Custom Inline Checkweigher Integration for Conveyors

Introduction to Checkweigher Systems and Conveyor Integration

In today's fast-paced manufacturing environments, ensuring product weight compliance is crucial for maintaining quality, reducing waste, and meeting regulatory standards. A dynamic checkweigher is an essential automated system used in factories to verify if products meet designed weight specifications during production. This is particularly vital in industries like food and pharmaceuticals, where underweight or overweight items can lead to recalls, fines, or safety issues. At SameGram, we specialize in high-precision checkweighers that integrate seamlessly with conveyor systems, providing custom solutions tailored to your production line needs.

As a high-tech enterprise with over 5,000 success stories, SameGram combines innovative R&D with modular designs to deliver intelligent weighing solutions. Our expertise in dynamic checkweighers ensures high-speed accuracy, helping businesses like yours optimize efficiency and compliance. Explore our full range of checkweighers on our product page or learn more about our commitment to quality on our about us page.

Key Features of Custom Checkweigher Conveyor Design Integration

Custom integration of checkweighers with conveyors addresses common challenges such as inconsistent weights, production bottlenecks, and space constraints. Drawing from industry-leading designs, SameGram's solutions incorporate advanced features for superior performance:

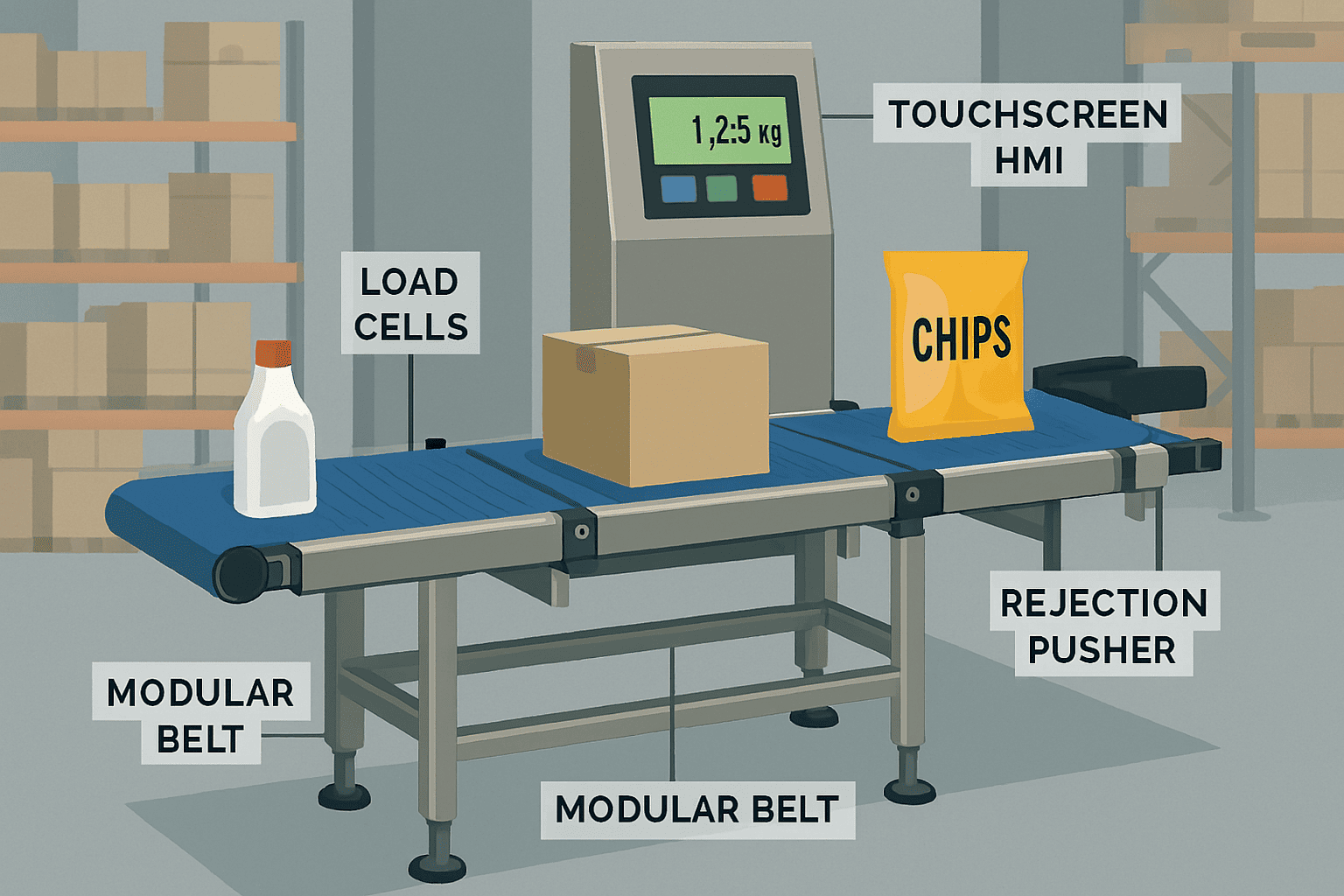

● High-Precision Weighing: Our checkweighers use sensitive load cells and high-speed algorithms for accuracies as fine as ±0.05g, even at speeds up to 180 pieces per minute. This ensures reliable in-motion weighing without halting your conveyor flow.

● Modular Conveyor Designs: Available in stainless steel for hygienic environments (IP65-rated for dustproof and wash-down), with adjustable belt speeds (5-120m/min) and customizable sizes to fit rigid or flexible packages.

● Rejection Systems: Integrated options like pushers, drop beds, air blasts, or multi-lane sorters automatically remove non-compliant items, minimizing waste and downtime.

● Data Integration and Monitoring: Real-time data logging via USB/Ethernet, with touchscreen HMIs for easy setup. Supports AI-assisted inspection and Industry 4.0 connectivity for seamless feedback to upstream equipment like fillers or labelers.

● Hygienic and Durable Build: Food-grade materials, flushable structures, and anti-corrosion finishes meet GMP/ISO standards, ideal for food, pharma, and chemicals.

These features solve practical problems like vibration interference (via advanced compensation tech) and varying product sizes, ensuring your production line runs smoothly.

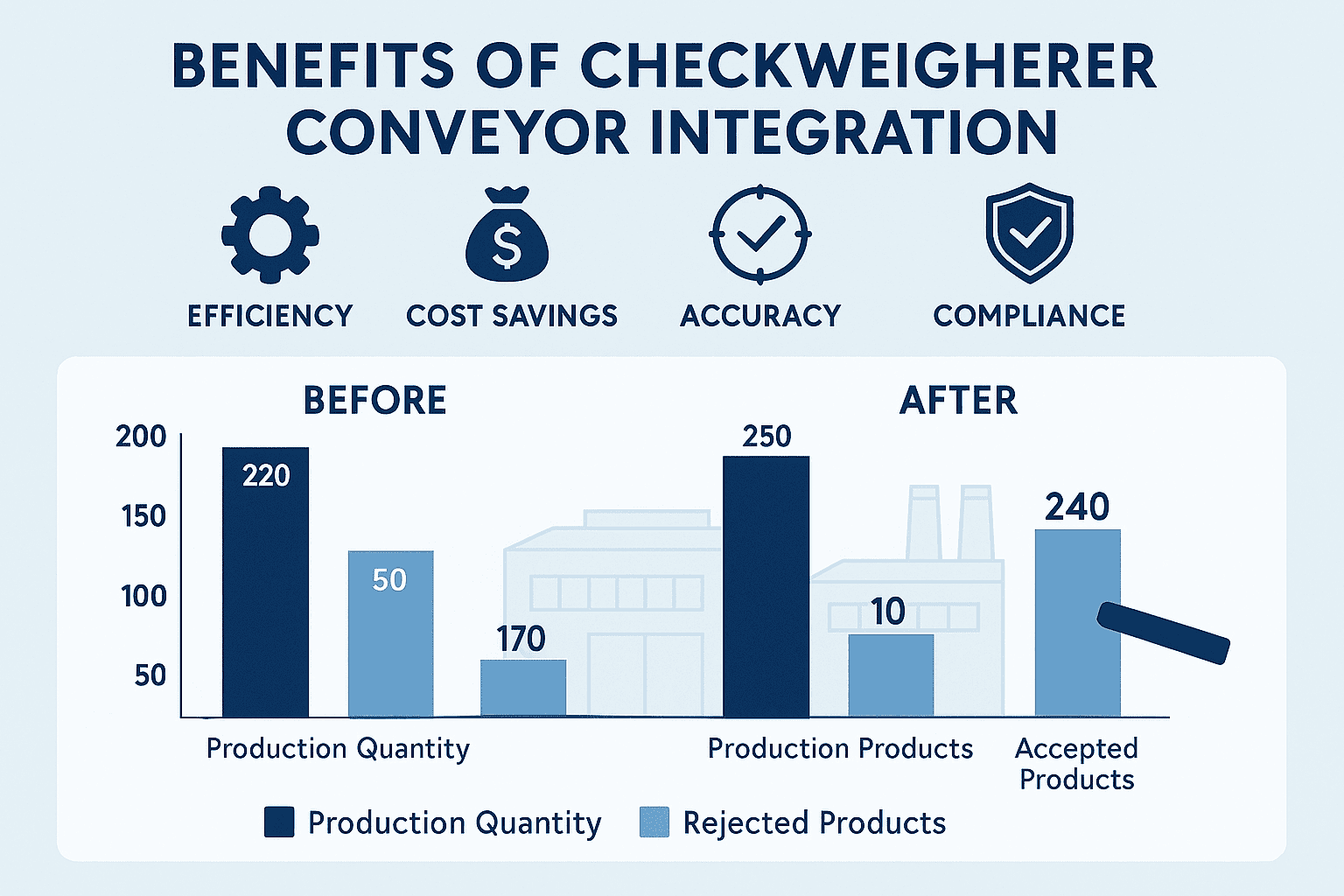

Benefits of Integrating Checkweighers with Conveyors

Integrating a checkweigher with your conveyor system offers tangible advantages, backed by SameGram's proven track record in reducing labor costs and enhancing product quality:

● Improved Efficiency and Throughput: Achieve rates up to 350 items per minute, cutting manual checks and boosting overall equipment effectiveness (OEE). For instance, our systems have helped clients save up to 40% in labor costs by automating weight verification.

● Cost Savings and Waste Reduction: Real-time detection prevents overfilling or underfilling, minimizing material giveaway and recalls. Compliance with regulations like MID and local packaging laws avoids fines.

● Enhanced Quality Control: Color-coded indicators and automated sorting ensure only qualified products proceed, protecting your brand reputation in industries such as food processing and logistics.

● Scalability and Flexibility: From entry-level static models to multi-lane dynamic setups, our custom solutions grow with your business, supporting weights from 0.1g to 80kg.

● Long-Term Reliability: With a 12-month warranty, lifetime technical support, and sustainable designs that reduce energy consumption, SameGram checkweighers deliver ROI through durability and minimal maintenance.

By addressing issues like inaccurate weights in high-speed lines, our integrations help users maintain consistent output and meet ESG goals.

Step-by-Step Process for Custom Integration

Implementing a custom checkweigher belt conveyor solution at SameGram follows a structured, user-focused process to ensure seamless adoption and problem-solving:

1. Initial Consultation and Assessment: We evaluate your production line's speed, product types, space, and compliance needs. Free sample testing and on-site demonstrations help identify pain points like inconsistent spacing or environmental factors.

2. Design and Customization: Using modular architecture, we tailor the system—selecting conveyor lengths (e.g., 26” to 36”), rejection mechanisms, and integration with metal detectors or x-ray systems. Explosion-proof or heavy-duty options are available for specialized environments.

3. Prototyping and Testing: Build a prototype with high-precision load cells and calibrate statically/dynamic for your specific weights. Test for accuracy (±0.5g at 2 Sigma) and speed compatibility.

4. Installation and Integration: On-site setup with minimal disruption, including conveyor angle adjustments (up to 12°) and data interfaces (RS-232/Ethernet) for PLC connectivity.

5. Training and Optimization: Provide virtual training, remote diagnostics, and real-time data tools to monitor metrics like qualified counts and rejects. Ongoing support ensures long-term efficiency.

6. Maintenance and Upgrades: Regular calibration tips (e.g., using test weights >½ heaviest package) and priority service plans keep your system reliable.

This process resolves real-world issues, such as integrating into existing lines without layout changes, as seen in our Belarus food factory case where labeling accuracy reached 99.8%.

Customization Options Tailored to Your Needs

At SameGram, customization is at the heart of our expertise, allowing us to adapt checkweighers for diverse applications:

● Conveyor Configurations: Belt, chain, or skid types with adjustable heights and widths for small packages (e.g., cans) or bulky items (e.g., 80kg sacks).

● Advanced Add-Ons: Multi-zone weight comparison, dual-lane setups, or combi-check with contaminant detection for comprehensive quality assurance.

● Software Enhancements: Up to 100 product profiles, data export to Excel/CSV, and AI for predictive maintenance.

● Industry-Specific Adaptations: Hygienic designs for food/pharma, robust frames for logistics, or high-speed models for agriculture.

Our customer-driven approach starts with listening—contact us for free design consultations via our homepage.

Case Studies: Real-World Success with SameGram Checkweighers

To demonstrate our authority, here are examples inspired by industry implementations and SameGram's successes:

● Food Processing Factory: A client integrated our SC2-8050L30 model into a high-speed conveyor, achieving ±3g accuracy at 90m/min. This reduced waste by 25% and ensured compliance, mirroring our Belarus case with 40% labor savings.

● Pharmaceutical Line: Custom multi-lane setup with rejection sorters handled 250 items/min, integrating with x-ray for dual weight/contaminant checks, solving hygiene and precision issues.

● Logistics Warehouse: Heavy-duty checkweigher for 30kg parcels on angled conveyors, with data logging for inventory optimization, extending equipment life beyond 10 years as seen in durable designs.

These cases highlight how SameGram's solutions provide trustworthy, expert-driven results.

SCL-7035L5 is a weigh price labeler that integrates a weighing machine with label printer(s),which is very widely used

Categories: Checkweigher Combination System

Brand: SameGram

Model: SCL-7035L5

Weighting range: 1-5000g

Belt speed: 15-50pcs/min

Weighting accuracy: ±0.5-2g

Weighting section size: L 700mm*W 300mm

Applicable product size: L≤500mm; W≤300mm

Labeling accuracy: ±5+30mm

Why Choose SameGram for Your Checkweigher Machines Needs?

As an innovation-driven leader in industrial weighing, SameGram offers custom solutions that promote intelligent upgrading and sustainability. With certifications like ISO and a focus on R&D, we ensure our in-motion checkweighers are precise, efficient, and reliable. Trusted by leaders in food, pharma, and more, we provide fast delivery, free testing, and comprehensive support.

Ready to integrate a custom checkweigher into your conveyor system? Visit our homepage or contact us today for a tailored quote.

Related Hot-Sale Checkweigher System

SCP6 is a dynamic checkweighing system for small packages. it supports multi-lane control, fast data export and GMP compliance.

The SC3-10060L50 is an dynamic end of line checkweigher machine with built-in rejector, especially designed for large items.

The SC1-C-3523L1 is the most suitable checkweigher for small packages. It has positive and negative weight selection functions and is compact and economical.

SWSD-4523L2 is a weight sorter with food-grade material and IP65 protection double-layer design ensures stronger waterproofnessvery suitable for fish and shrimp weight sorting.

SCL-10060L50 is an automatic weigh price labeler with scanning, weighing scale label printing, and template customization.