Real-Time Tracking Weighing Technology in the Pharmaceutical Industry

Pharmaceuticals and nutraceuticals demand exceptional precision, hygiene, and traceability throughout production. With small dosages, high unit values, and strict regulations, even minor weight deviations or labeling errors can lead to compliance failures, recalls, or reputational risk.

From tablets and capsules to softgels, powders, and liquid supplements, the variety of packaging—blister packs, bottles, pouches, and vials—adds complexity to inspection and handling. Ensuring accurate fill weights, batch-level traceability, and contamination control is essential for maintaining quality, meeting GMP and international standards, and protecting consumer trust in highly regulated global markets.

difficulty

Industry Challenges

Strict Regulatory Compliance

GMP, FDA, and global standards demand error-free inspection, full traceability, and validated weight and labeling control.

ltra-Light Products, Ultra-High Precision

Tablets, capsules, and powders require extremely precise weighing—often within milligram tolerances—to avoid dosage errors.

High-Speed, High-Volume Production

Lines must maintain inspection accuracy at thousands of units per minute, without sacrificing throughput or performance.

Small Packaging, High Risk

Compact blister packs and vials make visual or manual inspection unreliable, increasing the risk of undetected defects.

Packaging Diversity and Complexity

Bottles, vials, pouches, and strips each demand unique inspection approaches, increasing complexity in automation and quality control.

Application Scenarios

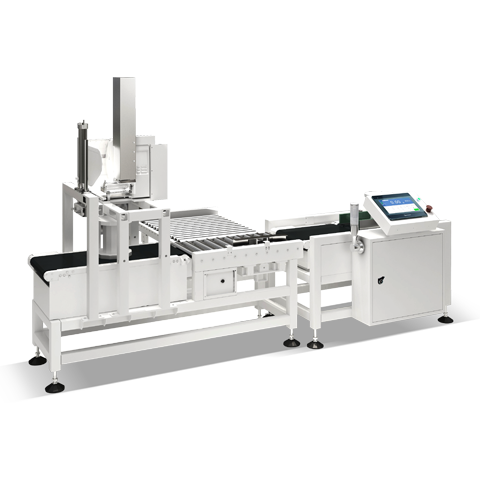

End-of-Line Packaging Automatic Weighing & Labeling

At the end of the packaging line, pharmaceuticals automatic checkweighers integrated with labeling machines ensure precise weight verification before storage or shipment. This solution guarantees accurate labeling, traceable production records, and reliable checkweighing solutions for pharma to prevent errors and minimize compliance risks.

Precise Quantity and Weight Control in Processing

In the processing of granules, powders, or small sachets, high-speed, high-precision pharmaceutical checkweighers safeguard production consistency. By instantly rejecting defective packs, they provide reliable checkweighers for drug manufacturing, preventing batch deviations and supporting strict regulatory compliance in pharma production.

Filling Accuracy & Efficiency for Small-Diameter Bottles

In pharmaceutical production, pharma checkweighing machines are essential for ensuring both accuracy and efficiency in liquid filling. For small-diameter containers such as vials and plastic bottles that are prone to tipping, specialized pharmaceutical checkweighers provide stable conveying and precise weight control. This guarantees consistent filling quality while improving overall line productivity.

Integrated with Transparent Film Packaging Machines

Pharma checkweighing equipment can be seamlessly integrated downstream of transparent film or shrink-wrapping machines. Each package is automatically verified for weight accuracy, and non-conforming items are removed, ensuring that only compliant products advance to the cartoning and distribution stage. This integration strengthens checkweighers for drug packaging performance.

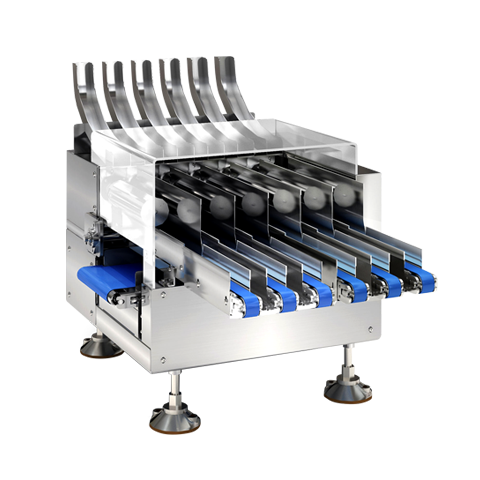

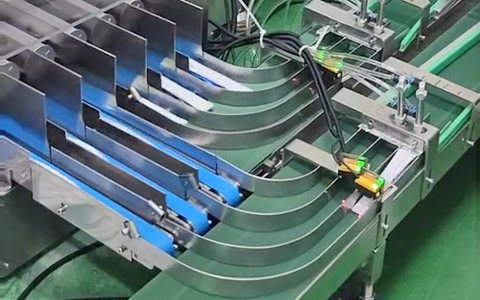

Multi-Lane Space-Saving Pharma Checkweighers

Pharmaceutical manufacturers need to ensure that each packaging unit on small strip or sachet production lines meets the required weight standards. The checkweigher automatically removes underweight or overweight packages, preventing missing or excessive filling.

Checkweigher with Metal Detector Combination System

During the packaging process, it is critical to verify both product weight and potential contamination. A combined medicine detector and checkweigher system provides dual protection by eliminating underweight/overweight packs and detecting metallic foreign bodies, delivering robust pharma checkweighing equipment for pharmaceutical quality assurance.

Recommended products

Boost Your Productivity with SameGram

Cooperation Cases

Pharmaceuticals And Health Products Industry Success Stories

Precision weighing boosts compliance and efficiency

"When we integrated SameGram's pharmaceutical checkweigher into our tablet packaging line, we achieved unmatched weight accuracy.

This ensured each blister pack met strict dosage requirements and minimized costly recalls. Our production speed increased without sacrificing compliance, giving our quality control team much-needed confidence."

Dr. Haruto Saito

Quality Assurance Manager, Tokyo, Japan

Seamless data traceability, easing audits

"SameGram’s pharmaceutical metal detector combined with checkweigher fully automated our inspection data logging.

Integration with our MES system means every batch is traceable, simplifying regulatory audits and supporting our EU GMP certification process. This upgrade transformed our digital quality management."

Sophie Müller

Production Director, Berlin, Germany

Reliable metal detection protects brand trust

"SameGram’s pharmaceutical metal detector identified and removed micro-metal contaminants in our liquid supplements production line.

Its high sensitivity and stable performance reduced false rejects and prevented expensive recalls. Protecting product safety is essential for maintaining our reputation in the global market."

David Park

Operations Manager, Seoul, South Korea

Free Sample Test

We offer free sample testing and demonstration setups customized to your product type and packaging format!

Why Partner with SameGram for Smart Manufacturing

From labor-intensive to data-driven

Real-time tracking of every gram

Seamless access to MES/ERP

Modular Scalable Remote Ready

Future Proof Architecture with Room to Grow

Remote Line Assessment and Custom Support

Get a Free Solution Plan

Contact our team of experts for:

- Free line evaluation

- Customized product testing

- Customized machine configuration

- Request a free consultation or Book a live demo

- ASK SameGram

- Mobile Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions