500mm platform for oversized packages.

- It integrates barcode scanning, volume measurement, and precise weighing for efficient logistics operations.

- Customizable and reliable, it supports high-throughput customs and warehouse processes with minimal manual handling.

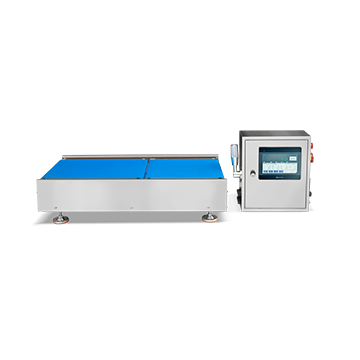

DualScale for Dynamic Parcel Weighing

- This dual-platform dynamic weighing scale ensures high-throughput parcel processing with precise real-time weight capture.

- It handles various parcel sizes, minimizing errors and congestion in fast-paced logistics environments.

- Integrated with scanners and sorters, it streamlines shipping operations for enhanced efficiency and accuracy.

High-Precision Dynamic Weighing Scale for Small Parcel

- This high-precision dynamic weighing scale ensures accurate weighing of small parcels up to 5kg.

- It features a 600mm×550mm platform, integrating seamlessly with automated sorting and scanning systems.

- Designed for e-commerce, it offers fast, reliable performance with customizable rejection modes for efficiency.

- Dynamic checkweigher

- Logistics weighing and sorting machine

- Automatic checkweigher

- High-speed weighing equipment

- Conveyor weighing machine

- Dynamic weight inspection

- Parcel weighing system

- In-line weighing equipment

- Weighing and sorting system

- Automatic weighing solution

- Intelligent weighing and sorting

- Logistics automation weighing

- Courier parcel checkweigher

- Weighing conveyor line

- Checkweighing system

- DWS system

- Dimensioning weighing scanning

- 3-in-1 parcel equipment

- Parcel DWS solution

- Automatic dimension measurement

- Barcode scanning and weighing system

- Multifunctional DWS device

- Logistics smart sorting DWS

- Express parcel weighing and scanning

- E-commerce warehouse DWS

- Parcel data capture system

- Automated DWS equipment

- Dimensional weight calculation system

- Express sorting automation

- Logistics data collection terminal

faq

Frequently Asked Questions

- Q: Can your automated machinery and equipment support the entire line docking solution?SameGram equipment supports full production line integration—connecting with packaging, labeling, ERP/MES systems and supporting code spraying, barcode scanning, and synchronized control.A:Yes. SameGram's systems are designed for seamless full-line integration, allowing smooth connection with upstream and downstream production equipment:· Connectivity with packaging, filling, and labeling machines for continuous operation.· Multiple communication interfaces (RS232/485, Ethernet) enabling interaction with factory systems like ERP and MES.· Support for online code spraying, barcode reading, rejection mechanisms, and more to build a cohesive manufacturing line.Our engineering team offers customized solutions to ensure synchronized data flow, real-time control, and production transparency across the entire line.

- Q: Does your machinery support remote monitoring and multi-language interfaces?SameGram machines support remote monitoring and multi-language touch screen interfaces, enhancing global usability and real-time control.

A:

Yes. SameGram equipment supports:✅ Remote monitoring – via Ethernet or RS485 connection, enabling real-time status viewing, data access, and remote diagnostics.🌐 Multi-language interface – touch screen HMI can be set to various languages, the default is Chinese and English, making it user-friendly for international teams.These features help improve production transparency, global usability, and maintenance efficiency. - Q: Where is your factory located?Our factory is located in southern China's manufacturing hub: No.33 Sanjiang Industrial Area, Hengli Town, Dongguan City, Guangdong Province, P.R. China.A:Our factory is located at:📍 No.33 Sanjiang Industrial Area, Hengli Town, Dongguan City, Guangdong Province, P.R. ChinaWe are based in the Pearl River Delta, near Guangzhou and Shenzhen, with convenient access for both domestic and international logistics. Customers are warmly welcome to visit our factory for on-site inspections or business discussions.

- Q: Can I test my products on a checkweigher or metal detector before purchase?We offer free sample testing services to help customers verify equipment performance and compatibility before purchase, ensuring the best solution.A:Yes. Our machines can provide free testing for samples you send to us. Simply ship your samples to our facility, and we will conduct tests based on your product specifications. You will receive a detailed testing video, data report, and our recommended optimal solution. This helps you confirm equipment compatibility and performance before purchase, reducing procurement risks.

- Q: Can I request a Proforma Invoice (PI) or Commercial Invoice (CI)?SameGram provides full export documentation, including PI, CI, PL, and CO, to support your international order and customs clearance process.

A:

Yes. We provide a complete set of export documents upon request, including the Proforma Invoice (PI), Commercial Invoice (CI), Packing List (PL), and Certificate of Origin (CO) to support your international trade and customs clearance needs.

- Q: What should I do if the machine malfunctions?SameGram offers reliable support for equipment malfunctions, including remote diagnostics, spare parts shipping, and on-site repair services to minimize downtime.

A:

If a malfunction occurs, SameGram provides comprehensive after-sales support including remote diagnostics, spare parts delivery, and on-site troubleshooting and repair by our engineers.

Ready to Build Your Own Solution?

Choosing SameGram means

Flexible customization

Perfectly adapt to existing systems

Rich experience

16 years of professional manufacturing precipitation

Free samples

Support remote viewing and sample testing

Fast delivery

standard products in stock, shipped on the same day

Extensive verification

5000+ customers trust, wide industry coverage

After-sales guarantee

2-year warranty, lifetime maintenance

- ASK SameGram

- Contact SameGram

- Metal Detector Checkweigher Selection Table

- Checkweigher Selection Registration Form

- Labeling technical parameters

- Mobile Phone

- Mobile Phone

- Mobile Phone

- Mobile Phone

- Mobile Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions