Checkweigher Market 2025: High-Precision Analysis & Growth Trends

Welcome to our comprehensive guide on the Automatic Checkweigher Market. As a leading provider of intelligent weighing solutions, SameGram specializes in dynamic checkweighers designed to ensure product weight compliance during factory production processes. Whether you're in the food, pharmaceutical, or logistics industry, understanding the market dynamics and implementing reliable checkweigher technology can help you meet regulatory standards, reduce waste, and boost efficiency. In this article, we'll explore market trends, key benefits, and how SameGram's innovative products can solve your real-world challenges.

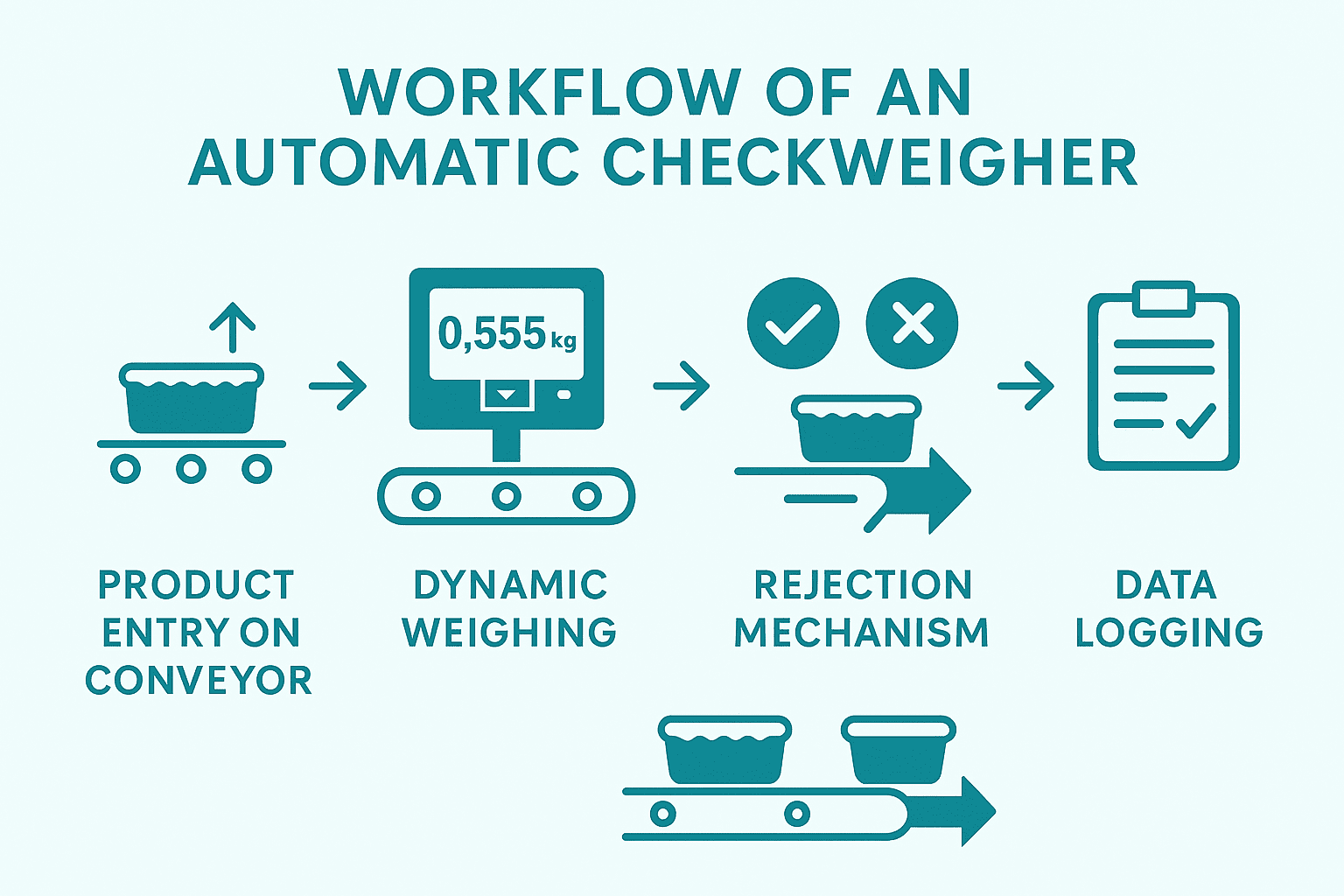

What is a Dynamic Checkweigher and Why Does It Matter?

A dynamic checkweigher is an automated weighing system used in manufacturing to verify that products meet specified weight requirements. It operates dynamically, weighing items in motion on a conveyor belt without halting production. This ensures compliance with design specifications and regulations, particularly in industries like food and beverages, where underweight or overweight products can lead to recalls, fines, or consumer dissatisfaction.

For instance, in food production, a checkweigher machine detects deviations in packaged goods—such as snacks or beverages—rejecting non-compliant items in real-time. This not only maintains quality but also minimizes giveaway (overfilling) and waste, directly impacting your bottom line. Common problems it solves include:

● Regulatory Compliance: Adhering to standards like FDA, USDA, or EU guidelines to avoid penalties.

● Production Efficiency: High-speed inspection (up to 300 pieces per minute) prevents bottlenecks.

● Cost Savings: Reducing material overuse and rework by ensuring precise weights.

By integrating a checkweigher scale, businesses can achieve up to 99.9% accuracy, enhancing traceability and customer trust.

Automatic Checkweigher Market Overview

The Automatic Checkweigher Market is experiencing steady growth, driven by the rising demand for automation, stringent quality controls, and the expansion of packaged goods industries. According to recent reports, the market was valued at approximately USD 436.9 million in 2023 and is projected to reach USD 635.5 million by 2032, growing at a CAGR of 4.2%. Other analyses forecast even higher growth, with the market reaching USD 701.6 million by 2032 at a CAGR of 9.6%, fueled by advancements in AI and IoT integration.

Key Market Drivers and Trends

● Automation Demand: Industries are adopting in-line checkweighers for real-time data analysis and predictive maintenance, integrating with Industry 4.0 technologies.

● Regulatory Pressures: Stringent food safety laws and labeling requirements in sectors like food & beverages and pharmaceuticals are major drivers, with the food industry holding over 35% market share.

● Technological Advancements: Trends include cloud-based monitoring, machine vision, and combination systems (e.g., with metal detectors), improving accuracy to ±0.02g.

● Growth in Emerging Markets: Asia-Pacific leads with the highest CAGR, driven by industrialization in China and India, while North America and Europe focus on compliance and efficiency.

Market Challenges and Opportunities

Challenges include high initial costs and integration complexities, but opportunities abound in AI-driven systems and sustainable practices, with the market expected to hit USD 1.44 billion by 2031 at a 4.9% CAGR. For businesses, this means investing in scalable checkweighers to stay competitive.

Segment | Key Insights | Growth Projection | ||

| By Type | In-motion/dynamic checkweighers dominate for high-speed lines; combination systems growing fastest. | CAGR up to 6.5% for dynamic types. | ||

| By Capacity | Medium (100-500 kg) holds the largest share; high-capacity for logistics. | Up to 60 kg segment growing at 5.5% CAGR. | ||

| By End-Use | Food & Beverages (largest); Pharmaceuticals (fastest-growing). | Food sector: 35%+ share; Pharma: Driven by GMP compliance. | ||

| By Region | Asia-Pacific (35%+ share); North America (mature market). | APAC: Highest growth due to packaging boom. | ||

How Checkweigher Combination Systems Solve Real-World Problems

Implementing a checkweigher combination system addresses practical issues in production:

1. Weight Verification: Automatically rejects under/overweight items, ensuring every product meets specs (e.g., ±0.02g accuracy for small packages).

2. Waste Reduction: Prevents overfilling, saving materials—potentially reducing costs by 5-10% in high-volume lines.

3. Compliance and Traceability: Logs data for audits, supporting regulations like FDA or EU standards.

4. Integration Ease: Modular designs fit existing lines, with options for metal detection or labeling.

5. High-Speed Operations: Handles 50-300 packs/min, ideal for fast-paced environments without downtime.

For example, in a food factory, a checkweigher can inspect bottled beverages at 120 m/min, diverting defects and exporting data for quality reports.

Discover SameGram: Your Trusted Partner in Inline Checkweigher Solutions

At SameGram, we bring over years of expertise in industrial automation weighing, with a mission to deliver accurate, efficient, and reliable systems. As a high-tech enterprise with more than 5,000 success stories, we specialize in inline checkweighers for food, pharmaceuticals, logistics, and cosmetics. Our High-Precision and Ultra-Fast Checkweigher stands out with features like:

● Accuracy: ±0.02g to ±10g, certified to MID and ISO standards.

● Speed: Up to 300 pieces/min, with belt speeds of 5-120 m/min.

● Hygiene: Stainless steel, flushable design meeting GMP requirements.

● Customization: Modular integration with rejection systems and data logging.

This product solves key pain points by enhancing efficiency, ensuring compliance, and reducing waste—perfect for upgrading your production line. Visit our product page for specs or contact us for free sample testing and custom solutions.

Hot-sale Related Checkweighers

SCP6 is a dynamic checkweighing system for small packages. it supports multi-lane control, fast data export and GMP compliance.

SC1-H-3512L1 is a high precision checkweigher designed for production line with high precision needs like pharmaceuticals

WSS-5012L2 is a compact weight sorter machine designed to ensure stable output and quality control. ideal for fish and meat.

SBW-2512B12 is a multi head combination weigher ideal for fast, precise dosing,also known as linear combination scale.

SCL-7035L5 is a weigh price labeler that integrates a weighing machine with label printer(s),which is very widely used