Key Considerations When Purchasing Checkweigher Combination Systems

As a leading provider of intelligent checkweighing and industrial weighing solutions, SameGram is a high-tech enterprise integrating research, development, production, and sales. With a focus on accurate, efficient, and reliable industrial automation weighing solutions, we independently develop and produce automatic weighing systems and dynamic checkweigher equipment for high-standard industries such as food, pharmaceuticals, logistics, and cosmetics. Our checkweigher combination systems, such as the Checkweigher Combination System SCM-4530L2, integrate seamlessly with metal detectors, conveyors, rejectors, and labelers to ensure product weight compliance and contaminant-free output. In this comprehensive guide, we'll explore the essential factors to consider when procuring these integrated solutions, drawing from industry best practices to help you make an informed decision that boosts efficiency, safety, and compliance.

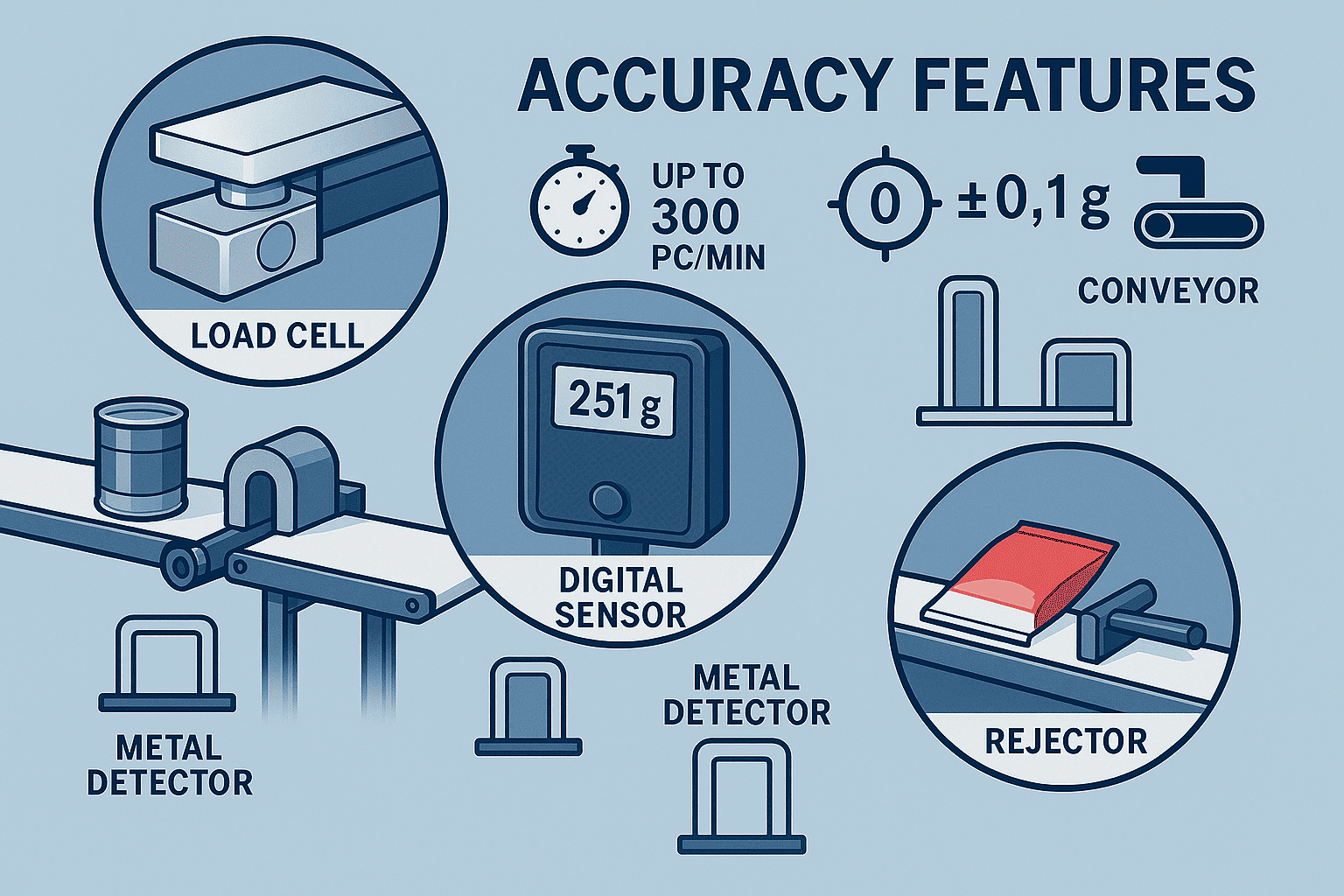

Checkweigher combination systems are vital for modern manufacturing, particularly in the food industry, where they verify that products meet weight specifications while detecting metallic contaminants. A checkweigher system measures product weight in real-time to ensure compliance with design norms and regulations, preventing underfilled or overfilled packages that could lead to waste, recalls, or legal issues. Integrated with a metal detector, it scans for unwanted metal impurities like fragments from machinery, safeguarding consumer health and brand reputation.

These systems often incorporate additional components:

● Conveyors: For smooth product flow at variable speeds.

● Rejectors: Automatic mechanisms (e.g., push rods or sliders) to remove non-compliant items.

● Printers/Labelers: For applying batch codes, weights, or compliance labels.

● Metal Detectors: Using electromagnetic induction to identify ferrous and non-ferrous metals.

At SameGram, our Checkweigher with Metal Detector Combination System SCM-4530L2 model exemplifies this integration, offering a compact design with independent rejectors for weight and metal issues, supporting a weighting range of 1-2000g at belt speeds of 5-28m/min, and featuring touchscreen controls for easy operation. This setup not only saves space but also enhances traceability through MES/ERP connectivity.

Key Consideration 1: Compatibility and Seamless Integration

One of the primary challenges in purchasing a checkweigher combination system is ensuring it fits your existing production line without causing bottlenecks. Evaluate compatibility with current equipment, such as conveyors and software systems, to enable real-time data exchange and automated feedback loops.

● Practical Advice: Assess throughput needs—our systems support adjustable belt speeds from 5-28m/min, but match this to your line speed to avoid disruptions. The SCM-4530L2 integrates metal detection and weighing via a single controller, reducing setup complexity.

● Integration Benefits: Modular designs allow easy addition of other inspection systems for broader inspections. Our systems emphasize checking data formats and connectivity (e.g., USB export) for backend integration.

● Solving User Problems: In food production, where lines handle wet or sticky items, choose IP-rated systems for washdown compatibility, minimizing downtime during cleaning.

SameGram's systems excel here, with a modular architecture that adapts to diverse layouts. Our High-Precision Checkweigher series integrates effortlessly with metal detectors, as seen in the SCM-4530L2, which offers customizable rejectors and real-time ERP links to streamline operations and reduce manual interventions.

Key Consideration 2: Accuracy, Speed, and Precision

Accuracy is non-negotiable for compliance with standards like HACCP, GMP, and MID. Look for systems with advanced load cells and dual-frequency metal detection to handle varying product types without false positives.

● Practical Advice: Consider weight ranges (e.g., 1-2000g for SameGram's SCM-4530L2) and accuracy (±0.3-1g). High-speed models suit fast lines, while our technology ensures milligram precision for pharmaceuticals.

● Environmental Impact: Factors like vibrations, temperature, or air currents can affect readings—opt for robust designs like our electromagnetic induction tech, which optimizes for ferrous/non-ferrous detection with sensitivities such as Fe: 0.6-1.2mm, Non-Fe: 0.8-1.5mm, and Sus: 1.2-2.0mm.

● Solving User Problems: In high-volume food lines, separate rejectors (as in our dual setup) help isolate issues, allowing quick root-cause analysis and reducing waste.

With SameGram's expertise, our systems achieve high precision, backed by over 5,000 installations worldwide. This precision helps clients like food processors maintain 99.8% accuracy, cutting labor costs by up to 40%.

Key Consideration 3: Space, Layout, and Hygienic Design

Space constraints are common in factories, so prioritize compact, modular systems that save up to 50% floor space compared to separate units.

● Practical Advice: Plan layouts for accessibility—our systems consider operator access and environmental factors like moisture. Hygienic designs use stainless steel and smooth surfaces for easy cleaning.

● Integration Challenges: Ensure the system fits end-of-line positions, with options for multilane setups in high-throughput scenarios.

● Solving User Problems: For food safety, high IP ratings prevent contamination during washdowns.

SameGram's Metal Detector Combination System SCM-4530L2 is designed for tight spaces, with a 304 stainless steel frame and flushable structure meeting GMP/ISO standards, making it ideal for hygienic food environments.

Key Consideration 4: Training, Support, and Long-Term Reliability

Invest in systems with robust after-sales support to minimize downtime and ensure ongoing compliance.

● Practical Advice: Look for warranties, remote diagnostics, and lifetime support.

● ROI Analysis: Calculate long-term savings from reduced waste and recalls—our systems enhance OEE through data analytics.

● Solving User Problems: User-friendly interfaces with multilingual touchscreens reduce training time, and real-time monitoring prevents issues before they escalate.

At SameGram, we provide a 12-month warranty, lifetime technical support, and free sample testing. Our global service ensures fast responses, drawing from our commitment to innovation to deliver reliable, customizable solutions.

Key Consideration 5: Cost, Compliance, and Industry-Specific Applications

Balance upfront costs with ROI, focusing on features that align with your industry—food demands high hygiene, while logistics prioritizes speed.

● Practical Advice: Compare models for compliance (e.g., CE, UL) and features like trend control for filling optimization. Our integrated metal detectors ensure food safety without extra costs.

● Solving User Problems: In pharmaceuticals, precise dosing prevents recalls; in food, contaminant detection protects brands.

Choose SameGram for cost-effective, certified systems. Visit our product page for the SCM-4530L2 to see how it addresses these needs: Checkweigher with Metal Detector Combination System.

Why Choose SameGram for Your Checkweigher Combination System?

With a mission to drive intelligent industry upgrades, SameGram has served over 5,000 clients, including leaders in food processing and pharmaceuticals. Our in-house R&D ensures modular, AI-ready systems that integrate weighing, detection, and labeling for smart factories. Experience our commitment to quality through free testing and tailored consultations—contact us today at SameGram Contact or explore our full range at SameGram Homepage.

This guide is based on extensive industry insights and SameGram's proven expertise, ensuring you select a system that resolves real-world challenges while elevating your production standards. For personalized advice, reach out to our team.

Related Hot-Sale Checkweigher

SC1-5040L5 is an economy and dynamic hi speed checkweigher ideal for in line weight checking with precision and reliability.

WSS-5012L2 is a compact weight sorter machine designed to ensure stable output and quality control. ideal for fish and meat.

SBW-2512B12 is a multi head combination weigher ideal for fast, precise dosing,also known as linear combination scale.

SCI is an automatic Checkweigher integrates industrial inkjet printer for real-time checkweighing and inkjet printing.

SCL-10060L50 is an automatic weigh price labeler with scanning, weighing scale label printing, and template customization.