Checkweigher Combination Systems: OEM/ODM Customization Guide

Welcome to the ultimate guide on checkweigher combination systems and OEM/ODM customization services. As a leading provider of intelligent checkweighing and industrial weighing solutions, SameGram brings over 16 years of expertise to help businesses in industries like food, pharmaceuticals, cosmetics, logistics, and more. Our high-tech enterprise integrates R&D, production, and sales to deliver accurate, efficient, and reliable automation solutions. With more than 5,000 success stories and a commitment to Industry 4.0-ready systems, we ensure your production lines meet stringent weight regulations and safety standards. This guide draws from industry best practices to address key considerations when procuring and customizing checkweigher combination systems, helping you solve real-world challenges like integration, accuracy, and compliance.

A checkweigher combination system is an integrated solution that combines a checkweigher—designed to verify if products meet specified weight requirements—with complementary equipment for enhanced quality control. Checkweighers ensure products like food items comply with design specifications and regulations, preventing underweight or overweight issues that could lead to waste, recalls, or non-compliance fines. When combined with other devices, these systems provide comprehensive inspection.

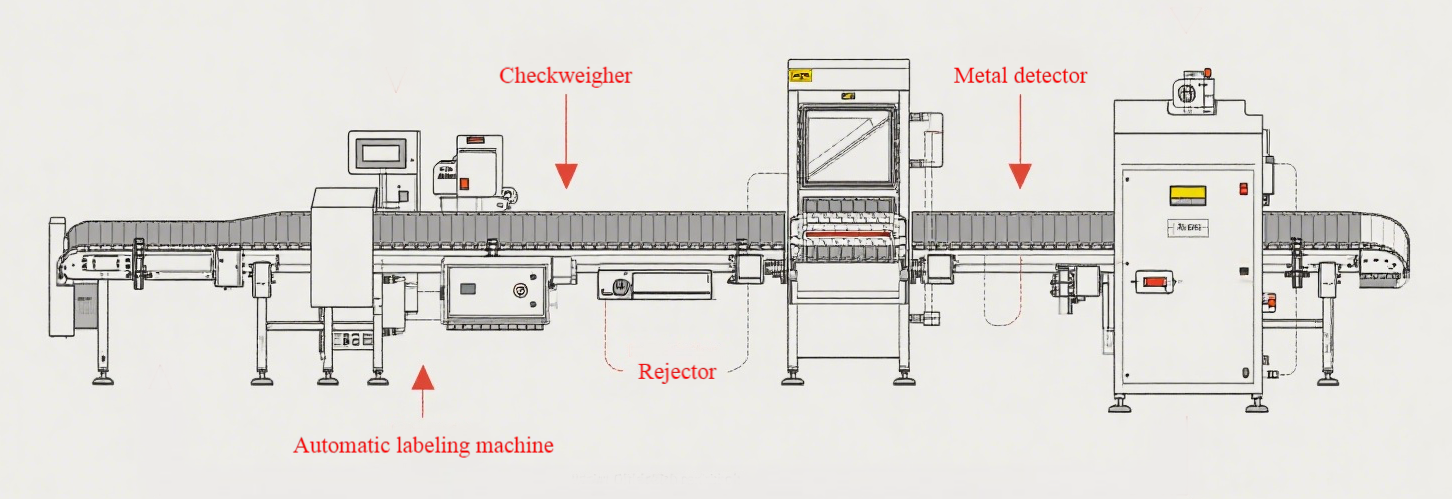

Key integrated components include:

● Conveyor Belts: Facilitate smooth product flow at high speeds (up to 120m/min in SameGram models), ensuring seamless movement through the weighing process.

● Rejector Mechanisms: Automatically remove non-compliant products using pneumatic pushers, air jets, or diverters, minimizing downtime and maintaining line efficiency.

● Print and Label Machines: Enable real-time labeling for traceability, such as printing batch codes or weights, with adjustable positions for precision.

● Metal Detectors: Detect metallic contaminants that violate product safety standards, often integrated for food and pharmaceutical applications to meet FDA, USDA, and GMP requirements.

At SameGram, our High-Precision and Ultra-Fast Checkweigher series exemplifies this, offering modular designs that integrate metal detection, labeling, and more, with accuracies as fine as ±0.05g and speeds up to 180 pieces per minute. This setup not only verifies weight but also ensures contaminant-free products, addressing practical issues like hygiene in wet environments through IP65-rated stainless steel construction.

Benefits of Checkweigher Combination Systems

Implementing a checkweigher combination system boosts production efficiency, reduces costs, and enhances product quality. Here are the key advantages:

● Improved Accuracy and Compliance: High-precision weighing (e.g., ±0.1g) combined with metal detection prevents regulatory violations, as seen in industries requiring NIST net content laws. SameGram's systems, certified to MID and ISO standards, help achieve 99.8% labeling accuracy, reducing rework by up to 40%.

● Increased Throughput: Handle up to 650 pieces per minute without compromising speed, ideal for high-volume lines. Integration minimizes operation errors and space usage.

● Cost Savings: Automated rejection and data logging cut labor costs and material waste. For instance, our customizable solutions have saved clients 40% in labor through seamless ERP/MES integration.

● Enhanced Safety and Traceability: Metal detectors ensure contaminant-free products, while software like Comscale4 provides real-time data for audits, supporting GMP/ISO cleanliness.

● Sustainability: Modular upgrades extend equipment life, reducing energy use and waste—aligning with SameGram's mission for efficient, sustainable automation.

These benefits are backed by our 12-month warranty, lifetime technical support, and free sample testing, demonstrating our trustworthiness and expertise.

How to Choose the Right Checkweigher Combination System

Selecting the ideal system involves evaluating your specific needs. Based on expert guides, consider these factors:

1. Product Characteristics: Assess size, shape, weight, and type (e.g., bottles, pouches). SameGram's range covers 0.1g-80kg, with options for soft fruits or pharmaceuticals.

2. Production Speed and Accuracy: Match throughput to your line (e.g., <0.5 seconds per item). Prioritize systems with Active Vibration Compensation for precision in dynamic environments.

3. Environmental Factors: Choose hygienic, washdown designs for wet or dusty settings. Our IP65-rated models resist corrosion and maintain accuracy.

4. Integration Requirements: Ensure compatibility with conveyors, rejectors, metal detectors, and labelers. Look for interfaces like Ethernet, RS232, and Wi-Fi for data sharing.

5. Regulatory Compliance: Verify certifications (e.g., FDA, 21 CFR Part 11). SameGram systems support audit trails and user access levels.

6. Supplier Evaluation: Opt for experienced providers with training, support, and customization. With 16 years in the field, SameGram offers onsite demos and remote diagnostics.

Avoid pitfalls like ignoring integration, which can cause errors—always test with your products.

Key Considerations for Integration in Checkweigher Combination Systems

Integration is critical for solving practical problems like bottlenecks or false rejects. Here's what to consider:

● Conveyor Belts: Ensure adjustable speeds and food-grade materials. SameGram's modular conveyors adapt to product flow, reducing jams.

● Rejector Mechanisms: Select based on product fragility—air jets for light items, pushers for sturdy ones. Our systems offer multi-rejection options for sorted rework.

● Print and Label Machines: Integrate for real-time data printing. Consider label position accuracy and speed synchronization to avoid misalignments.

● Metal Detectors: Position them upstream to detect contaminants early. Combined units save space and ensure dual weight/contaminant checks.

● Other Challenges: Address vibrations with AVC tech, data connectivity for traceability, and modularity for future upgrades. SameGram's hardware interfaces (e.g., RJ45) enable seamless MES/ERP links, resolving issues like manual reporting.

For tailored advice, fill out our selection forms: Checkweigher with Metal Detector or Real-Time Labeling.

SCL-10060L50 is an automatic weigh price labeler with scanning, weighing scale label printing, and template customization.

Categories: Checkweigher Combination System

Brand: SameGram

Model: SCL-10060L50

Weighting range: 10-50g

Weighting accuracy: ±0.5-2g

Labeling speed: 15-25pcs/min

Labeling accuracy: ±5-10mm

Weighting section size: L 500mm*W 300mm

Applicable product size: L≤300mm; W≤300mm

OEM/ODM Customization Services for Checkweigher Combination Systems

Customization via OEM (manufacturing your design) or ODM (full design and manufacturing) ensures systems fit your unique needs. SameGram's process includes:

1. Consultation and Site Survey: We assess your line for 3D planning and simulations.

2. Design and Prototyping: Tailor features like weight ranges, speeds, and integrations.

3. Testing and Validation: Free sample tests verify performance.

4. Production and Delivery: Fast turnaround with quality controls.

5. Support: Lifetime assistance, including remote calibration.

Examples: A multi-lane system for a beauty cream maker boosted throughput by 28%; a compact pharma unit met space constraints. Our AI-assisted, modular designs make us a trusted OEM/ODM partner.

Case Studies: Real-World Success with SameGram

● Food Processing Factory (Belarus): Integrated checkweigher with labeling reduced labor by 40% and achieved 99.8% accuracy.

● Pharmaceutical OEM: Custom compact unit with metal detection ensured 21 CFR compliance in a limited space.

● Cosmetics Manufacturer: A multi-lane system with vision inspection increased efficiency by 28%, meeting EU GMP.

These demonstrate our authority in solving integration challenges.

Conclusion: Partner with SameGram for Your Checkweigher Needs

This guide equips you to make informed decisions on checkweigher combination systems and OEM/ODM services. At SameGram, we're committed to your success—explore our products or contact us. Elevate your production with our proven solutions today!