Checkweigher & Labeling Integration Guide 2025: Key Benefits

Introduction: Why Checkweighers and Labeller Integration Matters in Modern Manufacturing

In today's fast-paced manufacturing world, especially in industries like food, pharmaceuticals, and electronics, ensuring every product meets exact weight specifications and is properly labeled is crucial. A industrial checkweigher is a vital tool that verifies if products conform to designed weight standards, helping maintain quality and regulatory compliance. When paired with a weigh price labeller, which takes the weight data, processes it via computer, and prints and applies labels seamlessly on the same conveyor line, the result is a streamlined process: weighing, printing, and automated labeling all in one go.

At SameGram, we've been at the forefront of providing reliable industrial solutions since our founding in 2011. Based in Dongguan, Guangdong Province, China, our 5,000-square-meter factory is equipped with advanced bending machine and laser cutting machine, and a dedicated R&D team of over 20 engineers. We specialize in integrated checkweigher solutions and weigh price labeling machines that integrate flawlessly to solve real-world production challenges. Our systems, like the Checkweigher with Labeller Combination System and the Weigh Price Labeller series, are designed for precision, speed, and traceability, helping businesses worldwide boost efficiency and reduce errors.

In this article, we'll explore the top benefits of integrating these technologies, drawing from our expertise and customer success stories. Whether you're dealing with variable product weights, compliance issues, or scaling production, these insights can help you make informed decisions.

1. Enhanced Accuracy and Reduced Errors

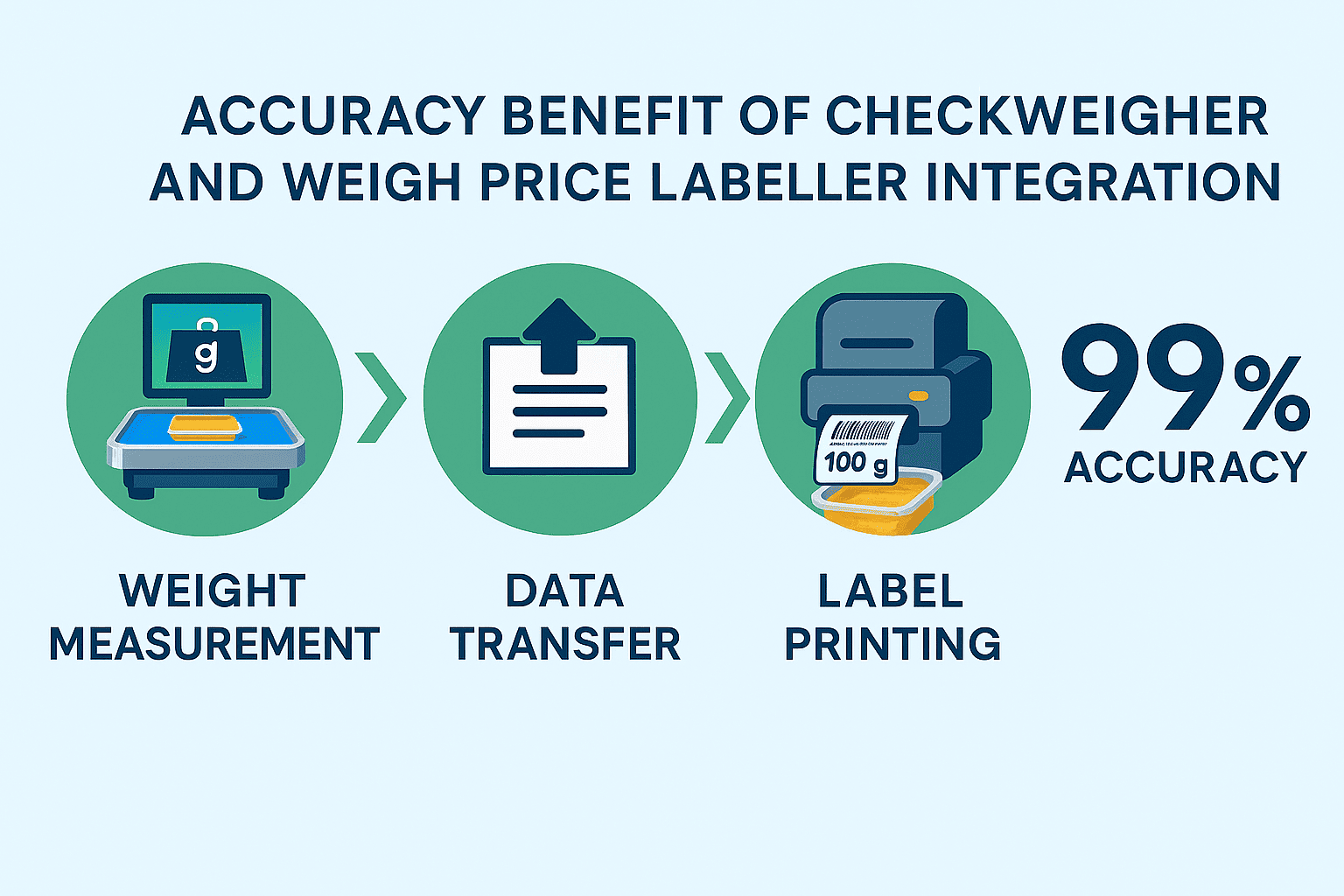

One of the biggest headaches in production lines is inconsistency in product weights and automated labeling. Manual processes often lead to human errors, like misreading scales or applying incorrect labels, which can result in costly recalls or wasted materials. Integrating an inline checkweigher with a print-and-apply labeling machine eliminates these risks by automating the entire workflow.

Here's how it works in practice: The in-motion checkweigher measures the product's weight in real-time as it moves along the conveyor. If it's within the specified range (with accuracy up to ±0.1g in our high-precision models), the data is instantly sent to the weigh price labeller. This system then prints customized labels—including weight, price, barcodes, or QR codes—and applies them precisely, ensuring every package is compliant and traceable.

For instance, in the food industry, where regulations demand exact net weights, our Integrated Checkweigher with Labeller Combination System has helped clients achieve 99.9% label accuracy. This not only meets standards like FDA or HACCP but also builds consumer trust. Imagine avoiding a recall because a batch of packages was underweight—our integrated systems catch and reject non-compliant items automatically, saving you time and money.

2. Increased Production Efficiency and Speed

Time is money in manufacturing, and bottlenecks from separate weighing and labeling steps can slow down your entire line. By integrating checkweighers with print-and-apply machines, you create a seamless, high-speed operation that keeps products moving without pauses.

SameGram's Weigh Price Labeling Machine series, such as the SL Model Weigh Price Labeller, supports automated labeling speeds of 20-40 pieces per minute with ±2-20mm accuracy on flat tops or optional sides. When combined with our integrated checkweighers, the process handles real-time printing. This modular design fits into compact spaces, making it ideal for factories with limited layouts.

Real-world example: A vegetable packaging company in Vietnam integrated our system to handle multi-SKU demands in a wet environment. The result? Significant efficiency gains, with automatic size detection and synchronized weighing-labeling, allowing them to meet export standards effortlessly. If your line struggles with slow manual labeling or frequent switches between products, this integration can cut downtime and boost throughput, directly impacting your bottom line.

3. Improved Compliance and Traceability

Regulatory compliance isn't optional—it's essential for avoiding fines and maintaining market access. Checkweighing system ensure weights align with legal requirements, while integrated labeling adds verifiable data like batch numbers, expiration dates, and origin info.

Our systems at SameGram are built with traceability in mind. The weighing machine with label printer Combination System links each label to product data, integrating seamlessly with MES/ERP systems for audits and recalls. Features like barcode and QR code verification ensure export readiness and multilingual support caters to global markets.

Consider pharmaceutical or food sectors where traceability can prevent contamination issues. By automating data capture and automated labeling, you create a digital trail that's easy to audit. Customers often tell us how our IP66-rated, stainless steel constructions have helped them pass hygiene inspections with ease, turning compliance from a chore into a competitive advantage.

SCL-8050L30 is an advanced automatic price weigh label machine with dynamic weighing, label editing, and MES/ERP integration.

Categories: Inline Checkweigher Combination System

Brand: SameGram

Model: SCL-8050L30

Weighting range: 10-30kg

Weighting accuracy: ±0.5-2g

Labeling speed: 15pcs/min

Weighting section size: L 800mm*W 300mm

Applicable product size: L≤500mm; W≤500mm

Labeling accuracy: ±5-10mm

4. Cost Savings Through Waste Reduction and Scalability

Overfilling packages to avoid underweight complaints wastes materials, while errors lead to rework. Integration minimizes these by precise weighing and immediate automated labeling, ensuring you use just the right amount.

SameGram's flexible configurations—like label-only, label+scan, or full weigh-price setups—allow you to scale without overhauling your line. Our SL-V Model Weigh Price Labeller with vision systems adds post-packaging inspection, reducing defects further. In one case, a client saw ROI within months by cutting label waste and labor costs.

For growing businesses, this means adapting to higher volumes without hiring more staff. Our modular designs support upgrades like vision checks or checkweighing, making your investment future-proof and economical.

5. Enhanced Flexibility and Customization for Diverse Needs

No two production lines are identical, so your equipment shouldn't be one-size-fits-all. Integrating checkweighers with print-and-apply machines offers versatility for various products, from bottles to boxes.

At SameGram, we customize solutions based on your product dimensions, weight ranges, and line layouts. The SL3 Multi-Axis Labeller handles bottles, jars, or wires with easy switching. Touchscreen interfaces and servo controls ensure ±2-20mm accuracy, while compact designs fit tight spaces.

This flexibility solves problems like handling irregular shapes or switching SKUs quickly. Our one-stop service—from customization to installation and training—ensures a smooth rollout, as seen in our global projects.

About SameGram: Your Partner in Precision Weighing and Labeling

Founded in 2011, SameGram is a leading provider of industrial inline checkweighers and weigh price labellers, with a strong focus on innovation and quality. Our ISO/MID-certified factory in Dongguan employs over 100 skilled workers and engineers, producing systems trusted by more than 100 customers worldwide. We offer free quotes, quick responses, and comprehensive support, including virtual commissioning and remote training.

Explore Our Products, or learn more about our Checkweigher with Labeller Combination System and Weigh Price Labeller.