High-Speed Dynamic Weighing Scale for Parcel Logistics SC3-L-12080S60

SC3-L-12080S60 is one of the best parcel weighing scales for large-items up to 60kg.,which can be integrated into DWS system.

Detail Information

Detail Information

High-Speed Dynamic Weighing Scale for Parcel Logistics SC3-L-12080S60

Introduction

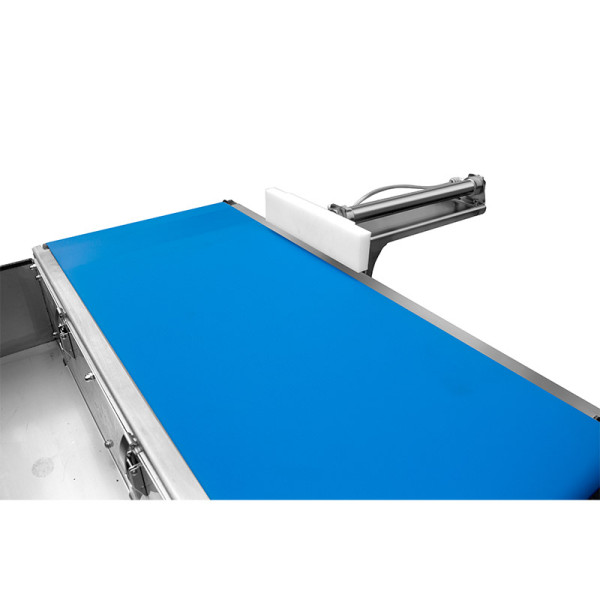

The SC3-L-12080S60 is a high-speed dynamic weighing scale designed for logistics operations, capable of handling parcels from 1 to 60 kg with up to ±30g precision. Its wide belt and robust platform accommodate bulky or irregular packages while maintaining fast throughput of up to 120 m/min.

Primarily built for weighing parcel logistics, this system ensures accurate weigh out logistics for distribution centers, freight hubs, and industrial shipping lines. It integrates seamlessly with scanners and sorters, simplifying large-scale workflows and improving efficiency.

Although the standard configuration does not include an automated rejection system, the SC3-L-12080S60 can be customized as a checkweigher for applications that require automatic removal of overweight or underweight parcels, providing flexible solutions for diverse logistics needs.

High-Speed Dynamic Weighing Scale for Parcel Logistics SC3-L-12080S60 Features

High-Speed Dynamic Weighing Scale for Parcel Logistics SC3-L-12080S60

Technical Parameters

| Product model | SC3-L-12080S60 | |

| Weighting range | 1-60kg | |

Weighting section size | L 1200mm*W 800mm | |

Belt speed | 5-120m/min | |

Case material | Carbon steel spray painting | |

Display division | 1g | |

| Weighting accuracy | 10-30g | |

| Applicable product size | L≤800mm; W≤800mm | |

Storage formula | 1 type | |

| Power supply | AC220V±10% | |

Data transmission | USB data export | |

Sorting section | Standard 1 section | |

Rejection mode | Push rod type, lever type, balance wheel optional | |

| Optional function | Real-time printing, code reading and sorting, online code spraying, online code reading, online labeling | |

Operation screen | 7-inch Kunluntong color touch screen | |

Control system | Samegram online weighing control system V1.0.5 | |

Other configurations | Meanwell power supply, Jingyan motor, Swiss PU food conveyor belt, NSK bearing, Mettler Toledo sensor | |

* The maximum checkweighing speed and accuracy may vary depending on the actual product being tested and the installation environment.

* When selecting the model, pay attention to the direction of product movement on the conveyor belt. For transparent or semi-transparent products, please contact our company.

* When selecting the model, pay attention to the direction of product movement on the conveyor belt. For transparent or semi-transparent products, please contact our company.

Available Rejection Systems for Dynamic Weighing Scale SC3-L-12080S60

This is a high-speed wheel sorter conveyor for logistics. offering reliable and accurate diversion in warehouse operations.

The heavy-duty pusher rejector pair with checkweigher systems to deliver accurate, mid-speed removal of heavy, boxed items.

Roller pusher rejector system for fully removing defective hard-packed and boxed products from roller conveyors.

File Downloads

For more product related parameter files, please contact us.

High‑Speed Dynamic Weighing Scale Industry Applications

Our High-Speed Dynamic Weighing Scale for Parcel Logistics is engineered for today’s fast-paced warehousing and logistics fulfillment environment, where high accuracy and continuous flow operations are essential. As a core module in DWS weighing & scanning systems, it supports:

Parcel Sorting Centers

Inline dynamic weighing of parcels, polybags, envelopes, and cartons, enabling real-time weight verification, automated classification, and integration with barcode scanning or RFID systems.

E-commerce Fulfillment Warehouses

Supports automated packing stations and outbound quality checks by providing precise weight data to WMS/OMS platforms, preventing mis-shipments and reducing return losses.

Courier and Express Distribution Hubs

Ideal for belt-to-belt weighing in high-throughput environments where parcels vary in size, shape, and material. The fast dynamic capture ensures minimal gap times and smooth flow.

3PL & Cross-Border Logistics Providers

Often used as part of dimensioning + weighing + labeling solutions, ensuring carriers bill correctly based on actual weight and preventing manual errors.

High‑Speed Dynamic Weighing Scale Applications

High‑Speed Dynamic Weighing Scale Technology Overview & Performance Analysis

The SC3-L-12080S60 is built using the latest dynamic weighing, signal filtering, and motor control technologies, ensuring industry-leading stability and accuracy.

Precision Weighing Architecture

· High-stability load cell with optimized mounting structure reduces vibration impact.

· Photoelectric sensors detect parcel entry/exit for synchronized weighing.

· Intelligent filtering algorithm (adjustable strength & coefficient) maintains accuracy even during high-speed movement.

· Dynamic compensation corrects weight deviation based on conveyor speed and parcel characteristics.

Flexible Multi-Speed Control

Three independent motors—infeed, weighing conveyor, and sorting conveyor—allow custom speed programming to match your line’s throughput.

Supports:

· Analog voltage control

· RS485 Modbus RTU for VFD control (frequency & start/stop registers)

Advanced HMI System

A full-featured touchscreen operation panel includes:

· Recipe management (100 sets) for multi-product logistics workflows

· User management with Admin/System/User roles

· Zero-tracking, overload protection, stability indicators

· Real-time statistics, history data, and USB data export

· IO mapping for external triggers, sorters, labelers, printers, or PLC systems

Ready for System Integrators

· The scale is purposely designed for integrators who build checkweighing + barcode scanning, DWS, or parcel labeling systems.

· All components — including IO ports, communication modes, and motor control — · follow open industry standards.

High‑Speed Dynamic Weighing Scale Installation

Installation Requirements

Install on a stable, vibration-free surface

Ensure machine is properly grounded

Remove the shipping support bracket before operation

Avoid high-humidity or high-temperature environments

Electrical & Safety Guidelines

Confirm input voltage matches device rating

Electrical wiring must be performed by trained technicians

Do not open the control cabinet without authorization

Avoid washing electrical components with water or corrosive liquids

System Integration Tips

Use dedicated power lines (avoid long, thin extension cords)

Configure IO functions for start/stop, photoelectric signals, rejecters, and alarms

Set proper speed, delay time, and compensation values for the parcel type.

Use calibrated standard weights for load cell calibration

For DWS systems, maintain consistent parcel spacing for optimal detection

High‑Speed Dynamic Weighing Scale FAQs

Q1: What types of parcels can this dynamic weighing scale handle?

A: It supports cartons, polybags, envelopes, irregular parcels, and most logistics items under the rated capacity.

Q2: Can the scale be integrated with barcode scanners or dimensioners for a DWS system?

A: Yes. It is widely used by integrators to build DWS systems using external scanners, cameras, or dimensioners.

Q3: How accurate is the dynamic weighing at high speed?

A: Accuracy varies by parcel size, belt speed, and conveyor conditions, but the system is engineered for consistent performance in high-throughput logistics environments.

Q4: Does it support data export?

A: Yes. It supports USB export, historical record queries, and integration via RS485 or IO.

Q5: How many recipes can I store?

A: Up to 100 recipes, allowing operators to switch quickly between different parcel categories or sorting rules.

Review

- Loading...

Related Products

Please Contact Our Specialists at Any Time

- ASK SameGram

- Mobile Phone

- Product Finder

Quickly filter to find the product you want

- Inventory Machines

Short delivery time and quick installation

- Free Test Piece

Confirm after sensitivity test

- Customization Support

Inspiring customized solutions