Industrial Metal Detectors: Buying Guide & Selection Tips

Welcome to this comprehensive guide on purchasing an industrial metal detector. As a critical tool for detecting metal contaminants in products, ensuring compliance with safety regulations, and protecting consumers in industries like food and pharmaceuticals, choosing the right metal detector can significantly impact your production efficiency and product quality. At SameGram, with over 20 years of expertise in developing high-precision inspection equipment, we specialize in creating reliable metal detection solutions that integrate seamlessly into automated lines. Our systems have been trusted in more than 120 countries, delivering over 5,000 units to enhance safety and efficiency. This guide draws from industry best practices to help you make an informed decision, while highlighting how our customizable solutions can address your specific needs.

Industrial metal detectors are essential for identifying metal impurities—such as ferrous, non-ferrous, and stainless steel fragments—that could contaminate products and violate regulations. In the food and pharmaceutical sectors, undetected metals can lead to costly recalls, health risks, and reputational damage. By implementing a robust detection system, you can prevent these issues, reduce waste, and ensure consistent quality.

At SameGram, our metal detectors are designed to detect contaminants with high accuracy, even in challenging environments. For instance, our systems use multi-frequency signal processing to minimize false alarms and achieve detection levels suitable for various product types, helping businesses like food processors reduce false rejects by up to 85% and improve accuracy to 99.8%, as seen in real-world applications.

Key benefits include:

● Contaminant Prevention: Safeguards against metal fragments from machinery or raw materials.

● Regulatory Compliance: Meets standards like HACCP and ISO22000, ensuring export-ready products.

● Efficiency Gains: Integrates with production lines to maintain high speeds without downtime.

If you're experiencing frequent false alarms or integration issues, our free sample testing service can verify compatibility—contact us for a no-obligation assessment.

Understanding Types of Industrial Metal Detectors

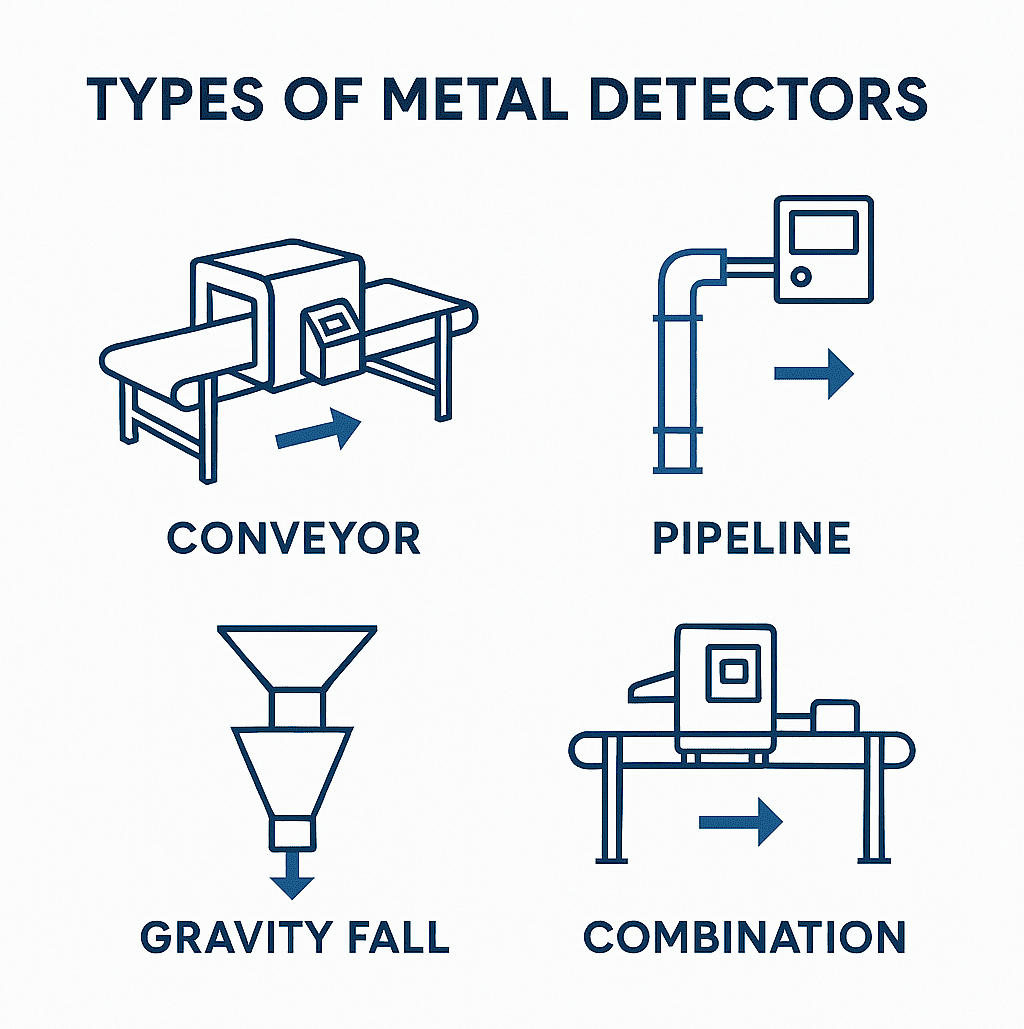

Selecting the right type depends on your product format and production setup. Common types include:

● Conveyor Belt Metal Detectors: Ideal for packaged goods on assembly lines. These systems scan products as they move along a belt, making them suitable for high-volume operations in food and pharma.

● Pipeline Metal Detectors: Best for liquids, pastes, or pumped materials, ensuring detection in enclosed flows without disrupting production.

● Gravity Fall (Free Fall) Metal Detectors: Perfect for bulk powders and granules, detecting contaminants as materials fall through the system.

● Combination Systems: Merge metal detection with other inspections, like checkweighing, for comprehensive quality control.

At SameGram, we offer a range of these types for your model selection, such as our End of Line Conveyor Metal Detector DD-360 and Conveyor Metal Detector DD-390, which feature modular designs for easy customization. Our free fall detectors, like the Gravity Fall Metal Separator HC-700, handle bulk materials with channel dimensions optimized for efficiency, providing high sensitivity across ferrous, non-ferrous, and stainless steel contaminants. These are built with IP65-rated protection for durability in dusty or wet environments, addressing common pain points like environmental interference.

Key Factors to Consider When Purchasing Industrial Metal Detectors

To avoid costly mistakes, evaluate these essential factors based on your operational needs:

1. Sensitivity and Detection Capabilities

Sensitivity determines how small a contaminant the detector can identify. It must handle ferrous (easiest to detect), non-ferrous, and stainless steel (most challenging, especially in wet or salty products). Factors like product orientation and environmental noise can affect performance—opt for systems with auto-adjusting frequencies to maintain stability.

SameGram's detectors excel here, with our dual-frequency and high-frequency technologies ensuring reliable detection even in foil-sealed products. For example, our systems incorporate interference suppression to achieve high accuracy without frequent recalibration, solving issues like temperature drifts that plague less advanced models.

2. Aperture Size and Product Compatibility

The aperture (opening) must fit your largest product while maintaining optimal sensitivity—larger apertures reduce detection precision. Consider product characteristics: wet, salty, or foil-packaged items can create "product effects" that mimic metals, leading to false rejects.

Our customizable apertures in the High Precision Conveyor Metal Detector DD-390 Series allow for tailored fits, supporting widths up to 400mm, heights up to 120mm, and speeds up to 1000m/min, fixed speed 25m/min, ensuring compatibility with diverse products from baked goods to pharmaceuticals.

3. Environmental Durability and Hygiene

Harsh conditions like humidity, dust, or temperature fluctuations can cause electronic drift. Look for IP-rated enclosures (e.g., for washdowns) and stable components to ensure longevity.

SameGram's stainless steel constructions meet GMP standards, with features like tool-free cleaning and environmental simulation testing in our 4000+ m² factory. This ensures our detectors withstand high-pressure cleaning, ideal for food and dairy lines.

4. Integrate the Metal Detector with Production Lines

Seamless integration minimizes downtime. Ensure compatibility with conveyors, reject mechanisms, and upstream/downstream equipment like checkweighers.

We specialize in combination metal detection systems, integrating metal detectors with our high-speed checkweighers (e.g., Checkweigher with Metal Detector Combination System SCM-4530L2 at 5-28m/min), offering modular upgrades for smart factories. Our onsite installation and commissioning services handle everything from deployment to operator training.

5. Regulatory Compliance and Testing

Compliance with FDA, USDA, or HACCP is non-negotiable. Systems should include automated testing protocols and documentation for audits.

SameGram detectors come with IQ/OQ/PQ protocols and certifications like CE and ISO9001, supporting full traceability. Regular validations, as part of our preventive maintenance plans, help you meet global standards effortlessly.

6. Maintenance and Long-Term Reliability

Choose user-friendly systems with diagnostic tools, easy access for cleaning, and strong support. Automated monitoring reduces manual checks and predicts failures.

With a 12-month warranty and lifetime technical support, SameGram provides remote diagnostics via cloud services and spare parts supply. Our multi-stage quality control (IQC, PQC, FQC) ensures devices last, backed by over 16 years of OEM/ODM experience.

Common Precautions of Metal Detector Conveyor Systems

● Overfocusing on Sensitivity Alone: Without stability, high sensitivity leads to false alarms. Test in real conditions.

● Ignoring Integration Risks: Poor fit causes downtime—conduct site audits.

● Neglecting Hygiene Needs: Non-washdown models fail in food environments.

● Underestimating Costs: Factor in ROI from reduced recalls and efficiency gains.

● Skipping Supplier Evaluation: Choose partners with proven support, like SameGram's global 72-hour response.

Our R&D team addresses these through testing and troubleshooting, ensuring your system solves real problems.

Customizable metal detector for conveyor belt with dual frequency, high sensitivity, and strong anti-interference.

Categories: Conveyor Metal Detector

Brand: SameGram

Model: DD-390 Series

Sensitivity (empty belt surface): FE(Φ0.8mm),NON-FE(Φ1.2mm),SUS316(1.5Φmm)

Production speed: 1~1000m/min, fixed speed 25/min

Effective detection channel(mm): 400 ×120 (W×H) customizable

Conveyor belt material: Food-grade PU belt

Structure: SUS304, Comply with HACCP, GMP, FDA, CAS, and other

Protection: IP 66 (probe), others are IP54, optional

Step-by-Step Metal Detector Buying Process

1. Assess Risks: Audit your line for contamination sources.

2. Define Specs: Match type, sensitivity, and features to needs.

3. Test and Demo: Use supplier trials—SameGram offers free onsite demos.

4. Budget and ROI: Calculate savings from waste reduction.

5. Install and Train: Ensure smooth rollout with expert support.

6. Maintain: Schedule regular checks for ongoing performance.

Conclusion: Choose SameGram for Reliable Metal Detection

Investing in the right metal detector safeguards your products and boosts efficiency. At SameGram, our intelligent solutions—backed by a dedicated R&D team, certified factory, and proven track record—deliver customized, high-performance systems. Whether for food safety or pharma compliance, we're your partner in automation.

Ready to upgrade? Visit our Metal Detector Page or request a quote at Contact Us. Experience the SameGram difference today!