Checkweigher Systems Guide: Real-Time Printing & Labeling Integration

In today's fast-paced manufacturing world, ensuring product quality and compliance is more critical than ever. If you're in the food industry or any sector where precise weight control matters, you've likely heard about checkweigher systems. These tools are game-changers for maintaining standards on production lines. But when you integrate them with real-time printing and automatic labeling machine, you elevate your operations to a whole new level of efficiency and accuracy.

This guide dives deep into everything you need to know about checkweigher systems combined with integrated real-time printing and automatic labeler machine. We'll cover how they work, their benefits, and practical applications to help solve real-world challenges like inconsistent product weights or labeling errors. As a leading provider in this space, SameGram brings years of expertise to the table, offering reliable solutions tailored to industries like food processing. Whether you're upgrading your line or starting fresh, this resource will equip you with the knowledge to make informed decisions.

What is a Checkweigher System?

At its core, a dynamic checkweigher is a specialized machine used in factories to verify that products meet specific weight requirements during production. Imagine a conveyor belt where items zip by— the checkweigher machine weighs each one dynamically without stopping the flow. If a product is too light or too heavy, it's automatically rejected, ensuring only compliant items proceed.

This is especially vital in food manufacturing, where regulations demand that products like packaged snacks or ready meals adhere to labeled weights. Underfilling can lead to customer complaints and fines, while overfilling wastes resources. In-line checkweighers address these issues head-on by providing real-time feedback, helping maintain consistency and safety.

Drawing from our experience at SameGram, a high-tech enterprise with over 20 years in industrial automation, our inline checkweighers are built to exceed industry standards. They're designed for high-speed lines, offering precision that minimizes errors and boosts throughput. For instance, our systems can handle a wide range of product weights, from lightweight cosmetics to heavier food packages, all while integrating seamlessly into existing setups.

The Importance of Integrated Real-Time Printing and Labeling

Now, let's talk about the magic of integration. Real-time printing and weighing labeling takes the checkweigher combination system's data— like the exact weight— and feeds it directly to a connected printer and applicator. This happens on the same conveyor belt: weigh, print a custom label (with details like weight, price, or barcode), and apply it instantly. No manual intervention, no delays.

Why does this matter? In food production, accurate labeling isn't just nice— it's essential for traceability and compliance with standards like FDA or EU regulations. Imagine catching a weight discrepancy and immediately updating the label to reflect it, preventing mislabeled products from reaching shelves. This integration reduces human error, speeds up the line, and enhances overall quality control.

From a practical standpoint, businesses often face challenges like mismatched data or slow manual labeling, which can bottleneck production. Integrated systems solve these by automating the process, saving time and reducing waste. At SameGram, we specialize in these combined solutions, ensuring our clients achieve efficient, safe operations that align with sustainable practices.

How These Systems Work

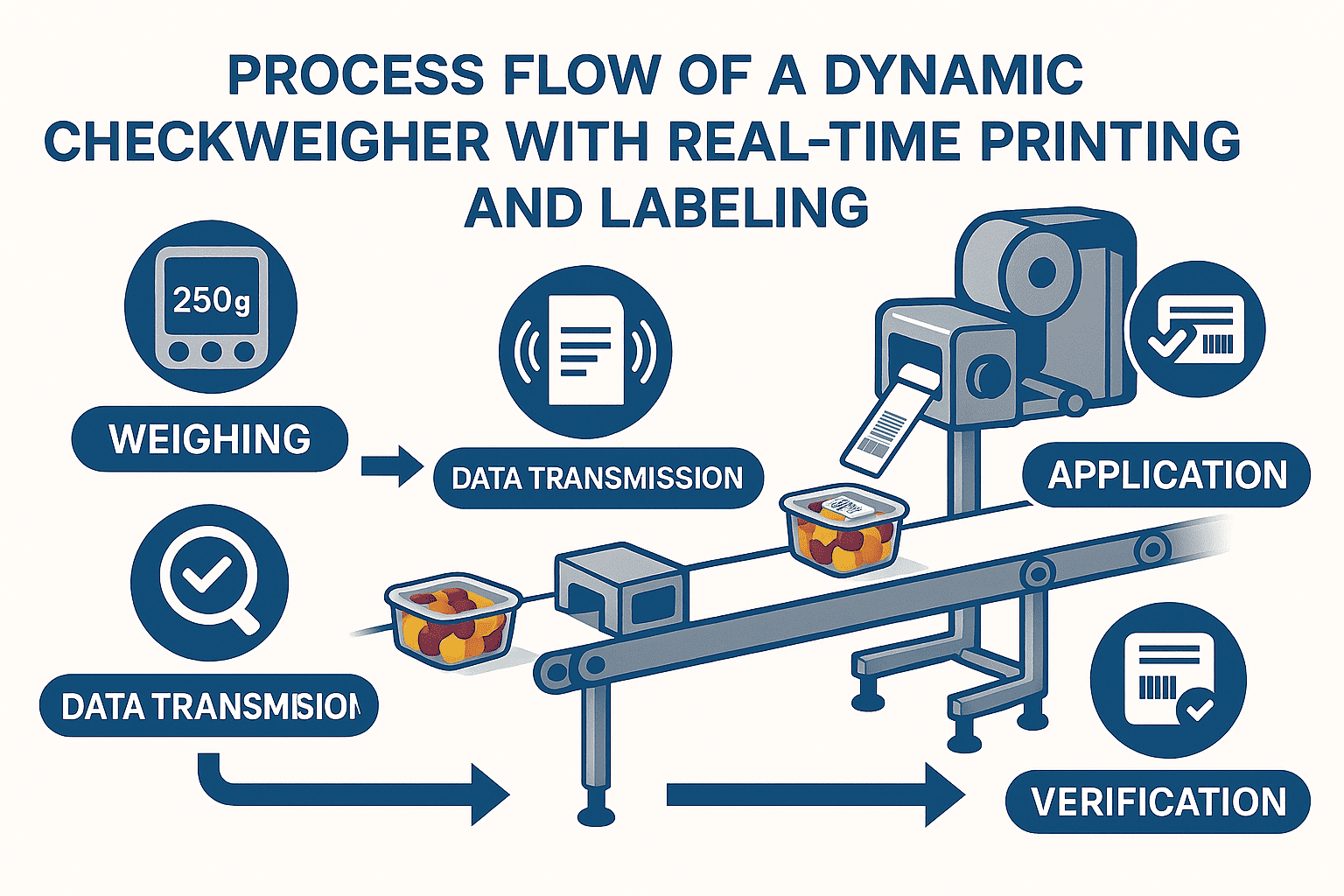

Understanding the mechanics can demystify these systems and show how they tackle everyday production hurdles. Here's a step-by-step breakdown:

1. Product Entry and Weighing: Products enter the industrial checkweigher via a conveyor. Using advanced sensors, the system measures weight dynamically at high speeds. If it's off-spec, a reject mechanism (like a pusher arm) removes it.

2. Data Transmission: The weight data is sent instantly to a connected computer or control unit. This real-time transfer is key— no lags mean no production slowdowns.

3. Printing the Label: Based on the weight and other predefined info (e.g., batch number or expiration date), a thermal printer generates a custom label. This could include barcodes, QR codes, or variable data like price.

4. Label Application: An applicator, often using air-jet technology for precision, affixes the label to the product without halting the line. Everything happens in one fluid motion on the same belt.

5. Verification and Exit: Many systems include optical inspection to confirm the label is correct and properly placed. Compliant products continue; others are diverted.

This seamless workflow addresses common pain points like overfilling (which inflates costs) or labeling inaccuracies (which risk recalls). For example, in a busy food line processing poultry packs, this setup ensures every item is weighed accurately and labeled with the right weight info, promoting trust and efficiency.

SameGram's combination systems exemplify this process. Our models, like those in our SCL series Checkweigher Combination System, feature modular designs that sync weighing with printing and labeling, supporting speeds up to 50 pieces per minute. They're built with hygienic stainless steel, making them ideal for washdown environments in food plants.

Key Features and Benefits

When evaluating these systems, focus on features that deliver real value. Look for modular setups that allow customization— think adjustable conveyors for different product sizes or integration with ERP systems for data tracking.

Key features include:

● High Precision: Accurate to within grams, reducing false rejects.

● Speed and Throughput: Handles high volumes without compromising quality.

● Hygienic Design: Easy-to-clean materials compliant with food safety standards.

● Real-Time Data Sync: Prevents mismatches between weight and labels.

● User-Friendly Interfaces: Touchscreens for quick setup and monitoring.

The benefits are tangible: lower operational costs through waste reduction, improved compliance to avoid penalties, and enhanced traceability for faster issue resolution. In one scenario, a food processor struggling with manual labeling saw a 40% efficiency boost after switching to an integrated system, cutting down on rework and downtime.

At SameGram, our checkweigher combinations stand out with features like IP65 protection for wet areas and customizable templates for label printing. Backed by rigorous quality controls— from incoming inspections to final testing— our systems ensure long-term reliability, with a 12-month warranty and lifetime support.

Applications in Various Industries

These systems shine in food production but extend far beyond. In pharmaceuticals, they verify pill counts and label vials accurately. Logistics benefits from weight checks on packages to optimize shipping. Cosmetics lines use them for ensuring bottle fills meet specs.

For food specifically, consider fresh produce or dairy: weighing ensures portions are right, while real-time labeling adds sell-by dates or nutritional info on the fly. This integration helps meet HACCP or IFS standards, solving issues like contamination risks or inconsistent packaging.

SameGram has delivered over 5,000 units worldwide, serving 120+ countries in food, pharma, and more. Our factory, spanning 4,000 square meters with bending machine and laser cutting, produces these systems to global certifications like CE and ISO9001, guaranteeing they perform in diverse settings.

Choosing the Right System for Your Needs

Selecting a system starts with assessing your production: What speeds do you need? What product varieties? Budget for modularity to future-proof your investment.

Consider factors like:

● Integration ease with existing lines.

● Maintenance requirements— opt for durable, low-downtime designs.

● Scalability for growing operations.

● Supplier support, including testing and customization.

To avoid pitfalls, test samples first. SameGram offers free product testing, providing videos and reports to confirm fit. Our experts guide you through customization, ensuring the system resolves your specific challenges, like space constraints or high-speed demands.

SCL-7035L5 is a weigh price labeler that integrates a weighing machine with label printer(s), which is widely used

Categories: Checkweigher Combination System

Brand: SameGram

Model: SCL-7035L5

Weighting range: 1-5000g

Belt speed: 15-50pcs/min

Weighting accuracy: ±0.5-2g

Weighting section size: L 700mm*W 300mm

Applicable product size: L≤500mm; W≤300mm

Labeling accuracy: ±5+30mm

Introducing SameGram's Innovative Solutions

As a trusted name in intelligent weighing and labeling, SameGram stands ready to partner with you. Our combination systems, such as the SCL-10060L50 Advanced Weigh Price Labeler, integrate checkweighing with label printing for weights from 10g to 50kg, achieving accuracies of ±0.5-2g. These are perfect for end-of-line automation, connecting to MES/ERP for seamless data flow.

What sets us apart? Our commitment to innovation— driven by a dedicated R&D team— and sustainability, with designs that cut waste and energy use. With proven OEM/ODM experience and fast delivery from stock, we help clients like food processors achieve 68% fewer false rejects. Visit our site at sameGram.com to explore more.

Real-World Examples

Take a food manufacturer dealing with variable fruit pack weights. By implementing an integrated checkweigher combination system, they automated labeling with accurate weights, reducing overfills by 20% and speeding up the line. Another case: a pharma firm used our system for blister packs, ensuring compliance and cutting manual checks.

These stories highlight how these systems turn challenges into efficiencies, backed by SameGram's global service network for quick support.

Conclusion

Checkweigher systems with integrated real-time printing and labeling are essential for modern manufacturing, offering precision, efficiency, and compliance. By addressing weight inconsistencies and labeling errors, they help businesses thrive.

If you're ready to optimize your line, SameGram is here with tailored, reliable solutions. Contact us today for a consultation— let's build a more efficient future together.

Hot-Sale Weigh Price Labeler

SCL-7035L5 is a weigh price labeler that integrates a weighing machine with label printer(s),which is very widely used

SCI is an automatic Checkweigher integrates industrial inkjet printer for real-time checkweighing and inkjet printing.

SCL-10060L50 is an automatic weigh price labeler with scanning, weighing scale label printing, and template customization.

SCL-8050L30 is an advanced automatic price weigh label machine with dynamic weighing, label editing, and MES/ERP integration.