Dual-Frequency Conveyor Metal Detector DD-390 Series

Customizable metal detector for conveyor belt with dual frequency, high sensitivity, and strong anti-interference.

Detail Information

Detail Information

Dual-Frequency Conveyor Metal Detector DD-390 Series

Introduction

The DD-390 Series Dual-Frequency Conveyor Metal Detector is engineered for production lines that require stable, high-precision contaminant detection. Built with advanced digital technology and imported components, it delivers strong anti-interference performance and consistent sensitivity across a wide range of products. The system supports multiple frequencies, intelligent learning, and memory functions to reduce product-effect issues—ideal for high-moisture, high-salt, or oily items.

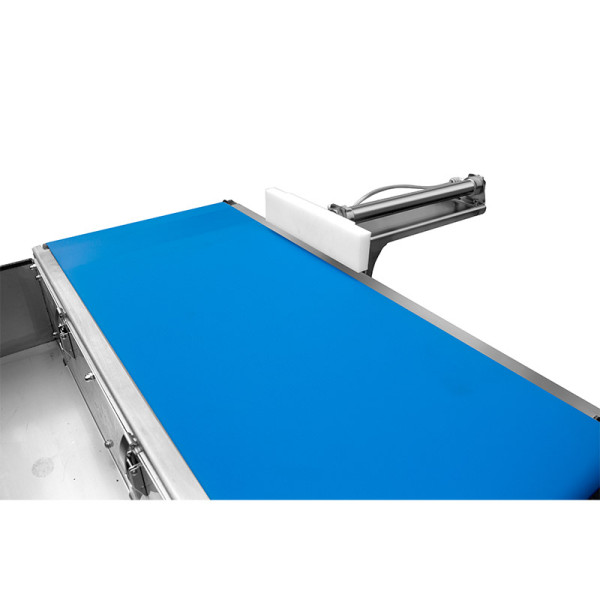

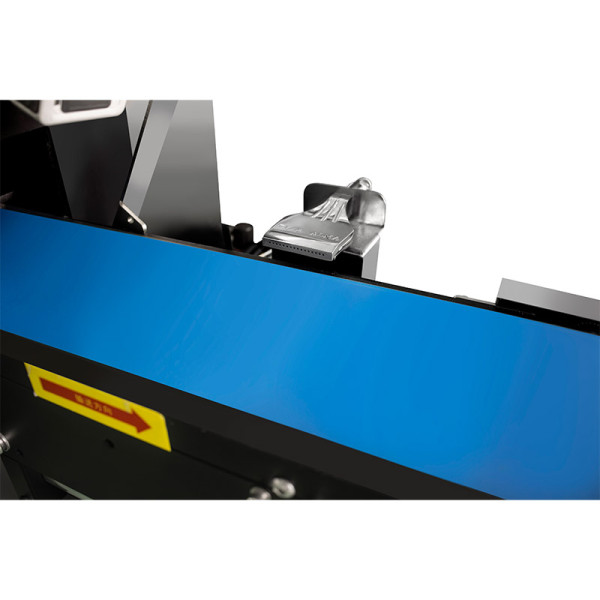

Its modular design allows easy cleaning and maintenance, while adjustable conveyor speeds (1–1000 m/min) make it suitable for both light and heavy packages. The DD-390 Series can be paired with air blast, pusher, or flapper rejectors and customized conveyor setups, offering a reliable solution for food metal detectors and metal detector conveyor belt applications in modern processing plants.

Dual-Frequency Conveyor Metal Detector DD-390 Series

Features

Dual-Frequency Conveyor Metal Detector DD-390 Series

Technical Parameters

| Product model | DD-390 (4012) | |

| External dimensions | 1350×802×950(L×W×H) customizable | |

| Effective detection channel | W 400 mm*H 120 mm | |

| Belt width | 350mm | |

Sensitivity (empty belt surface) | FE(Φ0.8mm),NON-FE(Φ1.2mm),SUS316(1.5Φmm) | |

Production speed | 1~1000m/min,fixed speed 25/min | |

Operation indication method | Flat touch buttons | |

Frame height | 700±50mm | |

Conveyor belt material | Food grade PU belt | |

Structure | SUS304,Comply with HACCP, GMP, FDA, CAS and other standards | |

Protection | IP 66 (probe) Others are IP54, optional | |

Relative humidity | 20 - 80%, non-condensing | |

Power supply | AC220V±10%, single phase, grounded; 47 Hz to 65 Hz, 100 W (max) | |

Operating temperature | Ambient temperature -10° to 40°C (14° to 104°F);Product temperature in well -10° to 55°C (14° to 131°F)。 | |

Language | English, Spanish, French, German, Italian, Chinese, Czech, Russian, Polish, Thai, Korean, Brazilian, Portuguese | |

Output type | 6 relay outputs; Relays: 250 volt AC 2 amp (max); 50 volt DC 1 amp (max) | |

Output allocation | Reject 1, Reject 2, Fault, Alarm, Warning, QA Light | |

Available Rejection Systems for Dual-Frequency Conveyor Metal Detector DD-390 Series

Up and Out Rejector for checkweigher and metal detector systems — stable, gentle, and precise for soft or thick products.

Fast swing arm works with checkweigher or metal detector systems to remove defective boxes and bags up to 1 kg.

Samegram’s Belt Drop rejector is a high speed rejector using pneumatic lift rods to gently remove thin bags and flat products.

The heavy-duty pusher rejector pair with checkweigher systems to deliver accurate, mid-speed removal of heavy, boxed items.

Air Jet Rejectors use powerful air bursts to remove lightweight or low-density items. Ideal for fast-moving lines.

File Downloads

For more product related parameter files, please contact us.

Dual-Frequency Conveyor Metal Detector DD-390 Series Applications

Review

- Loading...

Related Products

Please Contact Our Specialists at Any Time

- ASK SameGram

- Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions