Metal Detection in the Food Industry: Ensuring Safety and Compliance

In today's food industry, ensuring product safety and quality is non-negotiable. A critical component of this process is metal detection, which safeguards food products by identifying and removing metal contaminants during production. Whether it's a tiny fragment from machinery or a shard from raw material processing, a metal detector in food processing industries is essential for protecting consumers, maintaining compliance, and preserving brand integrity. At SameGram, we provide advanced industrial metal detector solutions designed to meet the rigorous demands of food manufacturers, ensuring your products are safe and compliant with global standards.

Why Metal Detection is Crucial in the Food Industry

Metal contamination poses a significant threat in food production. Contaminants like ferrous (iron), non-ferrous (aluminum, copper), and stainless steel can enter products at various stages—harvesting, processing, or packaging. Without effective detection, these contaminants can lead to:

● Health Risks: Metal fragments can cause choking, dental damage, or internal injuries to consumers.

● Recalls and Fines: Contaminated products trigger expensive recalls and regulatory penalties, damaging profitability.

● Reputation Loss: A single incident can erode consumer trust and harm your brand’s standing.

A metal detector acts as a frontline defense, ensuring that contaminants are identified and removed before products leave the factory. Benefits include:

● Enhanced food safety and consumer protection.

● Compliance with standards like HACCP, ISO, BRCGS, and FDA.

● Reduced risk of costly recalls and legal issues.

At SameGram, our food industry metal detectors deliver unmatched sensitivity and reliability, helping food manufacturers worldwide maintain the highest safety standards.

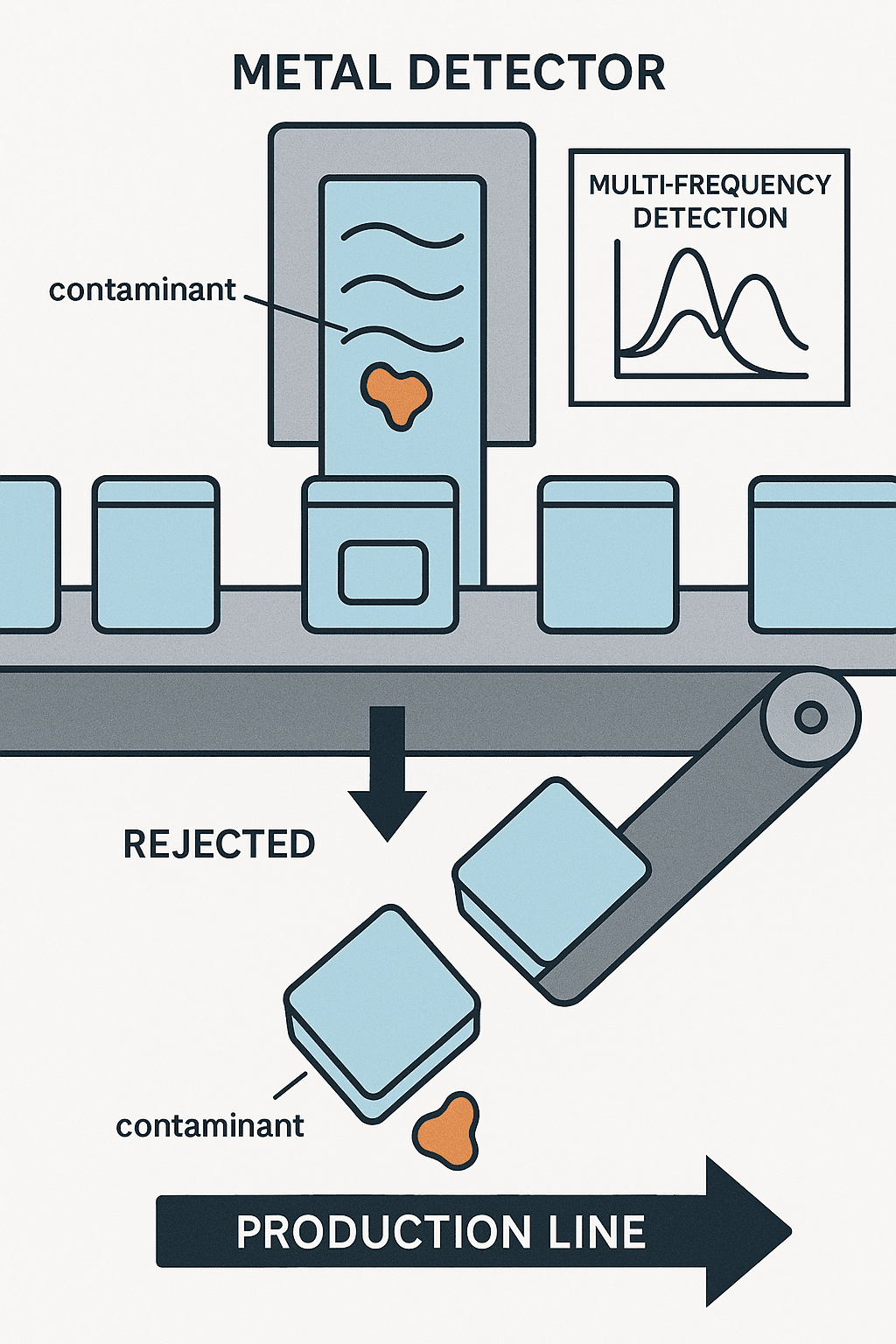

Understanding how a food industry metal detector functions can help you choose the right solution for your production line. Here’s the basic process:

● Electromagnetic Field Generation: The detector creates a magnetic field as products pass through, typically on a conveyor or in free-fall systems.

● Detection of Disruptions: Metal contaminants disrupt the field, triggering an alert.

● Automatic Rejection: Contaminated products are diverted from the line using pneumatic rejectors or other mechanisms.

SameGram’s food industry metal detectors use advanced multi-frequency signal processing to detect all metal types—ferrous, non-ferrous, and stainless steel—even in challenging conditions like foil packaging or wet environments.

The DD-500 Series is an advanced conveyor belt metal detector using smart touch-screen control. Ideal for food production and other

Categories Metal Detector

Brand: SamaGarm

Model: DD-500 series

The maximum conveyable weight: 0-200KG

The conveying speed: 25m/m fixed speed or customized speed adjustment

Power supply: AC220V±10% 50-60Hz, customizable voltage

Advanced Metal Detection Technology by SameGram

SameGram leverages cutting-edge technology to provide superior metal detector solutions for the food industry. Our systems feature:

● Multi-Frequency Detection: Enhances sensitivity across all metal types, reducing false rejects.

● Foil-Compatible Design: Detects contaminants in aluminum-foil-sealed products, overcoming a common limitation of traditional detectors.

● Moisture-Proof and Auto-Calibrating: Ensures consistent performance in humid or wet conditions without manual adjustments.

● Touchscreen Interface: Simplifies operation, setup, and product learning for your team.

These innovations make SameGram metal detectors ideal for diverse applications, including baked goods, dairy, meats, and bulk powders.

Learn More About SameGram's Industrial Food Metal Detector Solutions

At SameGram, we offer a range of industrial metal detector systems tailored to food production needs:

● Advanced Conveyor Belt Metal Detector DD-720 Series: Perfect for packaged goods, with sensitivity down to Fe 0.5mm and SUS 0.7mm.

● End-of-Line Conveyor Metal Detector for Food Safety DD-360 Series: High-speed detection for food-grade conveyor industrial metal detector systems.

● High Precision Conveyor Metal Detector DD-390 Series: Customizable with dual-frequency technology for maximum accuracy.

● Free Fall Metal Detectors: Ideal for bulk powders and granules, ensuring contaminants are caught before packaging.

● Combination Systems: Integrate metal detection with checkweighers for comprehensive food safety quality control in a single unit.

Our modular designs allow seamless integration into your existing production lines, with scalability for future upgrades.

Ensuring Compliance with Industry Standards

Compliance with food safety regulations is a top priority. SameGram's metal detectors help you meet:

● HACCP and ISO: Prevent metal contamination at Critical Control Points (CCPs).

● BRCGS and SQF: Regular calibration and validation ensure adherence to these global standards.

● FDA and USDA: Meet U.S. export requirements with certified performance.

We provide:

● Installation and Commissioning: Expert setup for optimal performance.

● Calibration Services: Certified checks to maintain accuracy and compliance.

● Documentation: Detailed records for audits and regulatory reviews.

Success Stories of Industrial Metal Detector Machine: SameGram in Action

Our metal detectors have transformed quality control for food manufacturers globally. For example:

● East China Bakery: A leading baked goods processor struggled with false alarms due to foil packaging. After installing SameGram’s DD-720 with dual-frequency technology, they reduced false rejects by 85%, achieved 99.8% detection accuracy, and boosted output by 18%, meeting HACCP and ISO22000 for exports.

This demonstrates how SameGram’s solutions solve real-world problems, enhancing safety and efficiency.

Why Choose SameGram for Your Metal Detector Needs?

When selecting a metal detector, SameGram offers distinct advantages:

● Precision: Detects contaminants as small as 0.5mm with high accuracy.

● Customization: Tailored to your product type, packaging, and line speed.

● Reliability: IP65-rated for harsh environments, with minimal maintenance.

● Support: From installation to ongoing technical assistance, our team ensures your success.

With over a decade of expertise, SameGram is a trusted partner in food safety and industrial automation.

Practical Tips for Metal Detection in Food Production

To get the most from your metal detector, follow these actionable steps:

● Match the Detector to Your Product: Use conveyor systems for packaged goods and free-fall detectors for bulk items.

● Calibrate Regularly: Test with certified standards (e.g., ferrous, non-ferrous, stainless steel test pieces) to ensure accuracy.

● Train Your Team: Educate staff on operation, troubleshooting, and maintenance.

● Monitor Performance: Use data from the detector to identify contamination trends and improve processes.

Need help choosing? Contact SameGram for a free consultation.

Related Hot-sale Metal Detector

HC-700 gravity fall metal separator offer precise,hygienic and sealed metal removal for food and pharma use.

DD-220 is a food conveyor metal detector designed for aluminum foil packaging,with high sensitivity and easy integration.

DD-360 Series is a food-grade metal detector conveyor system. Ideal for food industry and food production lines.

Customizable metal detector for conveyor belt with dual frequency, high sensitivity, and strong anti-interference.

DD-500 Series is an advanced conveyor belt metal detector using smart touch-screen control. Ideal for food production and other