Home / All / Conveyor Metal Detector / Digital Conveyor Metal Detector for Food & Pharma Inspection DD-500 series

Digital Conveyor Metal Detector for Food & Pharma Inspection DD-500 series

DD-500 Series is an advanced conveyor belt metal detector using smart touch-screen control. Ideal for food production and other

Detail Information

Detail Information

Digital Conveyor Metal Detector for Food & Pharma Inspection DD-500 series

Introduction

The DD-500 Series is an intelligent conveyor metal detector designed for high-sensitivity inspection in food, pharmaceutical, textile, and chemical industries. Featuring a 7-inch touchscreen and one-touch auto-learning, it streamlines metal detection and improves production efficiency. This metal detector for food processing stores over 200 product profiles, logs operational data, and displays detection signals in real time. Its robust design ensures high stability, low interference, and IP65 protection, with customizable options for product size, weight, and production line integration. Ideal as a metal detector conveyor, the DD-500 supports compliance, reduces manual inspection, and guarantees precise, reliable detection in modern processing lines.

Digital Conveyor Metal Detector for Food & Pharma Inspection DD-500 series Features

Digital Conveyor Metal Detector for Food & Pharma Inspection DD-500 series

Technical Parameters

| Product model | Overall machine dimensions (mm) | Probe dimensions (mm) | Detection sensitivity (mm) | ||||||||

| H3 | H4 | L | W | W1 | W2 | H1 | H2 | FE | NO-FE | SUS | |

| 700 | 880 | 1200 | 650 | 300 | 250 | 110 | 80 | 0.5 | 0.8 | 1.0 | |

700 | 900 | 1200 | 650 | 300 | 250 | 130 | 100 | 0.6 | 0.8 | 1.2 | |

700 | 920 | 1200 | 650 | 300 | 250 | 150 | 120 | 0.8 | 1.0 | 1.5 | |

700 | 950 | 1200 | 650 | 300 | 250 | 180 | 150 | 1.0 | 1.2 | 2.0 | |

700 | 900 | 1330 | 750 | 400 | 350 | 130 | 100 | 0.6 | 1.0 | 2.0 | |

700 | 920 | 1330 | 750 | 400 | 350 | 150 | 120 | 0.8 | 1.2 | 1.5 | |

700 | 950 | 1330 | 750 | 400 | 350 | 180 | 150 | 1.0 | 1.5 | 2.0 | |

700 | 900 | 1330 | 850 | 500 | 450 | 130 | 100 | 0.8 | 1.2 | 2.0 | |

| 700 | 920 | 1330 | 850 | 500 | 450 | 150 | 120 | 1.0 | 1.5 | 2.3 | |

700 | 950 | 1330 | 850 | 500 | 450 | 180 | 150 | 1.2 | 2.0 | 2.5 | |

Maximum transportable weight | 0-25KG | ||||||||||

The conveying speed | 25m/m constant speed or custom speed adjustable | ||||||||||

power supply | AC220V±10% 50-60Hz, customizable voltage. | ||||||||||

Usage environment | Temperature -20℃ to 50℃, humidity below 90% | ||||||||||

Heavy-duty models | |||||||||||

Model specifications | Overall machine dimensions (mm) | Probe dimensions (mm) | Detection sensitivity (mm) | ||||||||

H3 | H4 | L | W | W1 | W2 | H1 | H2 | FE | NO-FE | SUS | |

5030 | 700 | 1100 | 1600 | 850 | 500 | 450 | 330 | 300 | 2.0 | 2.5 | 3.0 |

6030 | 400 | 800 | 1600 | 950 | 600 | 550 | 330 | 300 | 2.5 | 3.0 | 3.5 |

6035 | 400 | 850 | 1800 | 950 | 600 | 550 | 380 | 350 | 3.0 | 3.5 | 4.0 |

6040 | 400 | 900 | 1800 | 950 | 600 | 550 | 430 | 400 | 3.5 | 4.0 | 4.5 |

6050 | 400 | 950 | 1800 | 950 | 600 | 550 | 530 | 500 | 4.0 | 4.5 | 5.5 |

Maximum transportable weight | 25-200KG | ||||||||||

The conveying speed | 25m/m constant speed or custom speed adjustable | ||||||||||

power supply | AC220V±10% 50-60Hz, customizable voltage. | ||||||||||

Usage environment | Temperature 0℃~40℃, humidity below 80% | ||||||||||

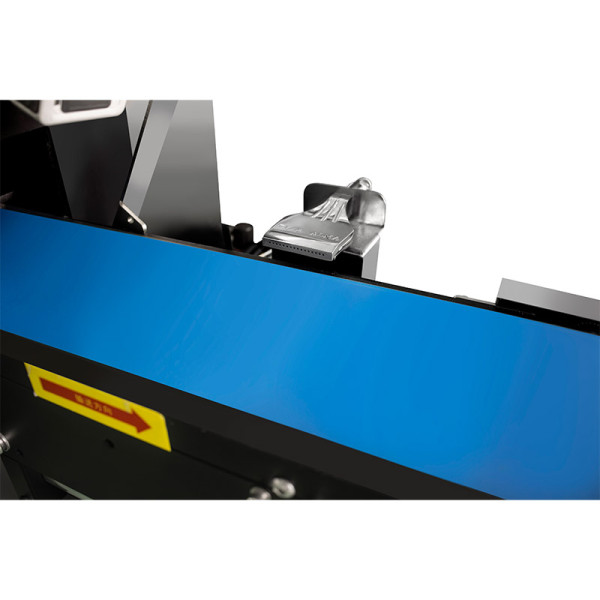

Available Rejection Systems for Digital Conveyor Metal Detector SCF-4523L3 DD-500 series

Up and Out Rejector for checkweigher and metal detector systems — stable, gentle, and precise for soft or thick products.

Fast swing arm works with checkweigher or metal detector systems to remove defective boxes and bags up to 1 kg.

Samegram’s Belt Drop rejector is a high speed rejector using pneumatic lift rods to gently remove thin bags and flat products.

The heavy-duty pusher rejector pair with checkweigher systems to deliver accurate, mid-speed removal of heavy, boxed items.

Air Jet Rejectors use powerful air bursts to remove lightweight or low-density items. Ideal for fast-moving lines.

File Downloads

For more product related parameter files, please contact us.

Why Choose Us for Digital Conveyor Metal Detection Systems?

16 Years of Industry Expertise

We specialize in food safety inspection, pharmaceuticals QC, and factory automation, serving clients in 50+ countries.

Strong R&D and Customization Capability

With advanced DSP algorithms and modular platform design, we tailor:

·Aperture sizes

·Conveyor materials

·Rejection units

·Communication protocols

Proven Performance Across Multiple Industries

Our systems run in leading factories across:

·Pharmaceuticals and Health Products

·Dairy Products and Eggs

·Fish, Seafood and Meat

·Metals, Plastics and Electronic Components

Fast Lead Times and Reliable Service

15-20 days delivery for standard models, lifetime technical support, and global remote assistance.

Complete Inspection Solutions

Beyond metal detectors, we offer:

Your one-stop partner for quality control and contamination detection.

Digital Conveyor Metal Detector for Food & Pharma Inspection Technical Features & Performance

High-Sensitivity Dual-Channel Metal Detection

The DD-500 Series adopts advanced digital DSP processing, delivering accurate identification of Fe, Non-Fe, and SUS304/316 contaminants with reduced signal drift and better long-term stability.

Enhanced Anti-Interference Architecture

·Multi-frequency adaptive scanning

·Auto balance correction

·Filtering of vibration and environmental noise

This ensures stable detection in facilities with motors, conveyors, or packaging machines operating nearby.

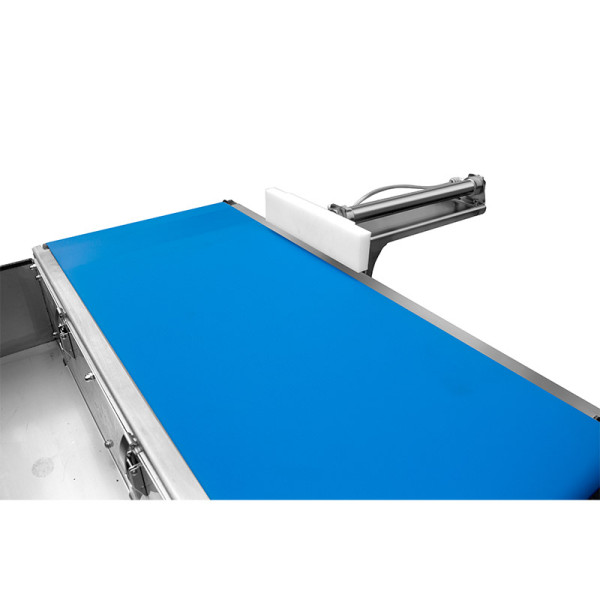

Wide Detection Window & Conveyor Options

Available in multiple aperture sizes and belt configurations, including:

·Flat PVC conveyor

·Modular belts

·Washdown stainless-steel conveyor

Engineered for integration into existing production lines.

Intelligent Product Learning Function

Automatically stores and optimizes product parameters such as density, temperature, and moisture levels — ideal for:

·Dairy (high product effect)

·Seafood (saltwater retention)

·Moist or metallic-packaged goods

DD-500 Digital Conveyor Metal Detection System Industry Applications

Our DD-500 Series Digital Conveyor Metal Detector delivers stable, high-sensitivity performance across multiple industries. By optimizing detection algorithms, coil stability, and anti-interference design, it ensures reliable contamination control in:

The metal detector provides ultra-stable sensitivity for tablets, capsules, powders, and packaged nutraceuticals, effectively identifying ferrous, non-ferrous, and stainless-steel contaminants.

Typical applications include:

·Inline inspection before blister packaging

·Final QC inspection for bottled supplements

·Detection of machine-generated metal dust in powder filling lines

It helps pharmaceutical plants meet CE and ISO compliance.

Highly suitable for cheese blocks, shredded cheese, butter sticks, yogurt packs, and liquid-filled pouches.

The DD-500 Series compensates for high moisture and temperature variations, reducing false rejects and ensuring stable performance even with high-product-effect dairy matrices.

Designed for fresh, frozen, chilled, or vacuum-packed proteins such as fish fillets, meat blocks, sausages, seafood trays, and marinated cuts.

The digital signal processing ensures reliable detection even when salt content, temperature, and product humidity fluctuate. Ideal for:

·Bone-in and bone-out lines

·Frozen seafood processing

·Protein packaging inspection before sealing

Beyond food, the system supports industrial QC for injection-molded parts, plastic granules, rubber materials, and lightweight electronics.

It helps detect metal impurities originating from molds, cutters, and recycling processes — lowering customer complaints and improving material purity.

Digital Conveyor Metal Detector for Food & Pharma Inspection Case Studies

Digital Conveyor Metal Detector DD-500 Installation & Integration

To ensure optimal performance of your DD-500 Series Digital Conveyor Metal Detector for Food & Pharma Inspection, we recommend the following installation practices:

Optimal Environment Setup

·Maintain a stable power supply and proper grounding

·Keep away from strong vibration or magnetic fields

·Avoid placing the machine next to metal structures that may affect coil balance

Conveyor Line Integration

·Keep feeding speed consistent

·Reserve space for rejection systems (air blow, pusher, flap, drop-gate)

·Ensure upstream and downstream conveyors are aligned to prevent product bouncing

Product Calibration

·Use “Product Learning” for all new products — especially:

·High-salt items (seafood, pickled foods)

·High-moisture dairy

·Metallic-film packaging

Routine Maintenance

·Clean conveyor belts regularly

·Inspect coils and rejector mechanisms

·Test sensitivity weekly using standard test pieces

Digital Conveyor Metal Detector for Food & Pharma Inspection FAQs

Q1: Can the DD-500 Series detect stainless steel in aluminum-foil packaging?

A: In foil-pack applications, select our X-ray inspection systems or Aluminum Foil Metal Detector DD-220 series. The DD-500 handles metallic packaging only if product effect is acceptable.

Q2: Does product temperature affect detection sensitivity?

A: Yes. Warm, moist, or salty products create product effect. Our DSP algorithm compensates for this, but calibration is recommended.

Q3: What rejection systems are available?

A: Air-blast, pusher, flipper, drop-box, and retract-belt options depending on product type and line speed.

Q4: Can it be connected to a PLC or factory MES system?

A: Yes. RS485 / Modbus / Ethernet options are available for data output and traceability.

Q5: Is this metal detector suitable for washdown environments?

A: Stainless-steel washdown models (IP66) are available for meat and seafood processing.

Review

- Loading...

Related Products

Please Contact Our Specialists at Any Time

- ASK SameGram

- Mobile Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions