How to Choose the Right Weigh Price Labeller for Your Production Line

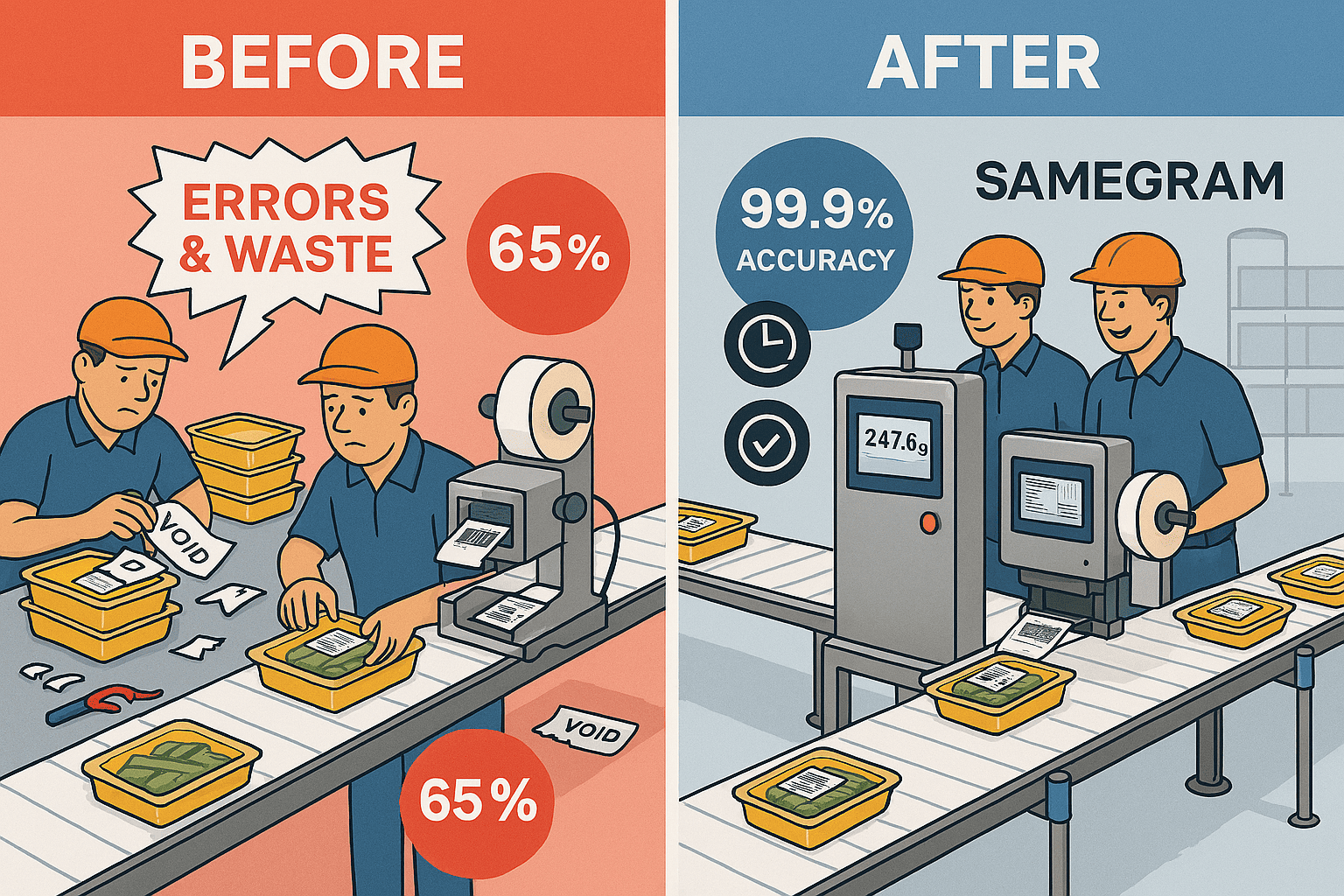

In the fast-paced world of manufacturing, especially in food and pharmaceutical production, getting labels right isn't just about aesthetics—it's about compliance, efficiency, and bottom-line savings. Imagine this: your team spends hours manually weighing products, scribbling weights on labels, and slapping them on packages, only to deal with errors that lead to rejected shipments or hefty fines. We've all heard the stories—wasted materials piling up, production lines grinding to a halt, and that nagging worry about whether your labels meet regulatory standards like FDA or HACCP. If you're searching for a "Food Labeling System" to streamline this chaos, you're not alone. Most operators in your shoes are looking for a system that automates the entire process: accurate weighing, instant printing, and precise application—all on one conveyor belt.

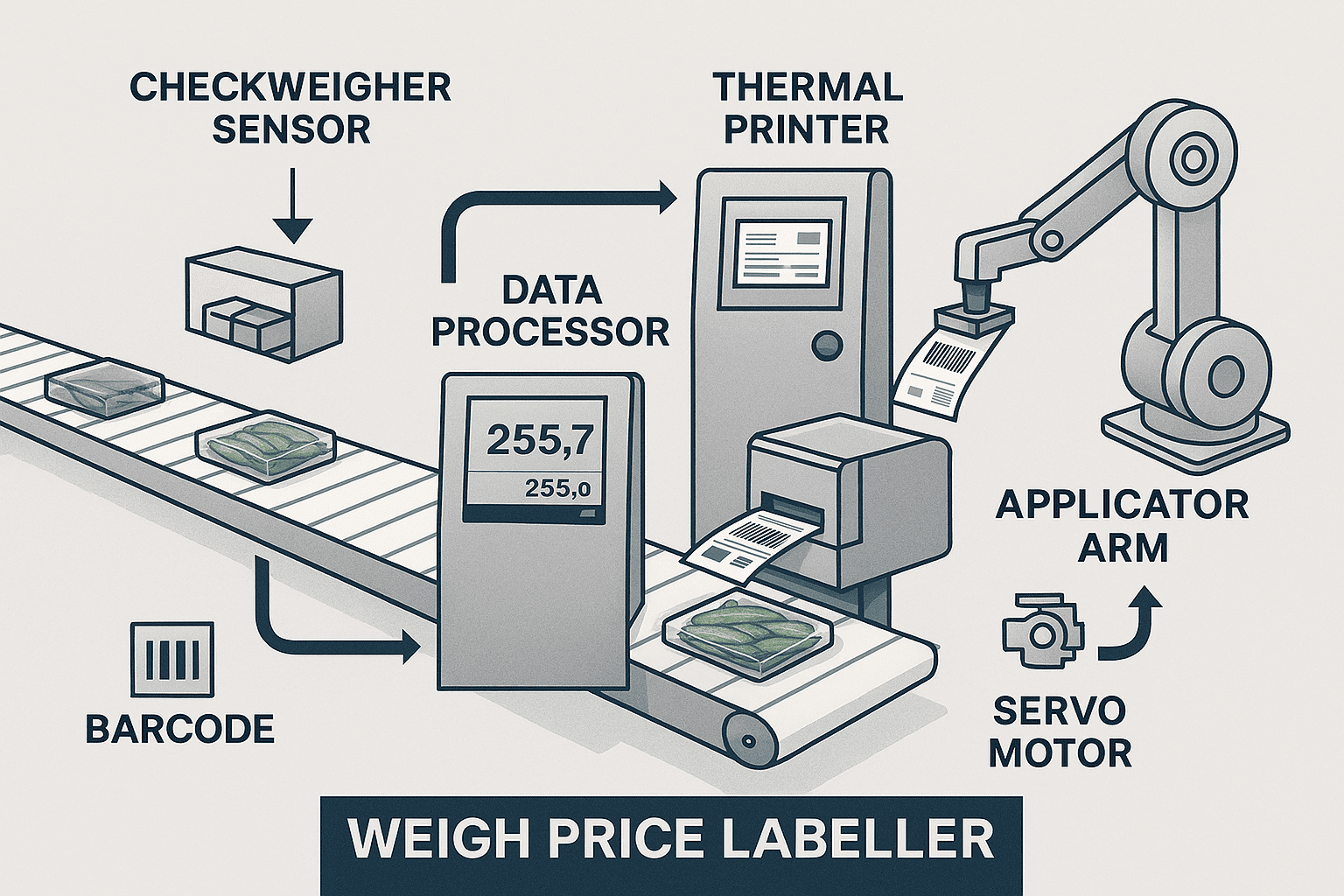

That's where a reliable Weigh Price Labeller shines. These integrated food labeling systems take the guesswork out of labeling by capturing real-time weight data from a checkweigher, feeding it directly to a printer for custom labels, and applying them flawlessly as products move along. At SameGram, with over 20 years of experience crafting these solutions, we've helped more than 5,000 facilities in 60+ countries turn these pain points into seamless operations. Our Weigh Price Labeler Machine isn't just a machine; they're tailored partners that boost accuracy to ±1mm and speeds up to 60 products per minute, ensuring your line runs smoother and your products hit the shelves compliant and competitive.

