Instant Noodle Checkweigher Case: Production Efficiency Guide

In the fast-paced world of instant noodle manufacturing, maintaining consistent product weight is crucial for quality control, regulatory compliance, and customer satisfaction. Over or underfilled packages can lead to waste, rework, or even recalls, costing time and money. That's where a precise dynamic checkweigher comes in—a game-changer for production lines. At SameGram, we specialize in high-precision automatic checkweighers designed to integrate seamlessly into automated systems, ensuring every noodle pack meets exact specifications.

As a leading provider of industrial weighing solutions, SameGram has been at the forefront of innovation for years. Our dynamic checkweighers are engineered with cutting-edge technology to handle high-speed operations while delivering unmatched accuracy. Whether you're dealing with varying noodle flavors, portion sizes, or packaging formats, our systems help streamline your process. For more about our commitment to excellence, explore our company overview.

Role of High-Precision Dynamic Checkweigher in Instant Noodle Manufacturing

A food checkweigher is an essential tool in food processing, particularly for products like instant noodles where weight consistency directly impacts portion control and nutritional labeling. Unlike static scales, a high speed checkweigher operates in motion, weighing products as they move along the conveyor belt at high speeds. This allows for real-time monitoring without slowing down the line.

In instant noodle production, the process begins with raw materials being mixed, extruded, and cut into noodle strands. These are then fried or dried, seasoned, and finally packaged. The filling stage is where variability often creeps in—slight fluctuations in noodle density, seasoning amounts, or even humidity can affect the final weight. Our high accuracy checkweigher steps in post-filling to verify each package.

Key features of SameGram's dynamic checkweigher include:

● Ultra-Fast Processing: Capable of handling up to 300 packs per minute, ideal for high-volume instant noodle lines.

● Precision Weighing: Accuracy down to ±0.1g, ensuring compliance with standards like FDA or local food regulations.

● Robust Construction: IP65-rated for washdown environments, perfect for food factories where hygiene is paramount.

The Workflow: How Our Checkweigher System Integrates into Your Production Line

Integrating a high speed checkweigher into an instant noodle production line is straightforward and transformative. Here's a step-by-step breakdown of how it works, focusing on automation to minimize human intervention:

1. Product Filling: Noodles are portioned into cups, bags, or bowls using automated fillers. Variations can occur due to machine wear, ingredient inconsistencies, or environmental factors.

2. Conveyor Transfer: Filled packages move onto the industrial checkweigher conveyor. Our systems use flexible conveyor designs that adapt to different package sizes, from single-serve cups to family packs.

3. Dynamic Weighing: As packages pass over the weigh cell at speeds up to 1.5 m/s, the checkweigher instantly measures weight. If it's outside the preset tolerance (e.g., 70g ±1g for a standard noodle cup), it flags the issue.

4. Signal Output and Feedback: The industrial checkweigher sends a signal to the upstream filling system via PLC integration. For instance, if multiple packs are underweight, the system automatically adjusts the filler to dispense slightly more material. This closed-loop feedback ensures ongoing consistency.

5. Rejection and Sorting: Non-conforming packs are diverted using pneumatic rejectors or push arms, preventing them from reaching packaging. Compliant ones proceed to labeling and boxing.

The core advantage here is the adjustment of material usage. By providing real-time data, our inline checkweigher helps optimize filler settings, reducing overfill waste by up to 20% in typical setups. This not only maintains product uniformity but also boosts efficiency—lines run smoother with less downtime for manual checks.

One of our clients in the noodle industry reported a 15% increase in throughput after installing our high speed checkweigher. The automation aspect is key: it eliminates the need for operators to constantly monitor and tweak machines, freeing them for higher-value tasks. Plus, integration is plug-and-play with most PLC systems, often requiring just a few hours of setup.

For broader applications, see how our solutions extend to other industries in our Checkweigher application cases.

Advantages of Integrating SameGram's Dynamic Checkweigher

Switching to an automated checkweigher system offers tangible benefits, especially for instant noodle producers facing tight margins and high demands.

● Enhanced Accuracy and Compliance: With features like automatic calibration and data logging, our industrial checkweigher ensures every pack meets weight specs, helping avoid penalties from regulations.

● Cost Savings: By fine-tuning fill quantities, you minimize giveaway (excess product in packs). In noodle production, where ingredients like flour and seasonings add up, this can save thousands annually.

● Increased Efficiency: High-performance checkweigher system like ours handle diverse products without reconfiguration. For combo systems, we offer integrated metal detectors for added safety—detecting contaminants while weighing.

● Seamless Automation: Our checkweigher systems connect effortlessly to SCADA or ERP software, providing analytics on production trends. This data-driven approach helps predict maintenance needs and optimize runs.

● Hygiene and Durability: Designed for food environments, our washdown checkweighers resist moisture and cleaning agents, reducing contamination risks in noodle factories.

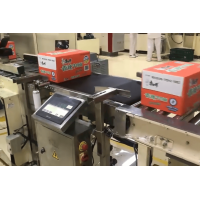

To see it in action, watch this video demonstration of our automatic checkweigher on a food line:

Instant Noodles Factory Automation: SameGram SC2-8040L15 Checkweigher in Action |Food Packaging Line

Dynamic Checkweigher for Instant Noodle Packets

Producers often struggle with inconsistent weights due to noodle expansion during drying or uneven seasoning distribution. Our precise food checkweigher addresses this by offering customizable rejection systems—e.g., multi-stage sorting for slight vs. major deviations.

For smaller operations, our compact models fit limited spaces without sacrificing speed. Larger lines benefit from our combination checkweigher with metal detector, ensuring no foreign objects slip through. Data from our systems can integrate with quality software to track batch performance, helping troubleshoot issues like filler blockages.

If you're expanding, consider our Checkweigher Combination System for all-in-one solutions.

Why Choose SameGram for Your Checkweigher Needs?

At SameGram, we're more than a supplier—we're partners in your success. Our state-of-the-art factory employs rigorous quality controls to produce reliable equipment. Learn more about our manufacturing process.

Ready to upgrade your line? Contact us today for a free consultation. Visit our full product lineup or homepage to explore how our industrial checkweighers, including automatic checkweigher systems and inline checkweighers, can transform your operations.

By investing in a high accuracy food checkweigher from SameGram, you're not just buying a machine—you're ensuring precision, efficiency, and peace of mind for your instant noodle production.

SameGram Hot-Sale Checkweigher

SCF-4523L3 is a hygienic food checkweigher with high precision and hi speed checkweighing for food industry use,easy to integrate

SC1-H-3512L1 is a high precision checkweigher designed for production line with high precision needs like pharmaceuticals etc.

Automatic Weigh Price Labeller with Customizable Labels & Non-Contact Labeling for Small Food Packages

SC-EP is a dynamic checkweigher for Ex zones, suitable for production lines with special requirements for explosion-proof

The SC3-10060L50 is an dynamic end of line checkweigher machine with built-in rejector, especially designed for large items.