Industrial Metal Detectors: Complete Selection & Best Practices Guide

In today's fast-paced manufacturing world, ensuring product safety is more critical than ever. Metal detectors play a vital role in industries like food processing, pharmaceuticals, and packaging, where even tiny metal contaminants can lead to costly recalls, health risks, or regulatory violations. These devices help identify ferrous, non-ferrous, and stainless steel impurities inside products, safeguarding both consumers and businesses. As a leading provider of industrial automation solutions, SameGram has been at the forefront of this technology for over 20 years, delivering high-precision metal detection systems to more than 5,000 clients across 60 countries. In this guide, we'll explore best practices for implementing metal detection, backed by real-world examples, and highlight how our innovative solutions can elevate your production line.

Understanding Metal Detection Principles

At its core, a metal detector uses electromagnetic fields to spot unwanted metal particles. Typically, it features a transmitter coil that creates a magnetic field, illuminating any metal as it passes through. Receiver coils then pick up disturbances caused by the metal's conductive or magnetic properties, triggering an alert or rejection. This balanced coil system works well for most products, detecting everything from iron fragments to stainless steel shards.

For products in foil packaging, a specialized magnetic field approach magnetizes ferrous metals, generating a detectable current. Factors like product moisture, salt content, or packaging can influence performance—wet or conductive items might create a "product effect" that mimics metal signals, so systems must compensate for this to avoid false alarms.

SameGram's metal detectors, such as our DD-360 End of Line Conveyor Metal Detector, incorporate advanced multi-frequency signal processing to handle these challenges. With sensitivity levels detecting ferrous metals as small as 0.6mm and stainless steel up to 1.2mm, they ensure reliable operation even in demanding environments. Our IP65-rated designs resist water and dust, making them ideal for high-humidity settings like dairy or meat processing.

Best Practices for Selecting and Integrating Metal Detectors

Choosing the right metal detector starts with assessing your production needs. Consider the types of contaminants you're targeting, product characteristics, and line speed. Smaller apertures generally offer better sensitivity, as detection is strongest at the center. For high-throughput lines, opt for systems that integrate seamlessly with conveyors or pipelines.

Placement and Installation

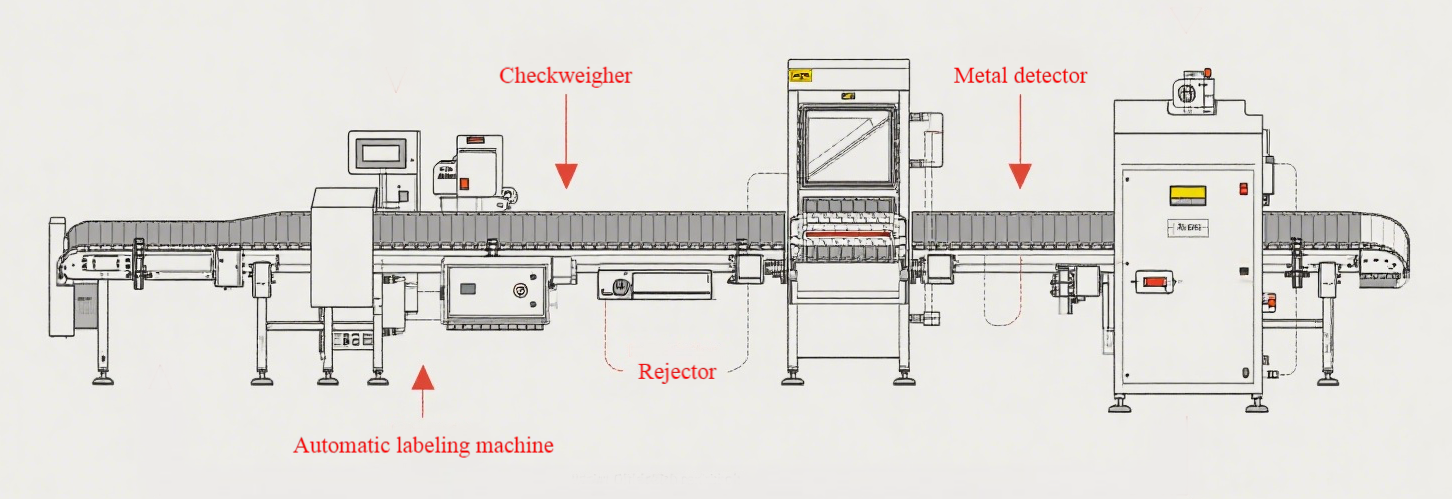

Position your detector at critical control points, ideally after packaging to catch contaminants from upstream processes. Early placement can prevent damage to machinery, while end-of-line checks ensure final product integrity. In a HACCP plan, identify hotspots like raw material intake or mixing stages.

For smooth integration, ensure adequate space for rejection mechanisms—such as push rods or air blasts—to remove faulty items without halting production. SameGram's conveyor systems, like the High Precision Conveyor Metal Detector DD-390 Series, feature modular designs that bolt onto existing lines, with adjustable speeds up to 25m/min. Our experts provide on-site installation and commissioning, minimizing downtime.

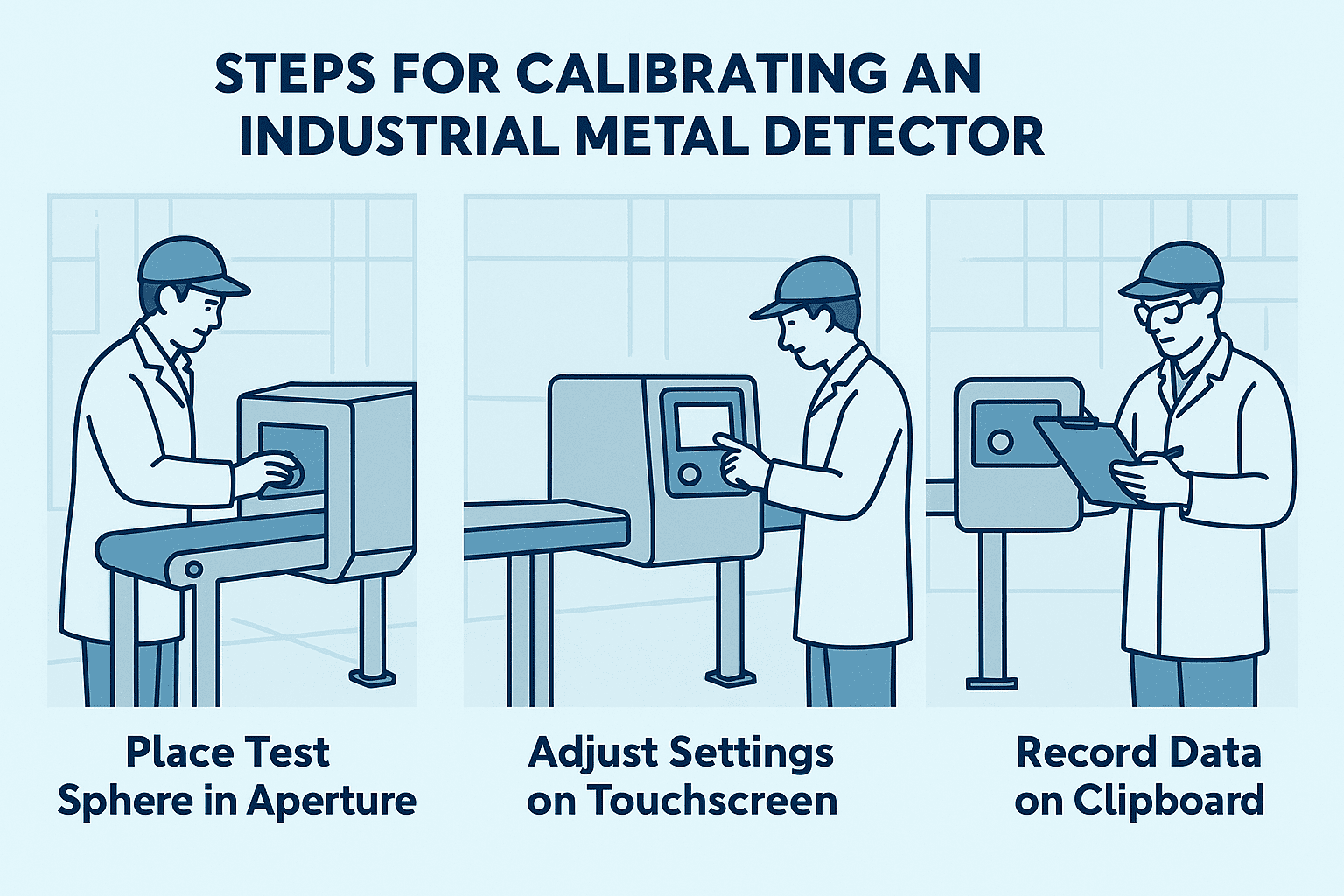

Calibration and Sensitivity Optimization

Calibration is key to balancing sensitivity and efficiency. Test with sample contaminants (ferrous and non-ferrous spheres) to fine-tune settings for each product run. Adjust for environmental factors like temperature or electromagnetic interference, which can cause instability.

Limit access to controls with passwords or user-level permissions to prevent unauthorized tweaks. SameGram systems, including our SCM-4530L2 combination unit, auto-adjust frequencies based on product properties, reducing false rejects. With accuracy like ±0.3g for weighing and Fe detection down to 0.6mm, they handle weights from 1-2000g, perfect for varied items like snacks or pharmaceuticals.

Maintenance and Testing Protocols

Regular maintenance keeps detectors running smoothly. Clean components daily, especially in wet environments, and schedule preventive checks for coils and sensors. Use environmental simulations to test under real conditions.

Testing should occur at shift starts, product changes, and hourly intervals. Pass test packs through the system twice—once at the leading edge, once at the trailing—to verify rejection. If a test fails, isolate affected batches and re-screen them.

At SameGram, we emphasize rigorous quality control in our 4000-square-meter factory, with processes like IQC, PQC, and FQC ensuring every unit meets CE and ISO9001 standards. Our lifetime technical support includes remote diagnostics and training, helping you maintain peak performance.

Real-World Examples of Metal Detection in Action

Let's look at how these practices translate to success on the ground.

In a busy snack food plant, frequent false alarms from salty products were causing unnecessary downtime. By implementing a multi-frequency detector with product effect compensation, the team reduced rejects by 40%. The system detected a 1mm stainless steel fragment from a worn sieve, preventing a potential recall. Drawing from our experience, SameGram customized a similar setup for a client in the food sector, integrating it with their checkweigher for dual checks, boosting throughput while maintaining compliance.

Another example comes from pharmaceutical packaging, where hygiene is paramount. A line handling tablets faced issues with metal from upstream machinery. Installing a free-fall detector early in the process caught contaminants before they reached final packing. With stainless steel construction and GMP-compliant materials, the setup ensured sterile operations. One of our pharmaceutical partners reported zero contamination incidents after adopting SameGram's Advanced Conveyor Belt Metal Detector DD-720, which features high sensitivity (Fe 0.5mm) and easy cleaning, aligning with FDA guidelines.

In logistics for cosmetics, a combined system tackled both weight and metal checks. Overweight jars with hidden metal shards were flagged and rejected independently, improving accuracy. SameGram's SCM-4530L2 Checkweigher with Metal Detector Combination System, with its touchscreen interface and MES/ERP integration, allowed real-time tracking, cutting waste by 25% for a major client.

These cases underscore the value of tailored solutions. With over 5,000 installations worldwide, SameGram has helped industries avoid recalls and enhance efficiency, proving our systems' reliability in diverse scenarios.

Why Choose SameGram for Your Metal Detection Needs

As a high-tech enterprise specializing in automation, SameGram stands out with our in-house R&D and manufacturing. Our metal detectors aren't just tools—they're comprehensive solutions built for precision and durability. From the End of Line Conveyor Metal Detector DD-360 (sensitivity: Fe ≥0.6mm) to the Aluminum Foil Pack Metal Detector DD-220, we cover all bases.

Our combination systems, such as the SCM-4530L2 Metal Detector Combination System, merge metal detection with checkweighing in a compact footprint, using electromagnetic induction and digital sensors for spot-on results. Features like USB data export, 100 recipe storage, and stainless steel builds make them user-friendly and compliant.

We offer free sample testing, 12-month warranties, and global support, ensuring you get the right fit. Whether you're upgrading an existing line or starting fresh, our customizable options promote intelligent, sustainable operations.

Conclusion

Implementing effective metal detection isn't just about compliance—it's about building trust and efficiency in your operations. By following these best practices, from strategic placement to rigorous testing, you can minimize risks and maximize output. At SameGram, we're committed to advancing industrial weighing and detection with innovative, reliable systems. Contact us today for a consultation and see how our expertise can transform your production line.

Related Hot-Sale Metal Detectors

DD-720 is a belt conveyor metal detector with unmatched sensitivity, ideal for food and pharma.

DD-500 Series is an advanced conveyor belt metal detector using smart touch-screen control. Ideal for food production and other

Customizable metal detector for conveyor belt with dual frequency, high sensitivity, and strong anti-interference.

HC-700 gravity fall metal separator offer precise,hygienic and sealed metal removal for food and pharma use.

DD-220 is a food conveyor metal detector designed for aluminum foil packaging,with high sensitivity and easy integration.