Home / All / Conveyor Metal Detector / Aluminum Foil Metal Detector for Food Packaging Line DD-220 series

Aluminum Foil Metal Detector for Food Packaging Line DD-220 series

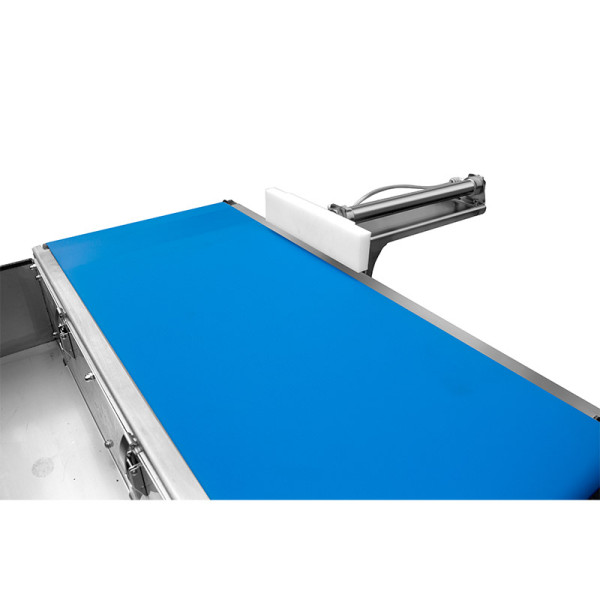

DD-220 is a food conveyor metal detector designed for aluminum foil packaging,with high sensitivity and easy integration.

Detail Information

Detail Information

Aluminum Foil Metal Detector for Food Packaging Line DD-220 series

Introduction

The DD-220 Aluminum Foil Pack Metal Detector is engineered specifically for products wrapped in aluminum foil or metallized film—where conventional metal detectors fail due to packaging interference. Built for seamless integration into conveyor-based production lines, it provides accurate ferrous metal detection even when products are fully foil-sealed.

Its multi-coil detection technology delivers stable sensitivity while keeping the machine compact, making it easy to fit into existing conveyors. The system supports multiple reject options—such as flap, pusher, or reverse belt—allowing manufacturers to match different product formats and line speeds.

Designed to meet IFS and HACCP requirements, the DD-220 offers reliable performance for final-stage inspection, including post-packaging checks, pre-shipment quality control, and integrated weighing or labeling stations. With a robust stainless-steel conveyor, modular structure, and simple cleaning access, it provides dependable contamination control for food, pharmaceuticals, and other industries dealing with foil-packed goods.

Aluminum Foil Metal Detector for Food Packaging Line DD-220 series Features

Aluminum Foil Metal Detector for Food Packaging Line DD-220

series Technical Parameters

| Product model DD-220 series | 3008 | 3012 | 4008 | 4010 | 4012 | 4015 | 4020 | 4025 | |

| Passing height | 300 (customizable) | ||||||||

passing width | 100 | 120 | 150 | 200 | 250 | 300 | 350 | 400 | |

Standard detection sensitivity | magnetic ball | 0.6 | 0.8 | 1.0 | 1.2 | 1.5 | 2.0 | 2.5 | 3.0 |

| stainless steel ball | 2.5 | 3.0 | 3.0 | 3.5 | 3.5 | 3.5 | 4.0 | 4.0 | |

| Alarm mode | The conveyor belt stops automatically when the sound and light alarm is sounded. When the automatic rejection structure is selected, the conveyor belt stops automatically. | ||||||||

Machine materials | 304 stainless steel | ||||||||

Belt speed | 27 m/min | ||||||||

Applicable environment | Temperature: 18-50ºC, Humidity: 30-90% | ||||||||

Body size | 1400×750×1100mm | ||||||||

Machine weight | About 200KG | ||||||||

Available Rejection Systems for Aluminum Foil Metal Detector series

Fast swing arm works with checkweigher or metal detector systems to remove defective boxes and bags up to 1 kg.

Samegram’s Belt Drop rejector is a high-speed rejector that uses pneumatic lift rods to gently remove thin bags and flat products.

Up and Out Rejector for checkweigher and metal detector systems — stable, gentle, and precise for soft or thick products.

The heavy-duty pusher rejector pair with checkweigher systems to deliver accurate, mid-speed removal of heavy, boxed items.

* The above sensitivity parameters are the test results when the machine is empty and has no environmental interference. The actual application may be slightly different due to the interference of the use environment and the composition of the object being tested.

File Downloads

For more product related parameter files, please contact us.

Aluminum Foil Metal Detector for Food Packaging Line Industry Applications

The DD-220 Series is engineered specifically for aluminum-foil packaging, metallized-film bags, retort pouches, and high-product-effect foods. With a dedicated high-frequency detection mode, it solves inspection challenges traditional metal detectors cannot handle.

Ideal for chocolate bars, baked goods, pastries, coated snacks, energy bars, roasted nuts, and mixed seeds packaged in aluminum foil or metallized-film wrappers.

Typical applications include:

Final inspection on horizontal flow-wrappers or pillow-pack machines

Detection of blade fragments or wire breakage after cutting processes

Stability against product effects caused by oil, cocoa, moisture, and sticky textures

This industry relies heavily on foil or metalized packaging, making high-frequency foil detection essential.

Designed for ready meals, microwaveable trays, MAP preserved foods, retort pouches, and aluminum-foil trays commonly used in modern prepared-food operations.

Use cases:

Post-sealing inspection for instant meals and ready-to-heat dishes

Metal contamination monitoring in foil trays or laminated pouches

Production lines handling high-salt or high-moisture products with strong product effect

A critical solution for high-throughput food factories demanding both speed and accuracy.

Suitable for smoked seafood packs, marinated meat pouches, frozen fillets in metalized films, processed meat trays, and vacuum-sealed foil-layer packaging.

Advantages in this industry:

High-frequency penetration through multi-layer barrier films

Compensation for salt, water content, and temperature variations

Reliable detection performance even on cold or frozen products

This makes DD-220 a strong choice for seafood and meat packers where conventional detectors fail.

Applicable to facial masks in aluminum-foil bags, cosmetic sachets (cream, gel, lotion), personal care wipes, and foil-layered sample packages.

Typical benefits:

Stable inspection for viscous, oil-based cosmetic products

Detection through metallic foil pouches without false-triggering

Compact integration with high-speed filling and sealing lines

A reliable solution for contamination control in personal care manufacturing.

Aluminum Foil Metal Detector for Food Packaging Line Case Studies

Why Choose Us for Aluminum Foil Metal Detection Solutions?

Expertise in Foil-Package Metal Detection

We specialize in solving the challenges conventional metal detectors cannot handle—especially aluminum-foil and metallized-film packaging inspection.

Industry-Proven Across Multiple Sectors

Our solutions are widely applied in:

·Bakery Confectionery, Snacks and Nuts

·Convenience Foods and Takeaways

·Fish, Seafood and Meat

·Personal Care and Cosmetics Products

Customers feel confident seeing their specific industry addressed.

Advanced Foil-Mode, Multi-Frequency DSP Technology

Ensures stable detection through complex packaging materials and reduces false rejects.

Customizable, Fast Delivery & Worldwide Support

·Non-standard sizes available

·Packaging film–specific tuning

·Remote technical support

·Fast15-20 day production

Complete Quality Control Ecosystem

·We also provide:

Offering a full, integrated quality control solution.

DD-220 Aluminum Foil Metal Detector Features & Performance

High-Frequency Foil Package Detection Technology

The DD-220 Series uses a dedicated high-frequency detection channel designed to penetrate aluminum-foil and metallized packaging materials. It effectively detects:

·Ferrous metals

·Non-ferrous metal

·Stainless steel particles

This solves the most challenging detection scenario: metal contaminants inside foil-wrapped products.

Advanced Multi-Spectrum DSP Processing

The system uses multi-spectrum digital signal processing to suppress product effect from:

Oil, fat, sugar

Moisture and salt content

Temperature changes

High-density or sticky foods

Result: stable detection, minimized false rejects, and repeatable quality control.

Compact Conveyor Structure Optimized for Packaging Lines

Designed for pillow packaging lines, rotary packing machines, and flow-wrappers

·Easy mechanical integration with existing conveyors

·Multiple rejection devices available: air blast, swing arm, drop-gate, retracting belt

·Ensures smooth, high-speed inline inspection.

Smart Auto-Learning & Multi-Product Memory

·One-click auto-tuning for each product

·Stores 100+ product presets

·Fast switching for multi-SKU production environments

·Improves efficiency in factories with frequent product changes.

Hygienic Stainless-Steel Construction

·Full 304/316 stainless-steel structure

·IP65 optional washdown design

·Suitable for wet, oily, or cleaning-intensive food environments

Aluminum Foil Metal Detector Installation & Integration Guide

Placement on the Packaging Line

·Best positioned right after sealing (post-pack inspection)

·Keep conveyor speed stable

·Avoid metal interference near the aperture

Foil-Mode Calibration

·Activate the foil-mode high-frequency channel

·Perform “Product Learning” for each packaging film type

·Retort products should be tested after cooling for optimal accuracy

Reject System Configuration

Choose according to package weight and format:

·Air jet for light pillow bags

·Swing arm for trays or heavier packs

·Drop-gate for sachets or pouches

·Ensure rejected items fall into a secured reject bin.

Routine Test Procedures

·Daily verification with Fe / Non-Fe / SUS test pieces

·Keep belt, rollers, and sensors clean

·Confirm reject bin lock and capacity

Aluminum Foil Metal Detector for Food Packaging Line FAQs

Q1: Can the DD-220 detect metals inside aluminum-foil sealed bags?

A: Yes. It uses a specialized high-frequency channel designed for aluminum-foil and metallized-film packaging.

Q2: What types of metals can it detect?

A: Fe, Non-Fe, and stainless steel (SUS304/316) depending on packaging structure and product effect.

Q3: Can it work with high-speed pillow packing machines?

A: Absolutely. The compact design and fast-response DSP system make it suitable for fast-moving packaging lines.

Q4: Is it suitable for retort pouches and microwaveable packaging?

A: Yes. It is specifically designed for these types of foil-layered packages.

Q5: Can I connect this system to MES / ERP?

A: Yes. RS485, Modbus, and Ethernet communication modules are optional.

Review

- Loading...

Related Products

Please Contact Our Specialists at Any Time

- ASK SameGram

- Mobile Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions