Food Industry Metal Detectors: Types & Selection Guide

In the food industry, ensuring product safety is paramount. Metal detectors play a crucial role in identifying and removing unwanted metal contaminants that could compromise quality or pose health risks. As a leading provider of industrial automation solutions, SameGram specializes in high-precision metal detectors designed specifically for food processing lines. With over 20 years of experience in developing reliable weighing and detection systems, we've helped thousands of businesses worldwide maintain compliance and protect their brands. In this guide, we'll explore the main types of metal detectors used in the food sector, how they work, and practical tips to help you choose the right one for your operations.

Whether you're dealing with bulk powders, packaged snacks, or liquid products, understanding these systems can solve real-world challenges like preventing recalls, reducing downtime, and meeting regulatory standards such as HACCP and ISO22000. At SameGram, our metal detectors are engineered for seamless integration, offering features like touchscreen interfaces and modular designs that make them easy to install and maintain.

Why Metal Detectors Are Essential in Food Processing

Metal contaminants can enter food products at any stage—from raw materials to packaging—often from equipment wear, broken parts, or supplier issues. A reliable metal detector acts as a safeguard, scanning for ferrous (like iron), non-ferrous (such as aluminum or copper), and stainless steel particles. This not only protects consumers but also minimizes waste and production interruptions.

For instance, imagine running a bakery line where a tiny metal shard from a mixer could contaminate dozens of loaves. A well-placed metal detector catches it early, saving you from costly rework or worse, a product recall. Based on our extensive case studies at SameGram, implementing these systems has reduced false alarms by up to 85% and boosted detection accuracy to nearly 100% in high-speed environments.

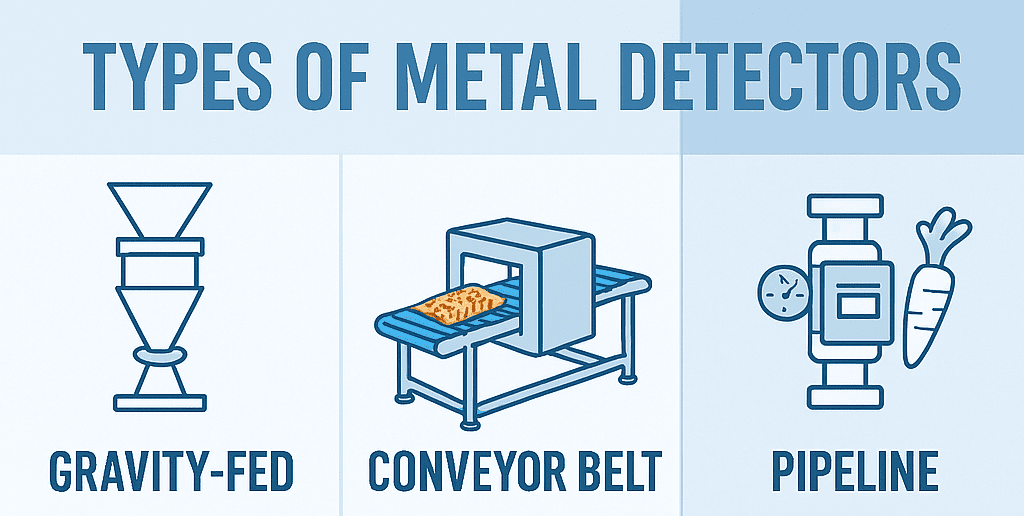

Main Types of Metal Detectors for Food Applications

There are several key types of metal detectors tailored to different food processing needs. We'll focus on the most common ones, drawing from practical applications and highlighting how SameGram's solutions address specific challenges.

These detectors are ideal for bulk, free-flowing products like powders, granules, cereals, or spices. Products drop through the detector under gravity, passing through an electromagnetic field that identifies contaminants.

How They Work: As the material falls, the system generates a magnetic field. Any metal disrupts this field, triggering an alert or automatic rejection mechanism, like a diverter flap, to remove contaminated batches without halting the flow.

Applications and Problem-Solving: Perfect for early-stage inspection in silos or hoppers, these help catch contaminants from raw ingredients before they mix into larger batches. For example, in flour or sugar processing, they prevent metal from grinding equipment from spreading. At SameGram, our free-fall metal detectors feature multi-frequency technology to handle varying product densities, reducing false positives caused by moisture or salt content—a common issue in pet food or seasoning lines.

Pros: Simple integration, cost-effective for bulk handling, and minimal maintenance.

Cons: Not suited for packaged or high-speed lines.

If you're struggling with inconsistent detection in dry goods, consider our models that auto-adjust frequencies, ensuring reliable performance even in dusty environments.

The most versatile type, these are mounted over conveyor lines to scan both bulk and packaged foods as they move along the belt. They're a staple in modern food factories for their adaptability.

How They Work: Products pass through a detection aperture where coils create an electromagnetic field. Metal causes a signal change, processed digitally to distinguish real contaminants from product effects (like salty snacks mimicking metal). Rejection systems, such as push rods or air blasts, then eject faulty items.

Applications and Problem-Solving: Used for snacks, frozen foods, bakery items, meat, and ready meals. They excel in high-throughput settings, like a potato chip line where bags need quick scans for weight and safety. SameGram's conveyor metal detectors, like our DD-720 Advanced Conveyor Belt Metal Detector and DD-360 End of Line Conveyor Metal Detector series, offer high sensitivity for detecting small particles while supporting speeds up to 25m/min. In one East China bakery case, our dual-frequency system cut false rejects dramatically, increasing output by 18% and ensuring export compliance.

Pros: Handles diverse products, easy to integrate with existing lines, and supports automation.

Cons: Requires calibration for different product types to avoid interference.

For businesses facing space constraints, our compact designs combine seamlessly with checkweighers, solving multiple quality checks in one pass.

3. Pipeline Metal Detectors (Flow-Through Systems)

Designed for liquids, pastes, or slurries, these detectors are installed in pipes to inspect flowing products without disrupting the process.

How They Work: As the product pumps through, electromagnetic sensors detect metal, often halting flow or diverting contaminated material. Advanced models use digital processing to filter out bubbles or viscosity variations.

Applications and Problem-Solving: Essential for sauces, beverages, dairy, or soups. They address challenges like detecting metal in conductive liquids (e.g., high-salt broths) where traditional detectors falter. SameGram's pipeline options incorporate IP65-rated protection for wet areas, ensuring durability in washdown environments. This helps prevent contamination in pharmaceutical or juice lines, where even tiny particles could lead to batch losses.

Pros: Non-intrusive, hygienic, and effective for continuous flow.

Cons: Limited to pumpable products; installation may require line modifications.

If metal from pumps or valves is a recurring issue, our systems' high-frequency modes provide precise detection, backed by our rigorous factory testing.

Advanced Features: Multi-Frequency and Combination Systems

While not a separate type, multi-frequency technology enhances all detectors by scanning at multiple wavelengths, improving accuracy for tricky products like wet meats or foil-packed items. SameGram leads here with auto-learning functions that adapt to your products, minimizing setup time.

For ultimate efficiency, consider combination systems like our SCM-4530L2 Checkweigher with Metal Detector. This integrates weight verification (accuracy ±0.3-1g) and metal detection in one unit, with separate rejects for each issue. It's perfect for sanitary pads, chips, or canned goods, saving space and ensuring full traceability via USB data export. In food lines, it resolves dual concerns—underweight packages and hidden metals—streamlining operations and boosting compliance.

Choosing the Right Metal Detector for Your Needs

Selecting a metal detector involves assessing your product type, line speed, and environment. Start with a risk analysis: Where are contaminants most likely? For high-moisture foods, opt for multi-frequency models to combat "product effect." Budget for maintenance—regular calibration with test samples is key to reliability.

At SameGram, we offer free sample testing to confirm sensitivity and fit. Our 4000+ m² factory in China uses bending machine and laser cutting for precision, with multi-stage quality controls like IQC, PQC, and FQC. Certified under ISO9001 and CE, we provide 12-month warranties and lifetime support, serving over 120 countries.

Factors to consider:

● Sensitivity and Speed: Ensure it detects small contaminants without slowing production.

● Integration: Modular designs like ours fit easily into existing setups.

● Hygiene: Stainless steel construction for easy cleaning.

● Data Tracking: Real-time MES/ERP connectivity for audits.

By addressing these, you'll reduce recalls and enhance efficiency—real solutions from our 5,000+ success stories.

Installation and Maintenance Best Practices

Install detectors at critical points: early for raw materials, mid-line for processing, and end-of-line for final checks. SameGram's engineers provide on-site commissioning and training to ensure a smooth setup.

Maintenance tips:

● Calibrate daily with test pieces.

● Clean regularly to prevent buildup.

● Monitor for environmental interference like vibrations.

Our cloud-based remote diagnosis offers 72-hour global response, minimizing downtime.

About SameGram: Your Trusted Partner in Food Safety

SameGram is a high-tech enterprise focused on intelligent checkweighing and detection solutions. From our state-of-the-art factory with GMP standards, we deliver customized metal detectors that meet the highest hygiene and accuracy needs. Trusted by industry leaders, we promote efficient, safe systems—contact us for a consultation and elevate your production line.

For more details, visit our products page or request a demo. Protect your products with SameGram's proven technology today.