Consumer Electronics and Toy Industry

The consumer electronics industry encompasses a wide range of smart devices, including smartphones, tablets, smart home devices, wearables, and automotive electronics. The toy industry, on the other hand, includes diverse products such as building sets, educational toys, remote-controlled toys, and plush toys, characterized by varied and complex structures.

This industry demands exceptionally high standards for product quality and assembly integrity. During packing, packaging, and shipping, the absence of a single screw, battery, or small accessory can lead to returns, complaints, or even damage to brand reputation.

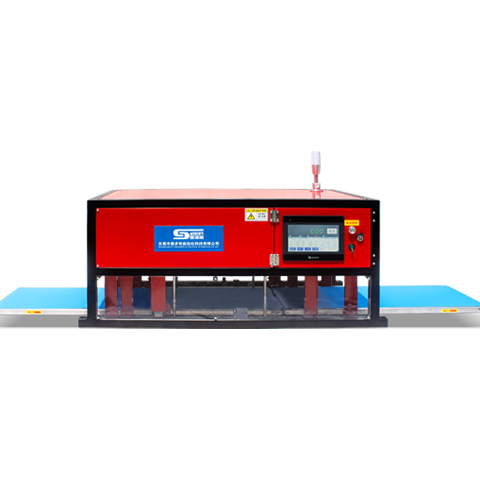

SameGram’s dynamic checkweighers and weight sorting machines play a critical role in this process. By precisely detecting product weight, they automatically identify missing or incorrectly assembled components and remove defective items in real-time, effectively ensuring shipment quality and production efficiency.

difficulty

Industry Challenges

Risk of Missing Parts in Packaging

The variety and intricacy of electronic components and toy parts often lead to missing or omitted items during packing, resulting in customer returns and increased rework rates.

Weight Discrepancies

Inconsistencies between the actual product weight and the standard weight after packaging can lead to quality issues or incorrect shipments, impacting customer trust and after-sales costs.

Fast Production Line Pace

The rapid pace of consumer electronics and toy production lines demands high-speed, highly stable inspection equipment to keep up, otherwise production bottlenecks occur.

Electrostatic Interference

Electronic components and plastic toys are prone to static electricity, which can cause significant drift and poor repeatability in weighing results, affecting checkweighing accuracy.

Lack of Data Traceability

Scattered data across the production process hinders linkage, making it difficult to quickly identify the cause of quality issues. Establishing a comprehensive data traceability system enables rapid retrieval of product information from raw materials to final shipment, facilitating quick identification of quality issues and continuous improvement.

Application Scenarios

Automated weighing and price labeling system for pre-packaged boxed electronic products

High-precision online checkweighing system for block-assembled toys

Automated checkweigher for smart home appliance packaging lines

Dynamic checkweigher configurable with automatic cartoning machines

End-of-line defect rejection system for missing or incomplete components in electronic product packaging

Recommended products

Boost Your Productivity with SameGram

Cooperation Cases

Trusted by Industry Leaders

Consumer Electronics & Toy Manufacturer

Application: High-speed precision weighing and quality check before packaging

“SameGram's advanced checkweigher has completely transformed our packaging line. It detects underweight or overweight items before they reach the box sealer — crucial for maintaining brand consistency and preventing customer complaints. With its real-time alerts and data logging, we’ve significantly reduced return rates and boosted customer satisfaction.”

Key Benefits

• Real-time weight verification improves final product quality

• Fast, non-stop operation — maintains 120 ppm speed

• Reduces product returns due to weight deviations by over 80%

• Seamless integration with our ERP system for data traceability

Building Blocks Toy Factory

Application: High-accuracy weight inspection for multi-piece toy sets

“Each toy set we produce contains dozens of tiny pieces. SameGram’s precision checkweigher ensures no part is missing during assembly or packaging. It’s fast, accurate, and easy to adjust for different SKUs — essential for our high-volume operations.”

Key Benefits

• Detects underweight kits caused by missing components

• Adapts quickly to different toy set formats

• Prevents customer dissatisfaction and refund requests

• Streamlines QA with intuitive touchscreen controls

Smart Home Appliance Assembly Line

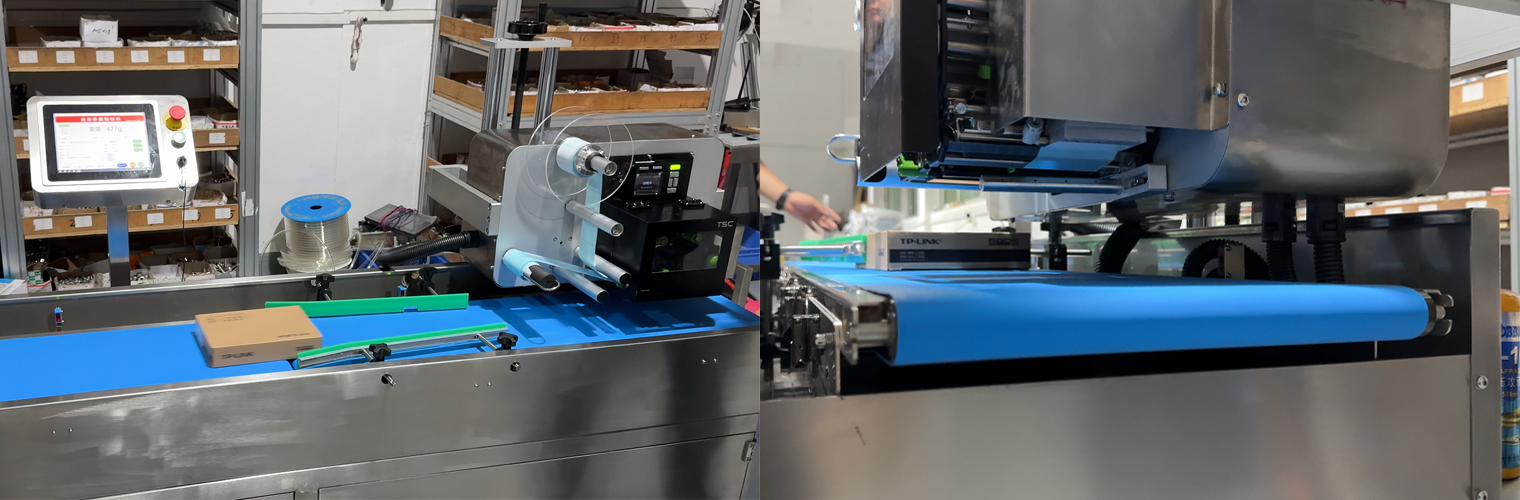

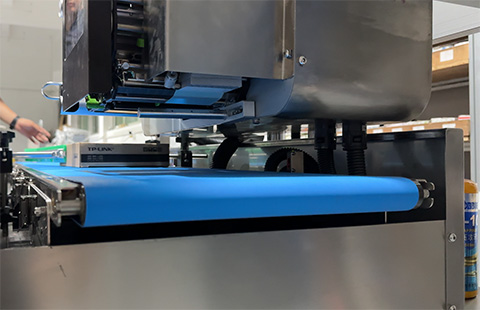

Application: End-of-line automatic checkweighing and label printing integration

“With SameGram’s dynamic checkweigher integrated into our smart appliance packaging line, we’ve achieved full automation from final inspection to labeling. The system immediately flags missing components or weight deviations, ensuring every boxed unit meets quality standards before shipping.”

Key Benefits

• Inline automatic weighing + barcode/price labeling

• Guarantees no missing screws, manuals, or accessories

• Boosts end-of-line QA efficiency by 60%

• Reduces customer complaints and logistics returns

Free Sample Test

We offer free sample testing and demonstration setups customized to your product type and packaging format!

Why Partner with SameGram for Smart Manufacturing Solutions?

From labor-intensive to data-driven

Real-time tracking of every gram

Seamless access to MES/ERP

Modular Scalable Remote Ready

Future Proof Architecture with Room to Grow

Remote Line Assessment and Custom Support

Get a Free Solution Plan

Contact our team of experts for:

- Free line evaluation

- Customized product testing

- Customized machine configuration

- Request a free consultation or Book a live demo

- ASK SameGram

- Contact SameGram

- Metal Detector Checkweigher Selection Table

- Checkweigher Selection Registration Form

- Labeling technical parameters

- Tel

- Tel

- Tel

- Tel

- Tel

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions