Roller Dynamic Checkweigher for Large Packages | SC3-10060L30

SC3-10060L30 is an Dynamic Roller Checkweigher for large packages, economical and widely used in various outer box products

Detail Information

Detail Information

Roller Dynamic Checkweigher for Large Packages | SC3-10060L30

Introduction

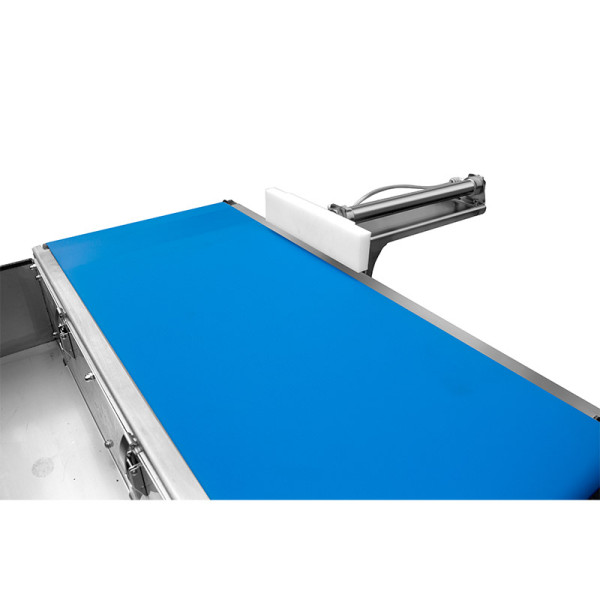

The SC3-10060L30 Roller Dynamic Checkweigher is an automatic checkweigher machine designed for medium-weight cartons and large packages. Its fully roller-based weighing and conveying sections make it durable, easy to clean, and ideal for high-volume production lines where precision requirements are moderate.

This inline conveyor scale ensures smooth and efficient weight inspection, helping operators quickly identify missing items or underweight packages. The roller design offers long-lasting performance at a reasonable cost while supporting a variety of industries, including food, pharmaceuticals, electronics, and daily chemicals. With seamless integration into existing checkweigher systems, SC3-10060L30 provides reliable real-time monitoring and can be connected to ERP/MES systems for streamlined operations.

Compact, robust, and easy to maintain, it is a practical solution for companies seeking an efficient checkweigher for large packages without overcomplicating their production line.

Roller Dynamic Checkweigher for Large Packages | SC3-10060L30 Features

Roller Dynamic Checkweigher for Large Packages | SC3-10060L30

Technical Parameters

| Product model | SC3-10060L30 | |

| Weighting range | 1-30kg | |

Weighting section size | L 1000mm*W 600mm | |

Belt speed | 5-60m/min | |

Air pressure interface | Φ8mm | |

| Case material | Spray painting on carbon steel | |

Conveying direction | Facing the machine, left in and right out | |

Display division | 10g | |

| Weighting accuracy | ±15-30g | |

| Applicable product size | L≤750mm; W≤600mm | |

Storage formula | 100 types | |

| Power supply | AC220V±10% | |

| Air source | 0.5-0.8MPa | |

Data transmission | USB data export | |

Alarm mode | Sound and light alarm and automatic rejection | |

Rejection mode | Push rod type, swing wheel type, jacking transplanting are optional | |

| Optional function | Real-time printing, code reading and sorting, online code spraying, online code reading, online labeling | |

Operation screen | 7-inch Kunlun Tongtai color touch screen | |

Control system | Samegram online weighing control system V1.0.5 | |

| Other configurations | Mean Well power supply, Jingyan motor, stainless steel roller, AVIC electrical sensor | |

* The maximum checkweighing speed and accuracy may vary depending on the actual product being tested and the installation environment.

* When selecting the model, pay attention to the direction of product movement on the conveyor belt. For transparent or semi-transparent products, please contact our company.

* When selecting the model, pay attention to the direction of product movement on the conveyor belt. For transparent or semi-transparent products, please contact our company.

Available Rejection Systems for Roller Dynamic Checkweigher SC3-10060L30

The heavy-duty pusher rejector pair with checkweigher systems to deliver accurate, mid-speed removal of heavy, boxed items.

Roller pusher rejector system for fully removing defective hard-packed and boxed products from roller conveyors.

Fast swing arm works with checkweigher or metal detector systems to remove defective boxes and bags up to 1 kg.

File Downloads

For more product related parameter files, please contact us.

Roller Dynamic Checkweigher Weighing for Diverse Products Industry Applications

The Roller Dynamic Checkweigher is engineered for accurate inline weighing and classification of large cartons, bags, boxes, and bulk packages. It is widely adopted in several high-demand industrial sectors, including:

Bulk cartons containing bottled milk, yogurt multipacks, butter cartons, or egg trays often vary in internal load distribution.

The roller dynamic checkweigher ensures:

· Accurate final-case verification for export or retail distribution

· Stability when weighing liquid or semi-liquid dairy products that may shift inside the box

· Reliable detection of underweight cartons caused by missing items or packing deviations

· Full data recording for traceable quality control in dairy processing plants

This makes it a strong match for chilled-product packaging lines, warehouse dispatch areas, and end-of-line QC stations.

Large-volume dry food producers often pack rice, grains, cereals, flour bags, or assorted dry-food items into master cartons.

The checkweigher supports:

· Consistent dynamic weighing even for dense or irregularly filled boxes

· Real-time detection of missing bags or partially filled inner packs

· Smooth roller conveying suited for heavy, high-density cartons

· Automatic classification or alarm based on preset weight ranges

Suitable for grain mills, cereal factories, international distributors, and warehouse fulfillment centers.

For beverages, snacks, sauces, and general packaged foods, carton weight accuracy affects shipping cost, customer experience, and regulatory labeling.

The system provides:

· High stability for multi-bottle, multi-can, or multi-pouch cartons

· Reliable operation in environments with temperature or humidity fluctuations

· Fast product recipe switching for mixed product lines

· Integrated statistical reporting for QA teams

This makes it ideal for factories with a broad SKU range or frequent product changeovers.

Electronics and Toys manufacturers require high-accuracy carton verification to prevent shortages, expensive returns, and compliance disputes.

The checkweigher is widely used for:

· Boxed electric tools, small appliances, accessory kits

· Toy sets, model kits, and multi-component packs

· Inline verification before sealing or palletizing

· Recording weight profiles for traceable assembly lines

The roller structure supports fragile, heavy, or rigid-box items without belt deformation, ensuring consistent weighing performance.

As a key part of logistics automation, the checkweigher helps warehouses and distribution centers optimize process accuracy and reduce manual checking.

It is commonly used for:

· Outbound parcel weight confirmation

· Carton classification by weight segment

· Preventing shipping-cost discrepancies

· Real-time data upload to WMS or ERP systems

· High-throughput carton handling with durable roller structure

Its robustness and simple mechanical design make it ideal for multi-shift continuous operation.

Roller Dynamic Checkweigher for Large Packages Case studies

Why Choose Our Roller Dynamic Checkweigher

15+ Years of Inline Weighing Innovation

We specialize in dynamic weighing, sorting, and intelligent inspection systems with global customer installations across heavy-package industries.

Deploy Fast, Operate Easily, Perform Reliably

· Roll-on dynamic weighing for large packages

· Simple HMI recipe switching

· Flexible IO configurations for full automation

· Immediate integration into existing conveyor systems

Built for Durability & Long-Term Stability

· Full stainless-steel construction

· High-stability load-cell weighing module

· Multi-level authorization + complete logging system

· One-year warranty with technical support

· Optional customization for specialized package dimensions

Roller Dynamic Checkweigher Technical Overview & System Capabilities

Proven Mechanical Structure

With over 15 years of engineering experience in dynamic weighing, the checkweigher features:

· High-rigidity stainless-steel frame

· Precision load-cell weighing module

· Non-powered roller conveyor design for heavy cartons

· Stable structure minimizing vibration and measurement error

These ensure long-term reliability and durability even under demanding environments.

High-Accuracy Dynamic Weighing System

· Dynamic compensation algorithms

· Adjustable weighing thresholds

· Support for up to 20 product recipes

· Customizable infeed/outfeed delay, compensation values, and sampling time

· Smooth weighing display with adjustable division values and decimal precision

This allows the system to handle varied package sizes and speeds with consistent results.

Advanced HMI + Multi-Level User Management

· Intuitive touchscreen interface

· Operator / Supervisor / System Administrator permissions

· Password management, factory information entry, expiry-date shutdown protection

· Real-time statistical reports + historical data filtering

U-disk data export (overwrite or append)

Comprehensive IO & Automation Integration

Supports flexible automation layouts:

· Multiple photocell modes (dual, in, out, non-photocell)

· External start/stop buttons: level or pulse trigger

· Alarm-clearing IO

· Output functions including reject actions, fail alarms, overflow alarms

· Input functions: start, stop, photocell detection, full detection, alarm reset

This enables seamless connection with packaging lines, diverters, conveyors, and PLC systems.

Roller Dynamic Checkweigher Installation & Operational Recommendations

Installation Requirements

· Keep away from vibration sources and strong airflow

· Ensure the weighing platform is level

· All four adjustable feet must bear equal load

· Proper grounding and correct power supply connection

· Calibration is required after installation

· Remove transport safety screws before operation

Operating Safety Tips

· Do not open the electrical cabinet without authorization

· Avoid water splashing onto electrical components

· Do not place unrelated objects on moving or rolling mechanisms

· Press the emergency stop button immediately if abnormal activity occurs

· Follow correct maintenance intervals for sensors, rollers, and mechanical parts

Roller Dynamic Checkweigher for Large Packages FAQs

Q. Can this checkweigher handle heavy cartons or large-size packages?

Yes. The roller structure is specifically designed for large cartons, bulky bags, and oversized items that standard belt checkweighers cannot handle.

Q

.

Does dynamic weighing remain accurate on uneven packages?

Dynamic compensation algorithms ensure stable results as long as the package has a stable contact with the rollers.

Q. Can the device integrate with my existing conveyor system?

Yes. The system supports flexible IO, external PLCs, and MES/WMS integration.

Q. Can I export weighing data for traceability?

Yes. Weight records can be viewed in the report module and exported to a U-disk in multiple data formats.

Q. What maintenance is required?

Avoid water contact with electrical parts, check roller wear regularly, and ensure routine calibration for optimal accuracy.

Review

- Loading...

Related Products

Please Contact Our Specialists at Any Time

- ASK SameGram

- Mobile Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions