How Dynamic Checkweighers Boost Efficiency in Fruit Processing Plants

In the fast-paced world of fruit processing, where freshness, quality, and speed are everything, maintaining efficiency without sacrificing accuracy is a constant challenge. That's where dynamic checkweighers come in. These advanced systems ensure every package meets exact weight specifications, helping plants avoid costly errors and comply with strict food safety regulations. As a leading provider of industrial weighing solutions, SameGram has been at the forefront of this technology for over 16 years. Our high-precision and ultra-fast checkweighers are designed specifically for demanding environments like fruit packing lines, drawing on our expertise in modular, customizable automation. To learn more about our company and how we can tailor solutions to your needs, visit our About Us Page.

The Role of Checkweighers in Modern Fruit Factories

Dynamic checkweighers are essential tools in today's fruit processing plants. They perform real-time weight verification as products move along the production line, ensuring each package—whether it's a punnet of berries or a bag of apples—conforms to design specifications and regulatory standards. This not only guarantees product consistency but also helps maintain food safety by preventing underfilled or overfilled items from reaching consumers.

At SameGram, our dynamic checkweigher systems, like the Dynamic Checkweigher Inline Checkweighing Systems SC3-8050L30, handle weighing ranges from 0.05-30kg with accuracies as fine as ±3-10g, making them ideal for fruit applications. These in-motion checkweighers integrate seamlessly into existing lines, providing instant feedback to operators and reducing manual interventions. For fruit processors dealing with variable product sizes, such as irregular shapes in vegetables or delicate berries, this means fewer bottlenecks and smoother operations.

Reducing Waste and Overfilling in Fruit Packing

One of the biggest pain points in fruit packing is waste from inaccurate filling. Overfilling leads to unnecessary product giveaway, while underfilling can result in customer complaints or regulatory fines. Dynamic checkweighers address this by automatically detecting deviations and triggering reject systems to remove non-compliant packages.

In practice, this can cut waste by up to 15% in processing lines, as seen in general food industry applications. For instance, in berry packing, where precise portioning is key, our high-speed dynamic checkweigher (up to 280 pieces per minute) ensures minimal overfill, saving resources and boosting profitability. By incorporating features like automatic rejection conveyors, SameGram's systems allow for quick corrections, turning potential losses into efficient recycling or repacking opportunities. If you're facing similar issues, explore our Checkweigher Product Details to see how we can help optimize your setup.

Real-World Efficiency Gains of Inline Checkweighers

Seeing dynamic checkweighers in action highlights their impact. In fruit processing, these systems have transformed operations by increasing throughput and reducing labor costs.

Case Study: Enhancing Berry Processing Lines

Consider a typical berry processing facility handling high volumes of delicate fruits like blueberries. By implementing a dynamic checkweigher system, the plant automated weight verification after packing, sorting out incorrect packages for manual adjustment. This led to a 30% productivity boost and significant waste reduction, as overweighed items were corrected rather than discarded. At SameGram, we've seen similar results in our installations, such as a prepared food factory where our combination system improved labeling accuracy to 99.8% and cut labor by 40%. Our modular designs, compliant with HACCP and GFSI standards, ensure such gains are achievable in fruit lines too.

Click here for more Industry Checkweigher Specific Success Stories, and our Factory Capabilities, where we detail how our 4000+ m² manufacturing base supports custom solutions for over 5,000 clients worldwide.

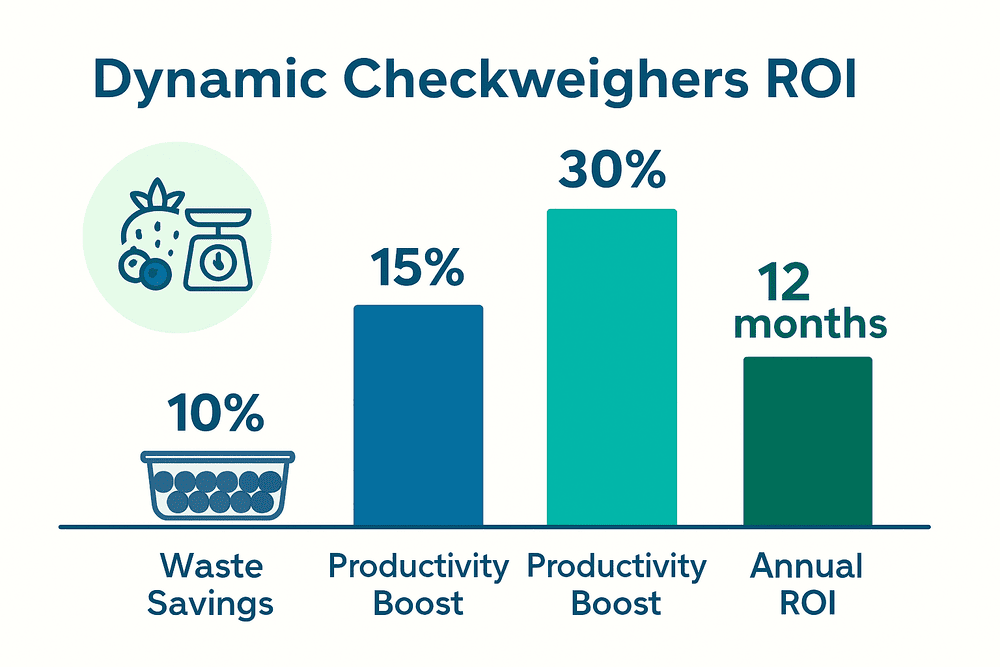

ROI Calculator Example

Calculating the return on investment (ROI) for a dynamic checkweigher is straightforward. Suppose your plant processes 10,000 fruit packages daily, with a 2% overfill rate costing $0.50 per package in excess product. That's $100 in daily losses, or $36,500 annually. Installing a high-accuracy checkweigher, like SameGram's High Speed Dynamic Checkweigher for Flat Products SC1-5040L5 (accuracy ±0.5-3g, belt speed up to 5-90m/min), could reduce overfill to 0.5%, saving $27,375 yearly.

Factor in reduced downtime and compliance fines, and ROI can be realized in under a year. Use this simple formula: Annual Savings / System Cost = ROI Period. For personalized estimates, contact us via our Checkweigher Products List to discuss your setup.

Technical Features for High-Speed Checkweigher System for Fruit Lines

Fruit lines demand equipment that keeps up with rapid production while maintaining precision and cleanliness.

Speed Rates, Accuracy Levels, and Hygiene Standards

SameGram's dynamic checkweighers excel here, with belt speeds up to 120m/min and accuracies from ±0.02g for small packages to ±30g for heavier loads. For fruit, models like the Hygienic Food Checkweigher for Lightweight Packages SCF-4523L3 (1-3000g range, ±0.3-2g accuracy) are built for wet environments, featuring IP65/IP69K protection and stainless steel construction for easy washdown.

Hygiene is paramount—our systems use food-grade materials with no dead ends, ensuring compliance with BRC and IFS standards. This prevents contamination in moist fruit processing areas, while high-speed operation matches fast lines without compromising accuracy.

Compact automatic weigh price labeller for food packaging, offering real-time weighing and label printing.

Categories: Checkweigher Combination System

Trademark/Brand: SameGram

Model: SCL-7035L5

Weighting range: 1-5000g

Belt speed: 15-50pcs/min

Weighting accuracy: ±0.5-2g

Weighting section size: L 700mm*W 300mm

Applicable product size: L≤500mm; W≤300mm

Labeling accuracy: ±5+30mm

Integrating High Speed Checkweighers with Sorting Machines

Dynamic checkweighers shine when integrated with sorting systems. In fruit plants, combining them with weight sorters or metal detectors creates a seamless workflow. SameGram's combination systems merge checkweighing with detection (sensitivity: Fe 0.3mm, SUS 0.6mm) in one unit, reducing footprint and boosting efficiency by 40% in some cases.

For vegetables and fruits, this means automatic routing of packages: proper weights proceed to labeling, while deviations go to adjustment stations. Our modular approach allows easy addition of barcode scanning or inkjet printing, supporting full traceability. If you need broader options, browse our Graded by Weight Solutions or Weighing,metal detecting and labeling Solutions Homepage.

Future Trends in AI-Enhanced Checkweighing

Looking ahead, AI is set to revolutionize checkweighing. SameGram is investing in AI-assisted inspection, where algorithms predict deviations and optimize lines in real-time. In fruit processing, this could mean adaptive sorting for variable produce, reducing waste further through predictive analytics.

Our Industry 4.0-ready systems already feature real-time data connectivity, paving the way for smarter factories. As regulations tighten, AI-enhanced dynamic checkweighers will ensure even greater compliance and efficiency. Ready to future-proof your plant? Reach out to SameGram for a free consultation and sample testing—we're here to elevate your operations.

Hot-Sale Checkweigher System

SCF-4523L3 is a hygienic checkweigher with high precision and hi speed checkweighing for food industry use,easy to integrate

Six-arm weight sorter ensures precise, hygienic food-grade sorting with waterproof protection for fish, poultry, and seafood.

SBW-2512B12 is a multi head combination weigher ideal for fast, precise dosing,also known as linear combination scale.

Compact automatic weigh price labeller for food packaging, offering real-time weighing and label printing.

Hi-speed automatic weigh price labeller with barcode verification, adaptive label control and ERP/MES integration for indutries