Checkweighers for Metal, Plastic and Electronics Components

In high-tech manufacturing, precision is critical—especially when handling metal, plastic, and electronic components. As a checkweigher manufacturer, SameGram has long demonstrated how our checkweigher systems ensure that every screw, PCB, connector, battery cell, or injection-molded part meets exact weight specifications.These dynamic systems typically consist of infeed, weighing, and rejection modules, enabling 100% in-motion weight inspection—detecting underweight or overweight items and automatically rejecting non-compliant components.

What’s Being Weighed?

Metal parts: Screws, nuts & bolts, stamped brackets, die‑cast housings, machined shafts, metal shims, bearings

Plastic parts: Injection‑moulded housings, caps & closures, connectors, resin pellets, lightweight containers

Electronic components: PCBs & SMT reels, sensors, batteries, wire harnesses, micro‑motors, LED modules

difficulty

Industry Challenges

Micron‑level tolerances

Variations of ±0.02 g can trigger field failures or warranty claims.

Mixed SKU changeovers

Dozens of part numbers per shift require recipe recall in seconds.

Regulatory traceability

ISO 9001, IATF 16949 & IPC‑A‑610 demand full weight records.

Hidden defects

Missing screws in kits or incomplete PCB solder fill are only evident by weight.

Space‑constrained lines

High‑speed assembly cells leave <1 m for inline QA.

Application Scenarios

Fastener Verification on Bagging Lines

Injection-Molded Part Verification

SMT Reel and PCB Assembly Checks

Raw Material & Rework Sorting

Final Weighing Before Delivery

Recommended products

Boost Your Productivity with SameGram

Cooperation Cases

Weigh Smarter. Build Better — with SameGram

Plastic Components Manufacturer

Application: Raw Material & Rework Sorting with SC1‑C‑3523L1

“Since installing the SC1‑C‑3523L1 checkweigher, we’ve streamlined our rework flow. The system accurately separates off-spec parts before assembly, reducing manual labor and scrap by 30%—all without slowing down production.”

Key Benefits:

• Real‑time sorting of plastic injection scraps and regrind

• Automated traceability through our MES

• Improved first-pass yield from 92% → 98%

Metal Hardware Manufacturer

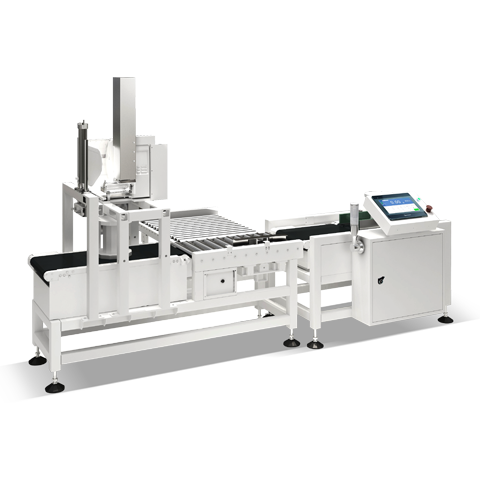

Application: Custom-designed high-speed dynamic checkweigher on compact conveyor

“We needed checkweighing for tiny metal components, in a constrained line layout. SameGram built a bespoke, compact checkweigher with a narrow belt and quick tare‑to‑gross switch. The equipment now runs at 200 ppm with ±0.1 g accuracy—exactly what our customers require.”

Key Benefits:

• Ultra-compact size fit into our tight workflow

• High throughput without weight drift

• Precise control: every batch now meets DIN tolerance spec

Injection-molded Components Producer

Application: Multi-function rejection & diversion checkweigher at end-of-line

“Our final QC line now features SameGram’s multifunction checkweigher that weights, rejects, and diverts parts before shipping. It’s reduced outward defects by 95% and has saved us from several potential non-compliance issues with overseas buyers.”

Key Benefits:

• 100% end‑of‑line inspection ensures no short‑shots ship

• Automatic rejection reduces QC manpower by 50%

• Custom diversion paths for non-conforming parts

Free Sample Test

We offer free sample testing and demonstration setups customized to your product type and packaging format!

Why Partner with SameGram for Smart Manufacturing

Minimize Manual Errors with Intelligent Weighing

Full Visibility, Gram by Gram

Seamless Integration with MES/ERP Systems

Scalable & Modular for Future Growth

Engineered for Long-Term Reliability

Remote Diagnosis & Expert Customization

Get a Free Solution Plan

Contact our team of experts for:

- Free line evaluation

- Customized product testing

- Customized machine configuration

- Request a free consultation or Book a live demo

- ASK SameGram

- Mobile Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions