Checkweighers for Confectionery, Snacks and Nuts

This category covers a wide range of high-frequency, net-weight sensitive products, typically including: Hard candies, soft chews, gummies, toffees, chocolate bars, filled chocolates, chewing gum, Potato chips, popcorn, tortilla chips, cereal bars, energy bars, crackers, extruded puffs, mixed snack packs, Roasted almonds, peanuts, cashews, pistachios, sugar-coated nuts, and dry nut-fruit blends (trail mix).

These products are often produced in high volumes with numerous SKUs, making them highly sensitive to weight compliance and labeling regulations.

difficulty

Food Processing Industry Challenges

Regulatory Net‑Weight Compliance

Under FDA 21 CFR 101.7 and NIST Handbook 133, every pack must meet labeled weight or risk fines and recalls.

SKU Proliferation & Pack

Size Variation – Retailers demand mini, single‑serve and family packs, driving frequent changeovers.

Sticky or Fragile Products

Gummies, chocolate‑covered nuts and wafer bars can stick, smear or crumble, complicating stable weighing.

Foreign‑Material & Allergen Risks

Metal fragments, shell pieces or hard plastic must be detected before shipping to protect consumers and brands.

High Line Speeds in Tight Spaces

Modern snack lines exceed 200 ppm, yet floor space is at a premium, especially in retrofit projects.

Application Scenarios

Snacks

Nuts

Energy and granola bars

Preserved Fruit

Confectionery

Recommended products

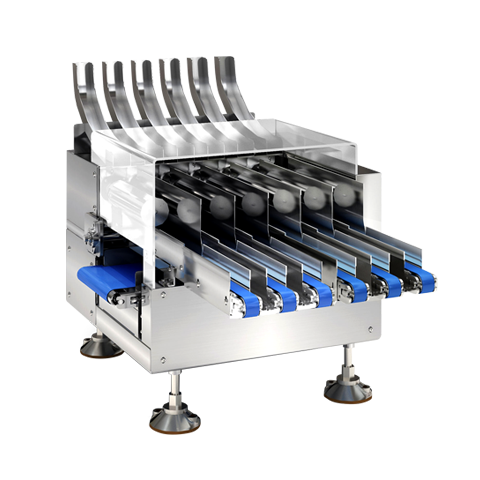

Boost Your Productivity with SameGram

Cooperation Cases

Food Processing Industry Success Stories

Gummy Producer

“We were constantly battling weight inconsistencies due to the stickiness of the product. Since installing the SCF-4523L3 checkweigher on our gummy bottling line, we've seen underweight rejects drop by over 90%. Even better, our overall line speed improved without any compromise in accuracy. It’s been a real game-changer for our throughput.”

A sticky‑gummy bottling line added SCF-4523L3 and cut underweight rejects by 92 % while gaining 18 % throughput.

Jason M

Production Manager

Pata Snack Nuts

“With the SCM-4530L2 integrated with a metal detector, we’ve finally reached the weight precision and food safety standards required by our top retail partners. Product giveaway has dropped dramatically—from 3 grams to less than 0.4 grams per tub—translating into substantial annual savings. This system has paid for itself in under 9 months.”

Switch to SCM-4530L2 and metal detection reduced giveaway from 3 g to < 0.4 g per tub, saving €110 k/year in raw nuts.

Luca

QA Director

European Chocolate-Bar Plant

“Replacing manual checkweighing with the SCP6 was one of the best upgrades we’ve made. Not only did we boost OEE by nearly 10%, but the system also enabled real-time feedback to our flow-wrapping line, reducing giveaway and stabilizing pack quality. Integration was smooth, and support from Samegram was excellent throughout.”

European Chocolate‑Bar Plant – Replacing manual check scales with SCP6 boosted OEE from 78 % to 87 % and enabled automatic feedback to flow‑wrappers.

Алекса́ндр

Senior Automation Engineer

Free Sample Test

We Offer Free Checkweigher Testing And Demo Setups Tailored To Your Product Characteristics And Packaging Line Requirements!

Why Partner with SameGram for Smart Manufacturing

From labor-intensive to data-driven

Real-time tracking of every gram

Seamless access to MES/ERP

Modular Scalable Remote Ready

Future Proof Architecture with Room to Grow

Remote Line Assessment and Custom Support

Get a Free Solution Plan

Contact our team of experts for:

- Free line evaluation

- Customized product testing

- Customized machine configuration

- Request a free consultation or Book a live demo

- ASK SameGram

- Mobile Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions