Intelligent X-ray Inspection System Solutions from Source to Shelf

The "Time Bomb" in Your Final Product: A tiny shard of metal or glass, hidden within perfect packaging, is all it takes to detonate a crisis of brand trust. Are you losing sleep over that one-in-a-million chance?

The "Snowball Effect" of Raw Material Contamination: A single stone mixed in with your bulk ingredients gets processed, contaminating the entire batch and causing your costs to spiral. Are you tired of this wasteful headache that starts at the source?

The "Trust Gap" in Your Premium Promise: You market your product as "finely deboned," yet customer complaints about finding fine bones persist. Is this failure to deliver a 100% guaranteed promise holding you back from higher-value markets?

SameGram X-ray Inspection Solutions: Catch Foreign Contaminants Before They Become Costly Recall

The Purifier Solution for Bulk & Raw Materials

In food production, weight control is not Application: Deployed at the front of the line for all loose, unpackaged raw materials like grains, nuts and beans

Core Value: Eradicate contamination at the source. Before a foreign body can be broken down, mixed, and cause widespread contamination or equipment damage, our system identifies and removes it with a high-speed, precise rejection mechanism. This is your most cost-effective line of defense.

Solution: Bulk Goods X-ray Inspection Systems

Details

The Specialist Solution for Seafood Safety

Application: Purpose-built for seafood processing lines to detect fine bones in products like fish fillets and portions.

Core Value: Fulfill your "boneless" quality promise with absolute confidence. Using industry-leading low-energy X-ray imaging, it pinpoints minute residual bones that manual inspection can never guarantee, empowering your entry into premium restaurant, infant food, and other high-end markets.

Solution: Fish Bone X-ray Inspection System

Learn more

The Guardian Solution: Standard Inspection for Packaged Goods

Application: The essential final quality check for a wide variety of packaged goods (pouches, cartons, trays, etc.). Ideal for detecting common, dense contaminants and ensuring overall product integrity.

Core Value: This is your frontline defense and the workhorse of your production line. It provides robust, reliable protection against common foreign bodies like metal, glass, and stone, while also checking for basic packaging defects. It delivers a powerful combination of safety, reliability, and value, safeguarding your brand's reputation with every product you ship.

Solution: Standard X-ray Inspection System

more Details

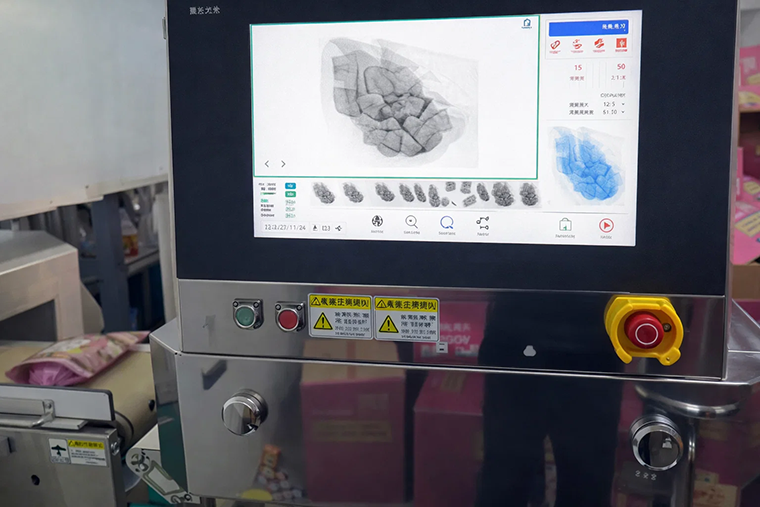

The Precision Guardian Solution: High-Definition Inspection

Application: Designed for complex products, premium goods, or challenging packaging formats (e.g., foil, multi-layered materials, irregular shapes). Essential for detecting low-density contaminants or performing intricate quality checks.

Core Value: When standard detection isn't enough, the Precision Guardian delivers uncompromising certainty. It utilizes advanced sensor technology and sophisticated software to find what others miss—including low-density plastics, rubber, and minute bone fragments within complex products. It is the definitive solution for brands that compete on superior quality and require the highest possible level of assurance.

Solution: High-precision X-ray Inspection System

read moreRecommended products

Provide the Most Suitable X-ray Inspection System Solution

Standard Machine for X ray Inspection Machine XSS series

- Offers the best balance of performance and value for common packaged goods.

- Engineered for simplicity and reliability, ensuring easy integration and stable operation.

- Effectively detects common, high-density contaminants like metal, glass, and stone.

High-precision X-ray Inspection Systems XSS Series

- Delivers superior accuracy to find smaller, low-density contaminants that standard systems miss.

- Performs advanced quality checks beyond contamination, such as identifying broken or missing items.

- Maintains high performance even with challenging packaging like foil or multi-layered materials.

Bulk Goods X-ray Inspection Systems XSS-S Series

- Uniquely designed to inspect loose, unpackaged, and flowing raw materials at the start of the line.

- Prevents widespread contamination by removing foreign bodies before they are processed and mixed.

- Uses a high-speed air-jet rejection system to minimize waste of good product.

Fish Bone X-ray Inspection System XSS-F-4610

- Hyper-specialized for one purpose: detecting fine, low-density pin bones in seafood.

- Utilizes advanced low-energy imaging to maximize the contrast between bone and flesh.

- Driven by intelligent algorithms trained specifically to identify bone structures and reduce false rejects.

Successful Cases

What Our Customers Say

- Packaged food X-ray inspection system

- automated x-ray inspection system

- x ray food inspection systems

- x-ray inspection machines

- food x-ray inspection systems

- industrial x ray inspection systems

- fish bone x-ray inspection system

- x-ray inspection systems ready meals

- poultry x-ray inspection system

- food x ray inspection machine

- bulk flow x-ray inspection systems

- x-ray inspection systems fish

- chicken bone x-ray inspection systems

- food and pharmaceutical x-ray inspection systems

- china x ray inspection system

- x ray inspection system for food

- x ray inspection machine

faq

Frequently Asked Questions

- Q:How accurate are X-ray inspection systems?Accuracy depends on energy, detector, and algorithms; dual-energy and AI improve material discrimination and lower false positives.

- Q:In which industries can Samegram's X-ray inspection systems bse used?SameGram X-ray inspection systems are designed for the food industry, including packaged, bulk, and seafood products, and can detect contaminants such as metal, glass, stones, bones, and hard plastics, ensuring product safety and quality.

- Q:Is investing in X-ray inspection worth it?X-ray inspection systems quickly pay for themselves by reducing recalls, cutting waste, and improving efficiency, delivering a strong ROI for food, pharma, and electronics manufacturers.

- Q:When should I use 3D/CT instead of 2D X-ray?Use 3D/CT for complex internal geometry, failure analysis, or precise metrology when 2D images aren’t sufficient.

- Q:What is an X-ray inspection system and how does it work?X-ray inspection machines should receive an annual technical inspection, with quarterly checks for high-volume lines, while daily basic checks help maintain stable performance and prevent issues.

- Q:Can the system be integrated with my production line?X-ray inspection systems can be integrated with production lines, supporting PLC/MES control, automatic reject mechanisms, and data reporting for seamless quality control.

Ready to Build Your Own Solution?

Choosing SameGram means

Flexible customization

Perfectly adapt to existing systems

Rich experience

16 years of professional manufacturing precipitation

Free samples

Support remote viewing and sample testing

Fast delivery

standard products in stock, shipped on the same day

Extensive verification

5000+ customers trust, wide industry coverage

After-sales guarantee

2-year warranty, lifetime maintenance

- ASK SameGram

- Contact SameGram

- Metal Detector Checkweigher Selection Table

- Checkweigher Selection Registration Form

- Labeling technical parameters

- Phone

- Phone

- Phone

- Phone

- Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions