What is a Checkweigher Metal Detector Combination System?

Ensure Product Safety and Quality with SameGram's Advanced Dynamic Checkweigher and Metal Detector Solutions

A dynamic checkweigher metal detector combination system is a cutting-edge, integrated solution designed to streamline quality control in food and pharmaceutical production lines. By combining an Industrial metal detector and a dynamic checkweigher into a single compact unit, this system simultaneously verifies product weight and detects metal contaminants, ensuring compliance with safety standards and minimizing waste. At SameGram, our SCM-4530L2 Checkweigher with Metal Detector Machine Combination System delivers precision, efficiency, and reliability, making it an ideal choice for manufacturers seeking to enhance product safety and protect their brand.

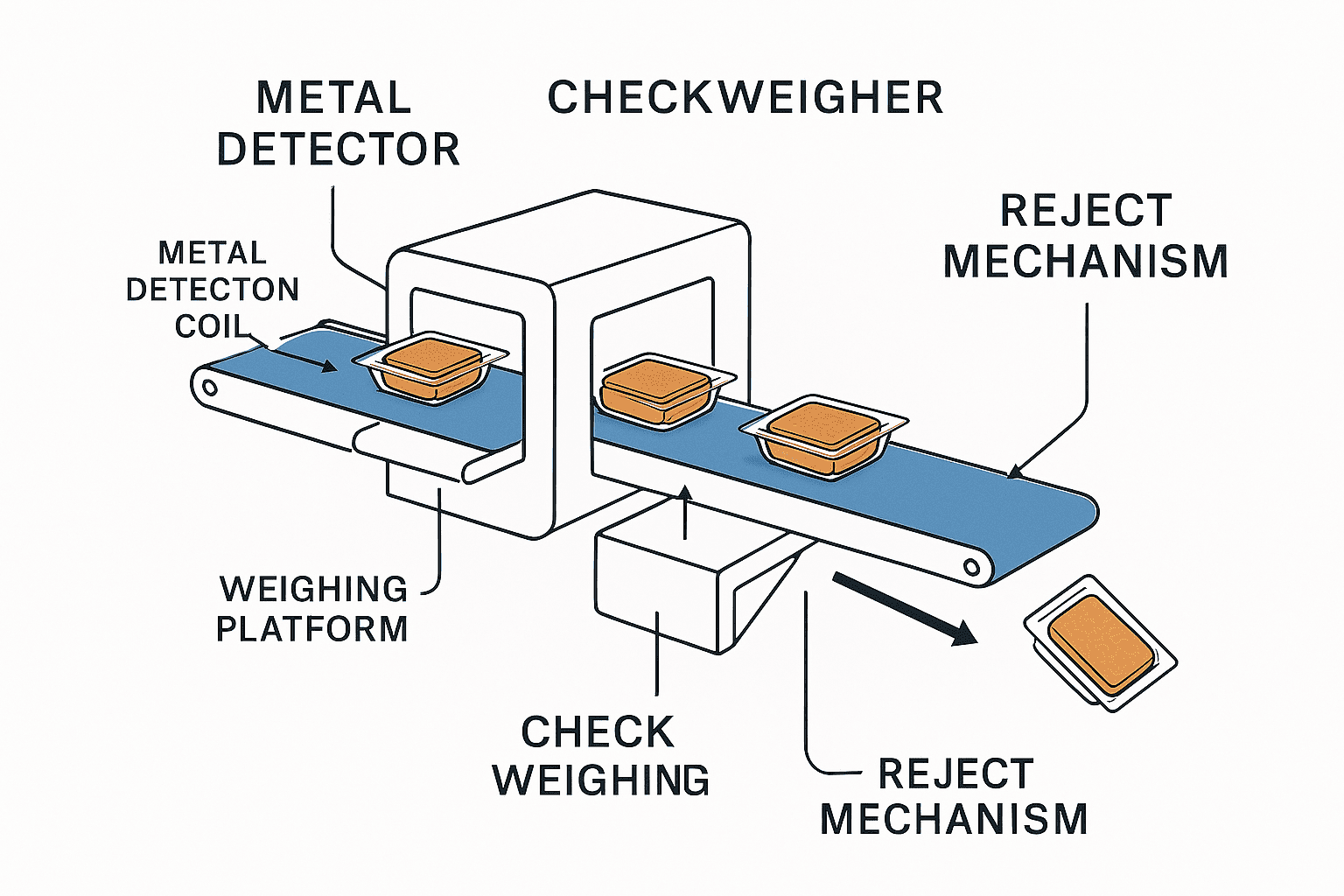

An in-line checkweigher metal detector combination system is an advanced inspection tool that integrates two critical functions:

1. Metal Detection: Utilizes electromagnetic induction to identify ferrous, non-ferrous, and stainless steel contaminants in products, ensuring food safety by preventing metal fragments from reaching consumers.

2. Checkweighing: Measures the weight of each product to ensure it meets specified tolerances, reducing overfills or underfills and minimizing product giveaway.

This dual-inspection system operates on a single conveyor, saving valuable production space and simplifying operation. It is widely used in industries like food processing, pharmaceuticals, and packaged goods to meet stringent regulatory standards such as HACCP, GFSI, and retailer requirements.

At SameGram, our expertise in precision engineering shines through in the Checkweigher with Metal Detector Combination System SCM-4530L2, a high-performance combination system designed for seamless integration into compact production lines. With over a decade of experience in manufacturing inspection equipment, SameGram ensures your products are safe, compliant, and consistent.

How Does an In-Motion Checkweigher Metal Detector Combination Work?

The system combines two technologies for efficient, real-time quality control:

Metal Detection Process

1. A metal detector uses inductor coils to generate a magnetic field. When a metal contaminant (e.g., ferrous, non-ferrous, or stainless steel) passes through, it creates eddy currents that disrupt the magnetic field, triggering an alert.

2. Advanced multi-frequency scanning, as used in SameGram’s SCM-4530L2, enhances sensitivity, detecting even small metal particles (e.g., Fe: 0.6-1.2mm, Non-Fe: 0.8-1.5mm, Sus: 1.2-2.0mm) across various product types, including high-moisture or conductive foods.

Checkweighing Process

1. The in-motion checkweigher measures product weight with high precision (e.g., ±0.3-1g for the SCM-4530L2) using a digital weighing sensor.

2. Products outside the acceptable weight range are automatically rejected, ensuring compliance with weight regulations and reducing costly giveaways.

Integrated Operation

Both functions are controlled via a single touchscreen interface, simplifying setup and operation. The SCM-4530L2 features independent reject mechanisms (push rod or sliding type) to separate metal-contaminated products from weight-noncompliant ones, improving sorting accuracy and traceability.

Key Benefits of a High Speed Checkweigher Metal Detector Combination System

Combining a metal detector and high-speed checkweigher into one system offers numerous advantages for manufacturers. Here’s why the SameGram SCM-4530L2 stands out:

Space-Saving Design

1. By integrating both functions into a single unit, the SCM-4530L2 saves up to 50% of production line space compared to separate systems, ideal for compact facilities.

2. Its sleek, stainless steel construction (304 grade) ensures durability and hygiene in demanding environments.

Enhanced Productivity

A single touchscreen interface simplifies operation, reducing training time and operator errors. The SCM-4530L2 Checkweigher Combination System supports multilingual controls and stores up to 100 product formulas for quick changeovers.

Cost Efficiency

Shared hardware reduces costs compared to purchasing standalone metal detectors and checkweighers. The SCM-4530L2’s integrated design also lowers maintenance expenses, with a single point of contact for service and support.

Superior Safety and Compliance

1. Detects a wide range of metal contaminants, including hard-to-detect stainless steel, ensuring compliance with food safety standards.

2. Precise checkweighing (±0.3-1g accuracy) minimizes product giveaway, saving costs while meeting regulatory requirements.

Easy Maintenance

Designed for quick troubleshooting and minimal downtime, the SCM-4530L2 Checkweigher Combination System features a hygienic, washdown-ready (IP65) design, perfect for food and pharmaceutical environments.

Smart Data Integration

Real-time data export via USB and compatibility with MES/ERP systems ensure full traceability, making audits seamless.

Applications of Automatic Checkweigher Metal Detector Combination Systems

The SameGram SCM-4530L2 Metal Detector Combination System is versatile, catering to a wide range of industries and product types. Its compact design and high sensitivity make it ideal for:

Food Processing

● Meat & Poultry: Detects metal in packaged cuts, sausages, or marinated products while verifying weight.

● Seafood: Ensures fillets, shrimp, or frozen fish are free of metal contaminants and within weight tolerances.

● Dairy: Screens cheese, yogurt, or butter for metal and ensures consistent packaging weight.

● Bakery & Snacks: Inspects cookies, chips, or bars for contaminants and weight accuracy.

● Prepared Meals: Verifies weight and safety of ready-to-eat trays or vacuum-packed entrees.

Pharmaceuticals

● Ensures canned or packaged pharmaceuticals meet strict weight and safety standards, detecting metal particles in sealed containers.

Sanitary Products

● Verifies weight and checks for metal in hygiene products like sanitary pads, ensuring consumer safety.

The SCM-4530L2’s ability to handle high-moisture, conductive, or multi-SKU products makes it a go-to solution for automated packaging lines, including form-fill-seal and tray-pack conveyors.

Why Choose SameGram's SCM-4530L2 Combination System?

At SameGram, we are committed to delivering innovative inspection solutions tailored to your production needs. With years of expertise in manufacturing high-quality metal detectors and automatic checkweighers, we design systems that prioritize safety, efficiency, and reliability. Here's why the SCM-4530L2 Checkweigher with Metal Detector Combination System is the best choice:

● High Sensitivity: Detects ferrous (0.6-1.2mm), non-ferrous (0.8-1.5mm), and stainless steel (1.2-2.0mm) contaminants with precision, even in challenging products.

● Accurate Weighing: Offers ±0.3-1g accuracy for products up to 2000g, ensuring compliance and minimizing waste.

● Compact and Hygienic: IP65-rated, stainless steel construction suits rigorous washdown environments.

● User-Friendly: Multilingual touchscreen and 100-product memory simplify operation and changeovers.

● Comprehensive Support: From installation to compliance audits, SameGram provides end-to-end support, including calibration and maintenance services.

Technical Specifications of the SCM-4530L2

| Feature | Specification | |

Product name | ||

| Weighting Range | 1-2000g | |

Weighting Accuracy | ±0.3-1g | |

| Belt Speed | 5-28m/min | |

| Metal Detection Sensitivity | Fe: 0.6-1.2mm, Non-Fe: 0.8-1.5mm, Sus: 1.2-2.0mm | |

Inspection Section Size | L 450mm x W 230mm | |

Weighing Section Size | L ≤200mm, W ≤120mm, H ≤100mm | |

Rejection Mode | Push rod or sliding type (optional) | |

| Material | 304 Stainless Steel | |

Power Supply | AC220V ±10% | |

IP Rating | IP65 | |

Data Transmission | USB data export | |

Frequently Asked Questions (FAQs)

1. What types of metals can the SCM-4530L2 detect?

The SCM-4530L2 detects ferrous metals (e.g., iron, steel), non-ferrous metals (e.g., aluminum, copper), and stainless steel (304 and 316), ensuring comprehensive food safety.

2. How does the system handle conductive products?

The SCM-4530L2 uses multi-frequency scanning to minimize “product effect” from high-moisture or salty products, maintaining high sensitivity without false rejects.

3. Can the system integrate with my existing production line?

Yes, the SCM-4530L2's compact design and customizable configurations ensure seamless integration. Contact SameGram for a free consultation.

4. How does the system reduce product giveaway?

The checkweigher accuracy ensures products meet precise weight tolerances (±0.3-1g), rejecting underfilled or overfilled items to minimize waste and ensure compliance.

5. What support does SameGram’s combination metal detector and checkweigher systems offer?

We provide installation, calibration, training, and ongoing maintenance to maximize uptime and compliance. Visit our About Us page to learn more.

Why Trust SameGram?

As a leading manufacturer of inspection equipment, SameGram combines technical expertise with a customer-centric approach. Our SCM-4530L2 Checkweigher with Metal Detector Combination System is designed to meet the real-world challenges of food and pharmaceutical manufacturers, from ensuring safety to optimizing efficiency. We offer:

● Free Sensitivity Testing: Confirm performance with your specific products.

● Custom Configurations: Tailored solutions for your production line.

● Global Support: Dedicated service for installation, maintenance, and compliance.

Ready to Enhance Your Production Line?

Discover how the SameGram SCM-4530L2 Checkweigher with Metal Detector Combination System can streamline your quality control process. Contact us today for a free consultation or to request a product demo. Ensure safety, compliance, and efficiency with SameGram’s trusted solutions.

Related Hot-sale Metal Detector and Checkweigher

DD-500 Series is an advanced conveyor belt metal detector using smart touch-screen control. Ideal for food production and other

SCI is an automatic Checkweigher integrates industrial inkjet printer for real-time checkweighing and inkjet printing.

SCL-10060L50 is an automatic weigh price labeler with scanning, weighing scale label printing, and template customization.

SCL-8050L30 is an advanced automatic price weigh label machine with dynamic weighing, label editing, and MES/ERP integration.

SCM-4530L2 is a checkweigher metal detector combination system ,ideal for food processing and pharmaceutical on compact lines.