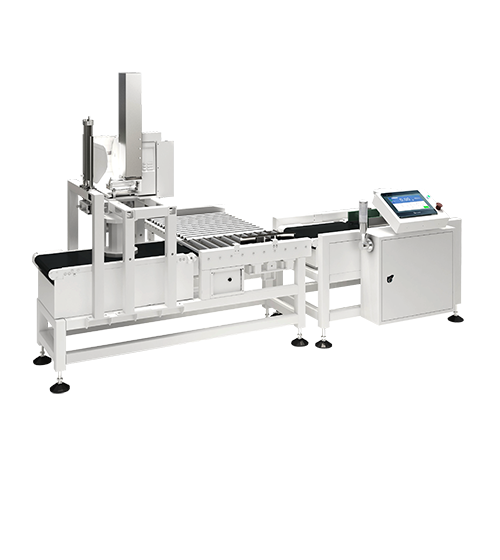

Checkweigher Combination System — A fully automated solution for checkweigher, detection, and label printing

The modular checkweighing system can be equipped with modules such as metal detection, real-time printing, automatic labeling, or barcode scanning to establish industrial applications that can accurately detect and trace.

- Introduce

- Featured

- Products

- Support

- Cases

- FAQ

- Blog

Checkweigher Combination System

- Real-time sync between label and weight data

- Touchscreen interface with multi-language support

- Food-grade stainless steel with hygienic design

- Supports Ethernet/IP, Modbus, Profinet integration

- Washdown-ready for dusty or wet environments

- High-speed checkweighing ensures minimal weight error

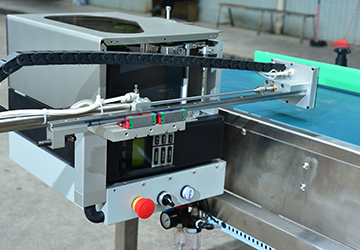

Multi-Function Integration

Combine weighing with labeling, metal detection, or inkjet printing to streamline packaging and compliance processes.

Modular Design

Flexible layout adapts to specific space, speed, and inspection requirements across industries and product types.

Space-Saving Structure

One system replaces three, reducing footprint and simplifying line layout for limited factory space.

Easy System Integration

Seamlessly connects with MES/ERP or other factory control systems to enable smart production and data traceability.

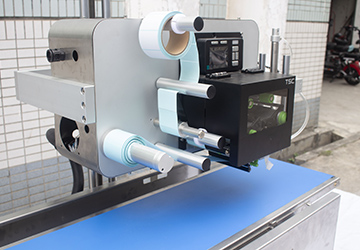

Print+Verify+Weigh

Real-time printing with barcode and QR code validation to ensure label accuracy, regulatory compliance, and export readiness.

Flexible Configurations

Supports label-only, label + scan, or weigh-price labeler setups to match specific production needs and budgets.

Compact, Modular Design

Space-saving structure fits into limited layouts; modular build allows upgrades like vision check, checkweighing, or scan-verification.

Real-Time Traceability

Links each label to product data, enabling full traceability across MES/ERP systems for audits, recalls, and supply chain transparency.

Checkweigher combination system related products

- Advanced Checkweigher with Labeller Combination System SCL-10060L50

SCL-10060L50 is an automatic weigh price labeler with scanning, weighing scale label printing, and template customization. It integrates seamlessly with weighing labelling and scanning software for industrial use.

- Weighting range

- 10g-50kg

- Weighting accuracy

- ±0.5-2g

- Labeling speed

- 15-25pcs/min

Checkweigher with Labeller Combination System SCL-7035L5SCL-7035L5 is a weighing and labeling automation solution that integrates a weigh price labeler and printer. It leads the automatic weigh price labelling machine market with compact design and precise performance.

- Weighting range

- 1-5000g

- Weighting accuracy

- ±0.5-2g

- Belt speed

- 15-50pcs/min

End of Line Checkweigher with Labeller Combination System SCL-8050L30SCL-8050L30 is an advanced automatic price weigh label machine with dynamic weighing, label editing, and MES/ERP integration. It supports flexible weigh price labeling across multiple production lines.

- Weighting range

- 10-30kg

- Weighting accuracy

- ±0.5-2g

- Labeling speed

- 15pcs/min

Checkweigher with Inkjet Printer Combination System SCISCI Automatic Inkjet Checkweigher integrates industrial inkjet printer for real-time inkjet printing. Accurate weighing and inkjet print in one printer inkjet system.

- Checkweigher with Metal Detector Combination System SCM-4530L2

SCM-4530L2 is a checkweigher metal detector combination for food processing. It integrates metal detection and weight control in one unit, ideal for checkweighers with metal detector needs on compact lines.

- Weighting range

- 1-2000g

- Weighting accuracy

- ±0.3-1g

- Belt speed

- 5-28m/min

- Instant Automatic Labeler Machine SL

SL is an automatic labeling machine for bottles and boxes. This automatic label machine supports fast, precise labeling. Ideal automatic labeling machine for bottles and automatic box labeling machine.

- Labeling speed

- 20-40p/min

- Labeling accuracy

- ±2-20mm

- Labeling part

- Flat top, optional sides

Automatic Labeler Machine with Weighing and Vision System SL-VThe SL-V is a label weighing scale system that integrates custom printed weigh scale labels with vision-guided labeling and real-time weight binding. A smart weigh price labeller ideal for post-packaging inspection.

Three-Axis Automatic Labeler Machine SL3SL3 is a three-axis automatic label applicator machine designed for space-limited factories. It works as an automatic bottle labeling machine, jar labeling machine, or wire labeling machine with flexible product switching.

Checkweigher combination system Selection & Comparison Guide

| Model/System | Function | Accuracy | Expandable Modules | Applications | Features | |

|---|---|---|---|---|---|---|

| SCL-7035L5 | Weighing + Labeling | ±0.5-2g | Scan, inkjet print, rejection | Prepacked foods, deli items, and small retail packages requiring inline weighing and labeling | Integrated weighing and labeling for products ≤ 5 kg, ensuring accurate labeling without slowing small-package lines. |

| SCL-8050L30 | Weighing + labeling | ±5-30g | scanning,rejection | End-of-line weighing and side labeling for cartons and boxes in food, beverage, and logistics packaging | Integrated carton weighing and side labeling for products ≤ 30 kg, suitable for medium-to-heavy packages on compact lines |

| SCL-10060L50 | Scanning,Weighing and Labeling | ±10-30g | rejection | Inline scanning, weighing, and labeling for products such as lacquered wire, coils, or traceable packaged items | Integrated scan‑weigh‑label‑re‑scan process for accurate traceability; suitable for products up to 50 kg |

| SCI-4523L3 | Weighing+inkjet printing | ±0.5-±1g | Scanning,Labeling,rejection | Inline weighing and coding for flat, lightweight products (books, cards, promotional items) | Integrated weighing and inkjet coding with traceability |

| SCM-4530L2 | Weighing + Metal Detection + rejection | ±0.3-1g | \ | Food, pharmaceutical, health supplement, and hygiene-sensitive products | Space-saving dual inspection system with synchronized weighing and metal detection |

| SL-V | Weighing + labeling | ±10mm | Scanning | Weighing and automatic labeling of various products across industries | Vision-guided labeling with integrated weighing for precise placement |

| SL3 | labeling | ±5mm | Weighing,Scanning | Automatic labeling for food, cosmetics, and small consumer goods production lines. | Compact, space-saving design with flexible product changeover, suitable for multiple product formats |

| SL | labeling | ±2-20mm | Weighing,Scanning | Automated labeling for boxes and flat surfaces in food, logistics, and retail packaging lines | Fully automated print‑and‑apply with integrated control, suitable standalone or for integration with weighing systems |

Get free

Checkweigher Combination System and Labeling System Selection Guide

- Recommendations for weight check and labeling in different industries

- Key considerations before automation upgrade

- ROI analysis case of high-precision weight check system

Support

One-Stop Service

Customized solutions

Integrated checkweigher, metal detector, and labeling system solutions tailored to streamline quality control workflows.

Installation, commissioning, and diagnosis

Online system commissioning with multi-module diagnostics to maintain continuous production flow.

Professional certification and technical support

Remote expertise ensuring smooth integration, data synchronization, and regulatory compliance.

Training and equipment maintenance

Virtual training covering combined system operations, software integration, and maintenance best practices.

Case studies of checkweighers with automatic label printing function

- Industry:

- Fresh vegetable packaging

- Equipment:

- Integrated checkweigher with labeling system

- Country:

- Near Ho Chi Minh City, Vietnam

Case studies of checkweighers with metal detectors

- Industry:

- Pharmaceutical manufacturing

- Equipment:

- SCM-4530L2 metal detector & checkweigher combo

- Country:

- Osaka, Japan

faq

Frequently Asked Questions

- Q: Can you supply combined metal detector and checkweigher systems?The SameGram SCM-4530L2 checkweigher and metal detector combination system provides reliable weight control and metal detection in a single, compact unit, featuring a space-saving design and easy operation for food production lines.A:Yes. SameGram provides advanced checkweigher and metal detector combination systems, including the SCM-4530L2 model. This integrated solution performs accurate weight control and metal detection in one compact unit, helping manufacturers reduce footprint, ensure product quality, and streamline compliance with food safety standards. With a space-saving design and easy operation, it is ideal for modern food production lines.📝Learn More about Checkweigher with Metal Detector Combination System

- Q: Are SameGram metal detectors and checkweighers compliant with food safety standards?SameGram inspection systems meet global food safety standards including HACCP, GFSI, BRC, and IFS, with hygienic design and full audit traceability.A:Yes. SameGram inspection systems are designed with hygienic stainless steel construction and support compliance with international food safety frameworks, such as HACCP, GFSI, BRC, and IFS. They provide traceability and audit records to help food manufacturers meet strict quality and regulatory requirements. For specific certificates, please get in touch with SameGram directly.

- Q: How does SameGram customize solutions for different production lines and industries?SameGram customizes weighing and inspection systems to fit different industries and production lines, ensuring efficiency, compliance, and flexibility.A:SameGram tailors its checkweighers, metal detectors, labeling machines, and combination systems to meet the unique needs of each production line and industry. For the food, pharmaceutical, cosmetics, and logistics sectors, our engineering team adapts product size ranges, conveyor speeds, hygiene levels, and integration requirements. By aligning equipment design with specific regulatory standards and production goals, SameGram delivers efficient, compliant, and industry-ready inspection solutions.

- Q: Can I test my products on a checkweigher or metal detector before purchase?We offer free sample testing services to help customers verify equipment performance and compatibility before purchase, ensuring the best solution.A:Yes. Our machines can provide free testing for samples you send to us. Simply ship your samples to our facility, and we will conduct tests based on your product specifications. You will receive a detailed testing video, data report, and our recommended optimal solution. This helps you confirm equipment compatibility and performance before purchase, reducing procurement risks.

- Q: What is the weighing accuracy of SameGram machines?SameGram checkweighers provide high-precision weighing, with accuracy ranging from ±0.02 g to ±10 g, depending on model and load — ensuring reliable performance for both light and heavy products.

A:

SameGram checkweighers offer high-precision performance with weighing accuracy ranging from ±0.02 g to ±10 g, depending on the model and product weight. For example, our SC1-C-3523L1 model delivers up to ±0.02 g precision for small items, while heavy-duty mo±3–10 g accuracy for loads up to 30 kg.

- Q: What's your MOQ for your products?SameGram accepts trial orders with no MOQ—1 unit is welcome.

A:

SameGram has no strict MOQ requirement. We welcome trial orders starting from just 1 unit, especially for first-time customers who want to test product performance before scaling up.

Insight into Checkweigher Combination System

- Checkweigher with Metal Detector for Beverage Quality ControlDiscover SameGram's advanced checkweigher with metal detector for beverage production. Ensure accurate weights, detect contaminants, and boost efficiency in bottling lines. Explore benefits and custom systems today.More

- High-Speed Weigh Price Labellers for Snack Food Production | SameGramDiscover high-speed weigh price labellers for efficient snack food packaging. Integrate checkweighers, automatic labeling, and metal detection for precision, compliance, and cost savings. Explore SameGram's customizable systems today.More

- Weigh Price Labellers for Meat & Cheese Packaging: Efficient SolutionsDiscover how SameGram's weigh price labellers streamline meat and cheese packaging with accurate weighing, pricing, and labeling. Boost efficiency, ensure compliance, and reduce costs in your food processing line.More

- How to Choose the Right Weigh Price Labeller for Your Production LineExpert guide to picking a weigh-price labeller that cuts waste, hits FDA/HACCP compliance & runs 60 ppm. Compare specs, price & ROI—free checklist.More

Contact Us

Thank you for your interest in SameGram. Please fill in the project information on the right so we can provide you with better and more comprehensive services.Get solutions

Get free quotes

Quick response

- ISO/MID certified

- 100+ customers trust

- 1-on-1 engineer support

Real-time Label Printing and Labeling Equipment Selection Registration Form

- Labeling technical parameters

- Mobile Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions