Checkweighers for Other Food and Beverage Industry

The “other food and beverage” category includes bottled drinks, canned beverages, sauces, powders, and aluminum-packaged snacks. With varied formats—PET, glass, foil trays, and sachets—producers face challenges in weight accuracy, sealing, and labeling. Aluminum packaging complicates metal detection, often causing false rejects and production delays.

High SKU turnover, seasonal runs, and strict export standards demand fast, flexible inspection with minimal waste. Ensuring consistent quality and compliance across such diverse lines is essential for maintaining efficiency and protecting brand reputation in competitive global markets.

difficulty

Industry Challenges

Overfill Waste

Uncontrolled filling in bottled sauces or drinks leads to product giveaway and higher unit costs.

Label Misalignment

Cans and bottles face frequent label errors due to curvature, condensation, or speed.

Powder Inconsistency

Lightweight powders shift during handling, making underfill or false rejects more likely.

Foil Detection Issues

Aluminum packaging often causes false alarms in metal detectors, delaying production.

SKU Switching Delays

High SKU turnover requires faster equipment changeovers to maintain line efficiency.

Application Scenarios

Bottled Beverages

Canned Drinks & Soups

Sauces & Condiments

Powdered Products

Foil-wrapped Snacks

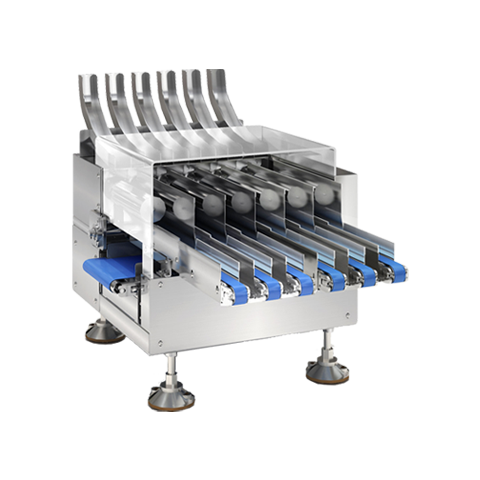

Recommended products

Boost Your Productivity with SameGram

Cooperation Cases

Other Food and Beverage Industry Success Stories

Precise portioning for premium bottled drinks

"We produce a range of functional beverages in PET and glass bottles. SameGram’s high-precision checkweigher made it easy to ensure accurate filling across all bottle sizes without slowing down our line.

Thanks to better portion control, we cut down giveaway by 12%, and our retailers reported fewer underweight complaints for export batches."

Carlos Mendes

Production Manager, Beverage Factory in São Paulo, Brazil

Reliable detection despite aluminum foil

"Our snack bars use foil wrapping, which used to cause false alarms on our old metal detectors.

SameGram’s system with dual-frequency tech greatly reduced false rejects and improved overall line efficiency.

Now we run faster without fearing metal detection errors, even during seasonal product switches."

Sarah Nolan

Plant Director, Snack Manufacturer in Dublin, Ireland

Seamless labeling for multi-SKU sauces

"We handle dozens of sauce types daily, each with different label and fill specs. SameGram’s integrated checkweigher and automatic labeling system helped us cut label mismatches by 95%.

The flexible switch between SKUs has made our changeover time 40% faster and export rejection rates nearly zero."

Takahiro Mori

Quality Supervisor, Condiments Producer in Osaka, Japan

Free Sample Test

We offer free sample testing and demonstration setups customized to your product type and packaging format!

Why Partner with SameGram for Smart Manufacturing

From labor-intensive to data-driven

Real-time tracking of every gram

Seamless access to MES/ERP

Modular Scalable Remote Ready

Future Proof Architecture with Room to Grow

Remote Line Assessment and Custom Support

Get a Free Solution Plan

Contact our team of experts for:

- Free line evaluation

- Customized product testing

- Customized machine configuration

- Request a free consultation or Book a live demo

- ASK SameGram

- Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions