How Conveyor Metal Detector Systems Boost Manufacturing Efficiency

In today's fast-paced manufacturing world, ensuring product quality while keeping production lines running smoothly is a top priority. Conveyor metal detector systems play a crucial role in this by detecting unwanted metal contaminants that could disrupt operations or compromise safety. As a leading provider of intelligent weighing and inspection solutions, SameGram has been at the forefront of developing these systems for over 20 years. Our metal detectors, designed for industries like food, pharmaceuticals, and cosmetics, help manufacturers avoid costly downtime and maintain high standards. In this article, we'll explore how these systems boost efficiency, drawing from real-world applications and insights from our extensive experience serving more than 5,000 clients across 60 countries.

Understanding Conveyor Metal Detector Systems

Conveyor metal detector systems are specialized tools that integrate seamlessly into production lines to scan products for metal impurities. These impurities might come from raw materials, machinery wear, or even accidental inclusions during handling. Unlike manual inspections, which are time-consuming and prone to human error, these automated systems use electromagnetic fields to identify ferrous, non-ferrous, and stainless steel contaminants with remarkable precision.

At SameGram, our conveyor metal detectors, such as those in the End of Line Conveyor Metal Detector DD-360 and High Precision Conveyor Metal Detector DD-390 series, are built with advanced multi-frequency technology. This allows them to adapt to different product properties, reducing false alarms and ensuring reliable detection. For instance, the End of Line Conveyor Metal Detector DD-360 offers sensitivity levels as fine as Fe ≥0.6mm, Non-Fe ≥0.8mm, and SUS ≥1.2mm, making it ideal for high-speed lines where accuracy can't be sacrificed. These systems are customizable, with detection channels ranging from 80–1000mm in width and 300–1200mm in height, fitting various product sizes without slowing down the process.

The core principle involves generating an electromagnetic field around the conveyor belt. As products pass through, any metal disrupts this field, triggering an alert. Rejection mechanisms—like push rods or air blasts—then remove the contaminated item automatically. This not only prevents defects from reaching the end of the line but also protects downstream equipment from damage, which is a common cause of unexpected shutdowns.

Key Ways These Systems Enhance Manufacturing Efficiency

Manufacturers often face challenges like production bottlenecks, waste from contaminated batches, and regulatory compliance issues. Conveyor metal detector systems address these head-on by streamlining operations and minimizing risks. Let's break down the main benefits.

Reducing Downtime and Maintenance Costs

One of the biggest efficiency killers in manufacturing is unplanned downtime. Metal contaminants can jam machinery, leading to hours or even days of lost production. By detecting and ejecting these issues early, conveyor systems keep lines moving. For example, in food processing, where raw ingredients might carry metal fragments from harvesting equipment, early detection prevents entire batches from being scrapped.

SameGram's systems excel here with their robust design and IP65 protection rating, which guards against dust and water—common in washdown environments. Our Digital Conveyor Metal Detector DD-500 Series, capable of handling up to 200KG loads at 25m/min, includes smart touchscreen controls for quick adjustments, meaning operators can resolve minor issues without halting the line. In our experience, clients have reported up to 20% reductions in maintenance time after integrating these detectors, as they catch problems before they escalate.

Practical tip: Position the detector midway through the line, after initial processing but before packaging. This allows for targeted inspections without disrupting the flow. If you're dealing with variable speeds, opt for models with adjustable frequency to match your throughput.

Improving Product Quality and Reducing Waste

Efficiency isn't just about speed—it's about producing more usable output. Metal detectors ensure that only contaminant-free products proceed, cutting down on rework and waste. In pharmaceuticals, where even tiny metal particles could violate safety regs, this is critical. The systems' high sensitivity helps meet standards like HACCP and ISO22000, avoiding recalls that could cost millions.

Take our SCM-4530L2 Checkweigher with Metal Detector Combination System, which merges metal detection with checkweighing. It handles weights from 1-2000g with ±0.3-1g accuracy and detects metals as small as Fe 0.6-1.2mm. By combining functions in one unit, it saves space and reduces handling steps, boosting throughput by up to 28m/min. Users in the snack food sector have used this to sort potato chips efficiently, rejecting only the faulty ones and keeping waste under 1%.

To solve real problems: If your line handles foil-packaged goods, our DD-220 Aluminum Foil Pack Metal Detector specializes in aluminum foil detection, ensuring no false positives from packaging. This maintains efficiency in high-volume runs, where manual checks would be impractical.

Enhancing Compliance and Brand Protection

Regulatory compliance is non-negotiable, especially in food and pharma. Metal detectors provide documented proof of quality control through data logging and USB exports. SameGram's systems integrate with MES/ERP platforms for real-time tracking, making audits straightforward.

Beyond compliance, these systems protect your brand. A single contaminated product reaching consumers can damage reputation overnight. By preventing this, you build trust and open doors to new markets. Our global clients, from logistics to cosmetics, appreciate how our detectors support sustainable practices by reducing waste and energy use through precise, modular designs.

Boosting Overall Throughput

Integrated systems like ours allow for faster line speeds without sacrificing safety. The High Precision Conveyor Metal Detector DD-390, with dual-frequency tech, operates at 1–1000m/min, adapting to peak demands. This scalability means you can ramp up production during busy seasons without adding extra equipment.

A common issue we help solve: Electromagnetic interference from nearby machines. Our detectors use algorithms to filter this out, ensuring stable performance. For bulk materials, our free-fall variants complement conveyor setups, creating a comprehensive detection network.

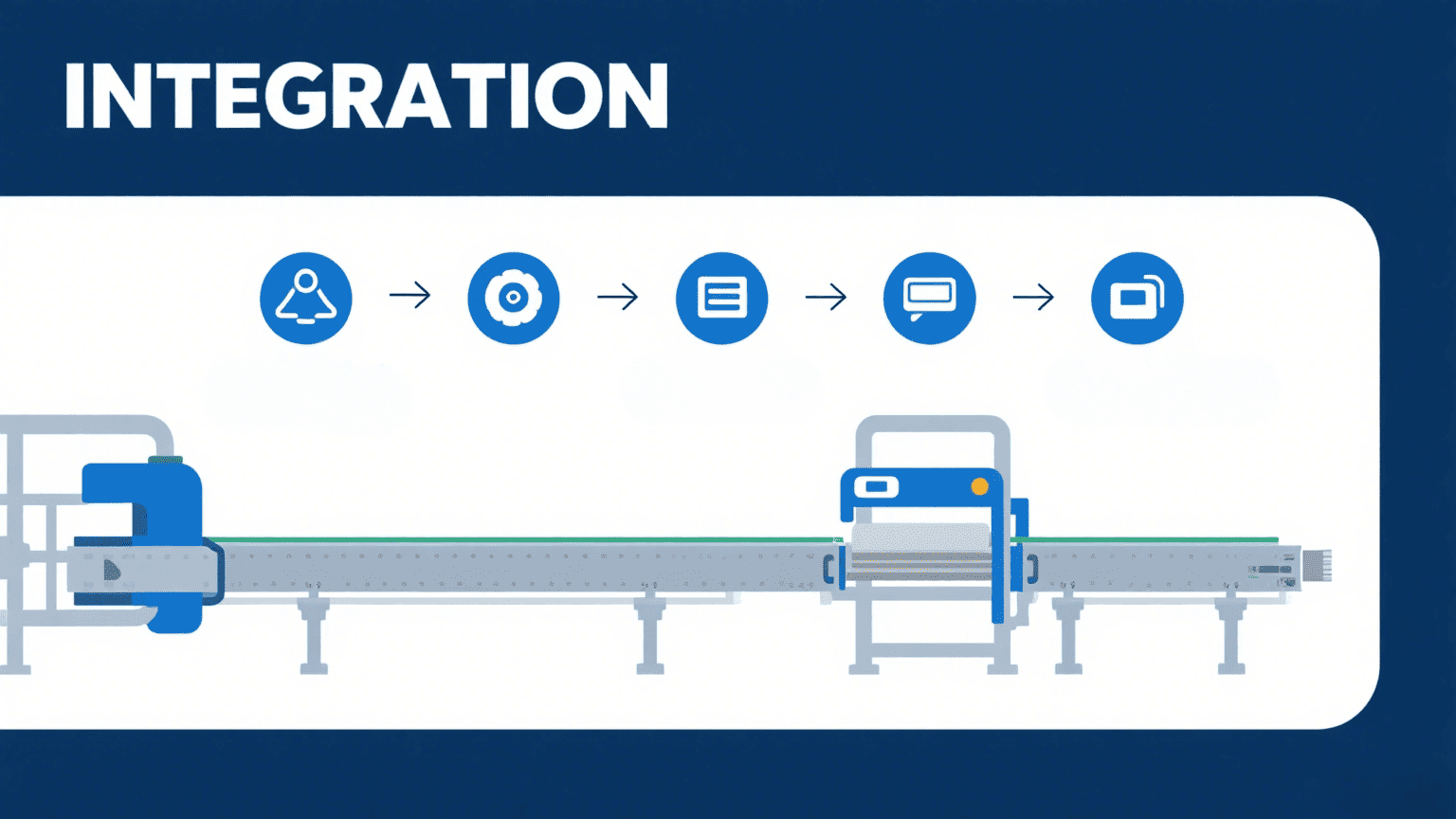

Integrating Conveyor Metal Detectors into Your Production Line

Integration doesn't have to be complicated. Start by assessing your line's layout—consider product type, speed, and space. SameGram offers modular options that fit existing conveyors, with widths and heights tailored to your needs.

Our factory in China, spanning over 4,000 m², uses bending machine and laser cutting for precise builds. With daily production of over 200 parts and stock for quick delivery, we ensure minimal disruption during installation. We provide on-site demonstrations, free sample testing, and 12-month warranties, plus lifetime support.

For a smooth rollout:

1. Map contaminant risks in your process.

2. Choose sensitivity based on product (e.g., higher for dense items).

3. Train staff via our intuitive interfaces—no experts needed.

4. Monitor data to fine-tune over time.

Clients integrating our SCM-4530L2 Checkweigher with Metal Detector Combination System have seen 15-20% efficiency gains, thanks to its compact footprint (450mm x 230mm inspection area) and independent rejects for weight and metal issues.

Why Choose SameGram for Your Metal Detection Needs

As a high-tech enterprise focused on automation, SameGram stands out with our commitment to innovation and quality. Our in-house manufacturing adheres to CE, ISO9001, and GMP standards, using FDA-compliant materials. We've delivered over 5,000 units worldwide, customizing solutions for tight spaces or high-compliance needs.

Our metal detectors aren't just tools—they're partners in efficiency. With features like auto-learning for products and remote diagnostics, we help you stay ahead. Whether it's the DD-720 Advanced Conveyor Belt Metal Detector for small channels or full combo systems, we draw from 20 years of R&D to deliver reliability.

Conclusion: Elevate Your Manufacturing with Proven Solutions

Conveyor metal detector systems are essential for modern manufacturing, turning potential pitfalls into opportunities for growth. By reducing downtime, waste, and risks, they directly improve efficiency and profitability. At SameGram, we're dedicated to providing these solutions with unmatched support.

Ready to optimize your line? Contact us today for a free consultation or sample test. Visit our website at samegram.com to explore more.

Hot-Sale Metal Detector

DD-720 is a belt conveyor metal detector with unmatched sensitivity, ideal for food and pharma.

DD-500 Series is an advanced conveyor belt metal detector using smart touch-screen control. Ideal for food production and other

HC-700 gravity fall metal separator offer precise,hygienic and sealed metal removal for food and pharma use.

DD-360 Series is a food-grade metal detector conveyor system. Ideal for food industry and food production lines.

SCM-4530L2 is a checkweigher metal detector combination system ,ideal for food processing and pharmaceutical on compact lines.