Checkweighers for Dry Goods, Grains and Cereals Industry

Dried grains, pulses, and cereals—such as rice, wheat, corn, lentils, and oats—form the foundation of global food systems. These products move through high-volume, high-speed supply chains, where even small deviations in weight or safety standards can cause large-scale losses. Metal contamination, moisture variation, and improper packaging remain persistent risks across both domestic and export operations.

As food security, regulatory compliance, and cost control become increasingly intertwined, producers are under pressure to achieve consistent inspection standards at scale. Ensuring accuracy in every bag, batch, and shipment is not a luxury—it’s the baseline for operational stability and international competitiveness.

difficulty

Industry Challenges

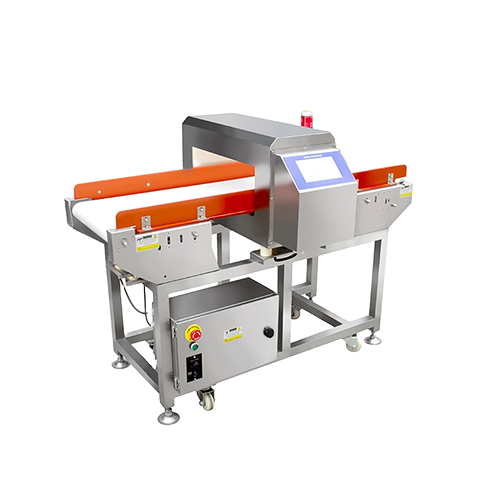

Foreign Metal Contamination from Agricultural Equipment

During harvesting, drying, and conveying, metallic impurities such as screws, blades, and iron filings are easily introduced, especially in raw bulk grains—posing serious food safety and export rejection risks.

Weight Variations Caused by Moisture Fluctuations

Ambient humidity and post-harvest drying inconsistencies can alter product density, making precise weight control difficult, especially for automated high-speed filling lines.

High-Speed Bagging with Irregular Packaging

Grain and pulse packaging varies widely—from woven sacks to vacuum pouches—leading to unstable positioning and poor label adhesion, often resulting in misapplied or unreadable labels.

Lack of Batch-Level Traceability in Bulk Processing

In many grain facilities, inspection results, weights, and rejection logs are not linked to specific lots—making recall, audit, and export documentation difficult or unreliable.

Sensitivity to Cross-Contamination in Shared Lines

Facilities often switch between grains (e.g., wheat → soybeans) on the same line. Without automated inspection and cleaning verification, allergens or unwanted materials may remain—violating compliance standards.

Application Scenarios

rice

wheat

corn

lentils

oats

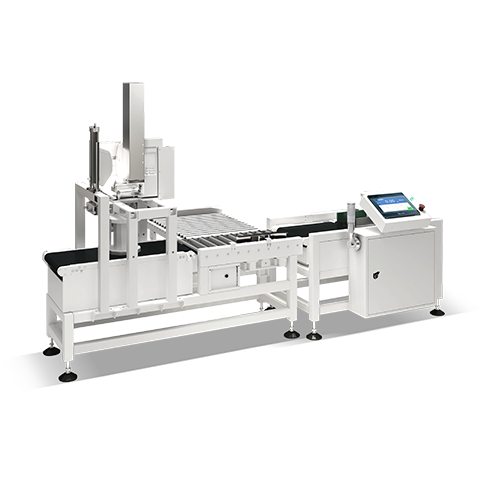

Recommended products

Boost Your Productivity with SameGram

Cooperation Cases

Dry Goods, Grains and Cereals Industry Success Stories

Bulk Grain Bag Precision Saves Costs

“When we upgraded our 50 kg quinoa and rice bags, Samegram’s food-grade bulk checkweigher ensured each sack met ±0.1% weight tolerance.

We cut overfill by 60%, saving over $100,000 annually. Our procurement team now plans inventory with full confidence.”

Carlos Méndez

Production Manager, Chile

Large-Scale Flour Bags – Reducing Overfill

“When we shifted to 25 kg wheat flour bags, Samegram installed a food-grade bulk checkweigher precise to ±0.05%, ensuring every sack met strict weight specs.

We cut overfill waste by 55%, saving over $120,000 annually and gaining precise inventory control.”

Li Wei

Plant Manager, China

Cereal Bar Packs – Guaranteeing Piece Count

“Our crunchy multi-grain bars are sold in multi-packs, where missing bars cost us in refunds and reputation. Samegram’s checkweigher for packaged food verifies total pack weight and identifies any missing items.

Since deployment, customer complaints have dropped by 90%, and repack labor is down by 50%.”

Anna Rossi

Quality Director, Italy

Free Sample Test

We offer free sample testing and demonstration setups customized to your product type and packaging format!

Why Partner with SameGram for Smart Manufacturing

From labor-intensive to data-driven

Real-time tracking of every gram

Seamless access to MES/ERP

Modular Scalable Remote Ready

Future Proof Architecture with Room to Grow

Remote Line Assessment and Custom Support

Get a Free Solution Plan

Contact our team of experts for:

- Free line evaluation

- Customized product testing

- Customized machine configuration

- Request a free consultation or Book a live demo

- ASK SameGram

- Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions