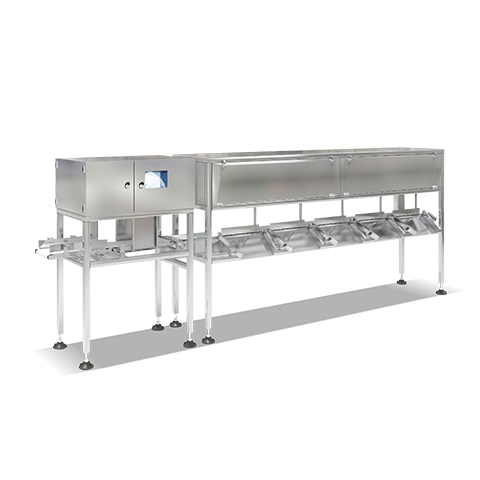

Intelligent Checkweigher for Fish, Seafood & Meat

In the production and processing of the fish, seafood and meat industry, there are many tough problems. These products are often irregular in shape, and some contain moisture and oil, which makes accurate weighing very difficult. Moreover, the industry has strict standards for product weight. Once unqualified products in terms of weight enter the market, it will not only affect the brand reputation, but also may lead to customer complaints and economic losses.

At the same time, food safety is the top priority in this industry. How to ensure the hygiene and safety of products during the weighing process and avoid problems such as cross-contamination is also a key issue that enterprises need to solve. In addition, the traditional manual weighing method is inefficient, difficult to meet the needs of large-scale production, and prone to human errors.

difficulty

Industry Challenges

Variable Weight and Size

Fish, shellfish, and poultry pieces vary widely, making consistent portioning and grading difficult.

Moisture and Surface Slipperiness

Wet and oily surfaces cause weighing inaccuracies and sorting errors on production lines.

Delicate Product Handling

Seafood and poultry require gentle sorting to prevent damage and maintain product integrity.

Metal Contamination Risk

Processing equipment may introduce metal fragments, threatening food safety and leading to recalls.

Regulatory Compliance and Traceability

Strict standards require accurate weight control and full traceability throughout processing and distribution.

Application Scenarios

Cold chain logistics centers

Conduct weight sampling inspection of fish, seafood and meat products when products are put into and out of the warehouse to ensure that there is no weight loss and other problems during transportation.

Food packaging enterprises

In the packaging process of fish, seafood and meat products, detect whether the weight of packaged products meets the standards to avoid customer complaints caused by insufficient or excessive weight.

Poultry processing plants

Detect and sort weights of whole/segmented poultry (chickens, ducks, geese; e.g., breasts, legs, wings). They distinguish weight grades, aid specification-based packaging/sales, ensure standardization, meet customer weight needs, and boost market recognition and sales.

Meat processing plants

Used for weight detection of pork, beef, mutton and other segmented meats, which can quickly screen out unqualified products, reduce waste and improve production efficiency.

Aquatic product processing plants

During the processing of fish, shrimp, shellfish and other products, conduct weight detection and sorting of products to ensure uniform product specifications, improve product quality and market competitiveness.

Fish and shrimp weight sorting equipment

The crayfish weight sorting machine is equipped with a high-precision weighing system that quickly detects individual weights and automatically sorts them into preset grades, significantly improving sorting efficiency and supporting standardized grading of crayfish and other aquatic products.

Recommended products

Boost Your Productivity with SameGram

Cooperation Cases

Fish Seafood Meat Industry Success Stories

Combination Weigher Optimizes Mixed Seafood Packs

“We produce assorted frozen seafood packs that include squid, shrimp, and mussels. With irregular sizes and moisture variations, manual weighing was too slow and inaccurate.

SameGram’s 12-head combination weigher intelligently pairs items to reach exact net weights. Overfill dropped by 60%, and our export compliance rate improved significantly in the first three months.”

Nguyen Hoang

Operations Manager at a Seafood Plant in Ho Chi Minh City, Vietnam

Inline Checkweigher Reduces Giveaway in Fresh Meat Trays

“Our fresh chicken tray line needed precise weight control to avoid excessive giveaway, especially for supermarket contracts. SameGram’s high-speed checkweigher gave us stable readings even with condensation on trays.

We now keep tray weight within ±1g, and our packaging cost per unit dropped by 8%. It’s become an essential tool for margin control.”

Anastasios Petrou

Quality Head at a Poultry Processor in Thessaloniki, Greece

Sorting System Elevates Grading Accuracy for Export Poultry

“We supply whole chickens and leg quarters to the Middle East and Japan. Our manual sorting system often misclassified sizes and damaged skin, leading to complaints.

After switching to SameGram’s 6-grade weight sorting machine, accuracy jumped to 99.2%, and skin damage rate fell sharply. We even passed a major buyer’s audit ahead of schedule.”

Fahad Al-Mutairi

Plant Director at a Meat Export Facility in Riyadh, Saudi Arabia

Free Sample Test

We offer free sample testing and demonstration setups customized to your product type and packaging format!

Why Partner with SameGram for Smart Manufacturing

From labor-intensive to data-driven

Real-time tracking of every gram

Seamless access to MES/ERP

Modular Scalable Remote Ready

Future Proof Architecture with Room to Grow

Remote Line Assessment and Custom Support

Get a Free Solution Plan

Contact our team of experts for:

- Free line evaluation

- Customized product testing

- Customized machine configuration

- Request a free consultation or Book a live demo

- ASK SameGram

- Mobile Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions