Top Features of Metal Detector Checkweigher Integrated Machines, Best Solution for Food Industry | Samegram

In the fast-paced world of food processing, pharmaceuticals, and manufacturing, ensuring product quality and safety is paramount. Metal detection checkweigher integrated machines combine the functionalities of an in-motion checkweigher—which verifies if product weights comply with design specifications and regulations—and a metal detector—which identifies unwanted metal contaminants that could violate safety standards. These systems streamline production lines by performing dual inspections in one compact unit, reducing space, costs, and errors. At Samegram, a leading provider of intelligent checkweighing and industrial weighing solutions with over 5,000 success stories, we specialize in high-precision systems like our SCM-4530L2 Dynamic Checkweigher with Metal Detector Combination System. This guide explores the top features of these integrated machines, drawing from industry-leading examples and our expertise to help you address real-world challenges such as compliance with HACCP, GMP, and FDA standards, minimizing recalls, and optimizing efficiency.

Why Integrated Metal Detection Checkweighers Matter

Standalone checkweighers and metal detectors are essential, but integrating them solves key pain points: fragmented inspections lead to higher costs, larger footprints, and potential transfer errors between systems. Integrated units ensure seamless operation, real-time data, and compliance. For instance, in food safety, undetected metal contaminants can cause recalls, while weight deviations result in overfill waste or underweight fines. Our Samegram systems, backed by our high-tech R&D team focused on precision algorithms and modular designs, deliver tailored dynamic weighing solutions for industries like food, pharmaceuticals, and cosmetics.

Based on insights from top manufacturers and our own innovations, here are the key features that make these systems indispensable. We've incorporated real parameters from Samegram's products to demonstrate practical value, ensuring you can evaluate how they resolve issues like inaccurate weights or hidden contaminants.

1. High-Precision Weighing Combination Machine for Accurate Compliance

A core feature is ultra-precise integrated checkweigher technology that verifies product weights against strict norms, preventing giveaway or shortages. This addresses user problems like regulatory non-compliance and material waste.

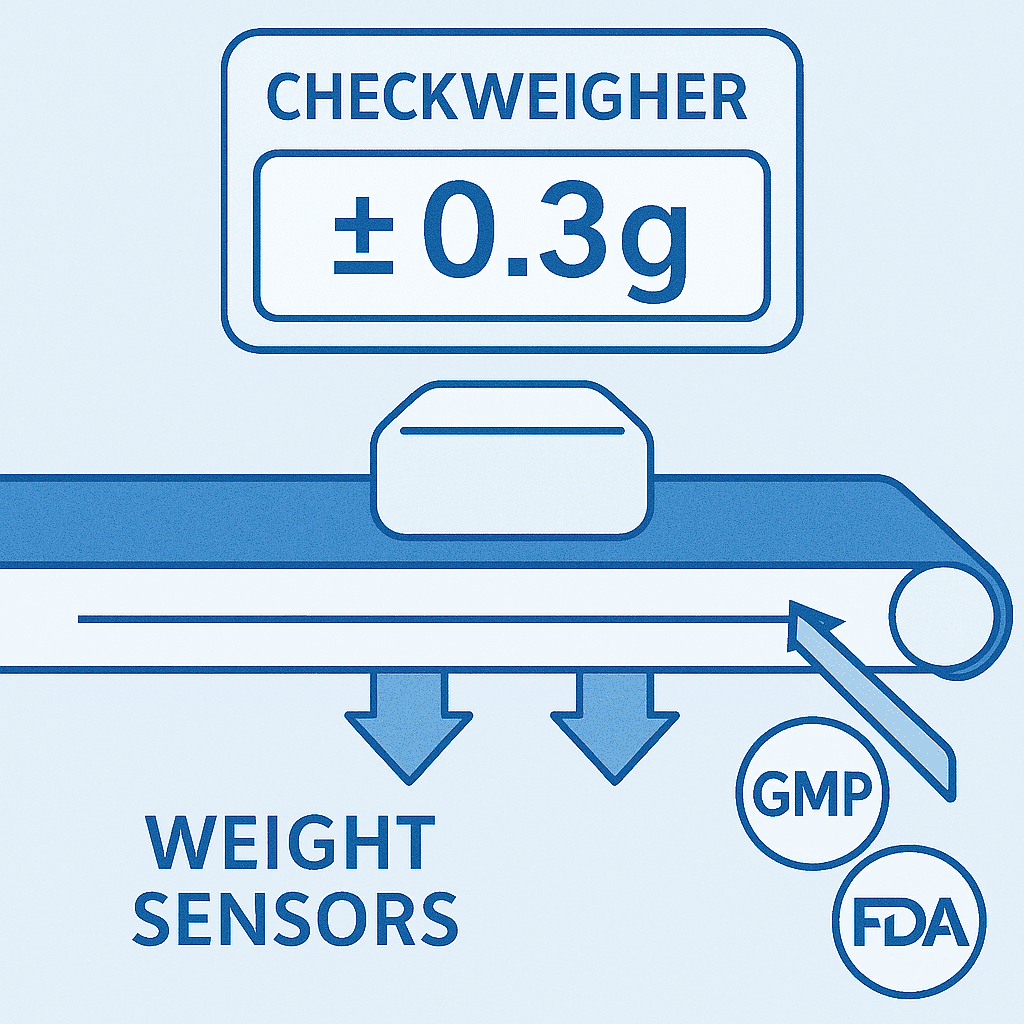

● Accuracy and Range: Systems offer weighing accuracy from ±0.02g to ±1g, with ranges up to 80kg. For example, Samegram's High Precision and Ultra Fast Checkweigher achieves ±0.3-1g accuracy for 1-2000g products, using digital weighing sensors for real-time detection.

● Speed: Handles up to 300 pieces per minute, minimizing bottlenecks in high-volume lines.

● Samegram Advantage: Our inline solution, SCM-4530L2 model features a 0.1g display division and adjustable belt speeds of 5-28m/min, ensuring compliance in pharmaceuticals where exact dosages are critical. This reduces labor costs by up to 40%, as seen in our Belarus food processing case study.

2. Sensitive Metal Detector & Checkweigher Combo for Contaminant-Free Products

Integrated metal detectors use electromagnetic induction to spot ferrous, non-ferrous, and stainless steel contaminants, solving safety issues in food and pharma where metals from machinery can contaminate products.

● Detection Sensitivity: Capable of detecting metals as small as 0.6mm (ferrous) to 2.0mm (stainless steel), with multi-frequency scanning for complex products.

● Product Effect Compensation: Advanced algorithms ignore product signals (e.g., moisture in food) for reliable detection without false alarms.

● Samegram Advantage: The SCM-4530L2 offers sensitivity of 0.6-1.2mm for ferrous metals and supports hygienic designs for easy cleaning, ideal for potato chips or canned pharmaceuticals where contaminants could lead to recalls. Our systems integrate seamlessly, reducing false rejects and ensuring traceability.

3. Compact and Hygienic Design for Efficient Production Lines

Space-saving combination machine is a game-changer for factories with limited room, combining functions into one unit to cut footprint by up to 50%.

● Footprint and Materials: Stainless steel (304 grade) construction with IP65/IP69 ratings for washdown environments, meeting GMP/ISO standards.

● Ease of Cleaning: Modular, no-dead-end designs prevent bacterial buildup, crucial for food safety.

● Samegram Advantage: Our models feature fully enclosed, flushable structures and anti-oxidation materials, supporting high-hygiene needs in agriculture and cosmetics. This design facilitates quick maintenance, reducing downtime in busy lines.

4. Independent Rejection Systems to Minimize Waste

Automated rejection separates metal contaminants from weight issues, addressing over-rejection problems that waste good products.

● Mechanisms: Push rod, air-blast, or sliding types, with dual bins for sorted rejects.

● Efficiency: Reduces false positives, saving up to 50% on waste as in dairy applications.

● Samegram Advantage: SCM-4530L2 includes optional push rod or sliding rejection, with independent modes for precise sorting in sanitary pads or snack production. This ensures root-cause analysis and compliance.

5. User-Friendly Interface and Data Tracking Integration

Intuitive controls and connectivity solve operational challenges like training time and data silos.

● Touchscreen HMI: Single interface for both functions, with multilingual support and real-time stats.

● Data Features: USB/Ethernet export, MES/ERP integration for traceability and OEE monitoring.

● Samegram Advantage: Our systems store up to 100 formulas and offer remote diagnostics, backed by lifetime maintenance and a 12-month warranty. This empowers users to track production and comply with audits effortlessly.

6. Versatile Easy Maintenance Applications Across Industries

These combination machines adapt to diverse needs, from food to pharma, ensuring broad problem-solving.

● Food Industry: Detects metals in snacks and verifies weights to meet retail specs.

● Pharmaceuticals: Ensures contaminant-free tablets with precise dosing.

● Samegram Advantage: Proven in over 5,000 cases, our SCM-4530L2 excels in potato chips (weight tolerance) and canned meds (metal screening), reducing recalls and boosting efficiency.

Benefits: Solving Real User Problems

● Food Safety Compliance: Prevents recalls by detecting contaminants and ensuring weights meet norms, aligning with HACCP and BRC.

● Cost Savings: Reduces space, labor, and waste—our systems cut labor by 40% in case studies.

● Efficiency Gains: High speeds (up to 300 ppm) and minimal downtime via easy maintenance.

● Sustainability: Lowers energy use and material waste, supporting eco-friendly manufacturing.

SCM-4530L2 is a dynamic weighing checkweigher metal detector combination system, ideal for food processing and pharmaceutical applications on compact lines.

Categories Checkweigher Combination System

Brand: SameGram

Model: SCM-4530L2

Weighting range: 1-2000g

Belt speed: 5-28m/min

Weighting accuracy: ±0.3-1g

Size of golden inspection: H 120mm*W 300mm

Size of weighing section: L≤200mm; W≤120mm;H≤100mm

Size of inspection section: L 450mm*W 230mm

Sensitivity of metal detection empty machine: Fe:0.6-1.2mm, Not Fe:0.8-1.5mm, Sus: 1.2-2.0mm

Rejection mode: Push rod type, sliding type are optional

Why Choose Samegram for Your Inline Checkweigher and Metal Detector Needs

As a high-tech enterprise with a focus on innovation, Samegram has built trust through customized, modular solutions for smart factories. Our R&D-driven approach ensures systems like the SCM-4530L2 deliver unmatched precision and reliability. With free sample testing, on-site demos, and global support, we're committed to your success. Visit our homepage or learn more about our company to see how we've helped industries worldwide.

Ready to Enhance Your Production Line?

Contact Samegram today for a free consultation or demo of our integrated systems. Ensure your products are safe, compliant, and efficient—reach out via our contact page.