Why Your Line Needs a Weigh Price Labeller: Tackling Common Challenges

Let's start with the realities on the ground. Manual labeling isn't just slow—it's error-prone. A single misprinted weight can trigger recalls, erode trust, and spike costs. In high-volume settings like food packaging, where every gram counts for portion control and regulatory adherence, these slip-ups add up fast. Dynamic checkweighers solve the weighing part by verifying if products meet specs, rejecting outliers automatically to keep your output consistent. But pairing that with on-demand automatic food labeling systems? That's the game-changer.

An automatic labeler machine bridges the gap: as the checkweigher scans and weighs (down to ±0.3g accuracy in our systems), the data zips to the printer for labels that include weights, batch numbers, barcodes, and expiration dates. Then, the applicator—whether a gentle wipe-on for flat surfaces or a precise tamp for sides—affixes it without stopping the line. This all-in-one flow minimizes waste, cuts labor by up to 500%, and ensures traceability for audits.

From our vantage at SameGram, we've seen it firsthand. Our factory in a 4,000+ m² GMP-certified space produces these systems with rigorous multi-stage quality checks, using food-grade 304/316 stainless steel for IP65–IP69K protection. That means they're built for wet, dusty environments without compromising hygiene—perfect for ensuring your food products stay safe and spec-compliant.

Essential Features of a Top-Tier Weigh Price Labelling System

Not all food labeling systems are created equal, and skimping on features can lead to downtime or mismatched capabilities. When evaluating options, zero in on these core elements that make a weigh price labeling equipment truly effective for your line.

Real-Time Data Integration and Variable Printing

At the heart of any solid system is seamless data flow. Look for thermal transfer printing that handles variable data—like live weights from the checkweigher—without batching delays. This tech uses heat to fuse ink ribbons onto labels, delivering smudge-proof results that withstand harsh conditions. Our SameGram Weigh Price Labeler Machines support this with Ethernet/IP and Modbus connectivity, syncing instantly to your MES/ERP for full traceability. No more static labels; every package gets a unique, accurate tag, reducing errors and supporting GS1 barcode standards right out of the box.

Versatile Applicator Mechanisms

How labels get applied matters as much as what's printed on them. Pneumatic tamp-blow applicators excel for non-contact placement on uneven surfaces, like soft pouches, using controlled air bursts for speeds up to 50 ppm. Electric wipe-on options, on the other hand, offer precision for flat or wraparound needs with minimal air use, cutting energy costs. SameGram's modular designs let you mix and match—say, a servo-controlled arm for ±2mm accuracy on bottles or boxes—ensuring adaptability without overhauling your setup.

Durability and User-Friendly Design

In a real factory, machines take a beating. Prioritize stainless steel builds with enclosed, washdown-ready components to meet hygiene regs. Ease of use seals the deal: intuitive touchscreens with multi-language support, event logs, and auto-adjust for product sizes mean your operators spend less time troubleshooting and more on production. Our Weigh Price Labeling Equipment includes these, plus remote diagnostics for quick fixes, backed by our 12-month warranty and lifetime maintenance.

A Step-by-Step Guide to Selecting Your Weigh Price Labeller

Choosing the right Weigh Price Labeling Equipment doesn't have to feel overwhelming. Follow this practical roadmap, drawn from years of guiding manufacturers like yours, to match tech to your needs.

Step 1: Assess Your Throughput and Product Specs

Start with volume: How many units per minute does your line handle? For low-to-mid speeds (15-40 ppm), a compact model suffices; high-volume ops need 50+ ppm to avoid bottlenecks. Factor in product shape—round bottles might call for wraparound applicators, while flat trays suit top-tamp. Label sizes? Ensure the Weigh Price Labeling Equipment accommodates your rolls (e.g., 1-4 inches wide) without frequent swaps. At SameGram, our SCL-7035L5 Automatic Weigh Price Labeler hits 15-50 ppm for 1-5000g ranges, perfect for versatile food lines.

Step 2: Prioritize Compliance and Integration

Regulations like HACCP demand accurate weights and scannable codes—verify your labeller supports 1D/2D barcodes and real-time verification. Integration is key: Does it plug into your conveyor and software without custom coding? Our Automatic Weigh Price Label Systems do this effortlessly, merging checkweighing with labeling in a single footprint, saving space and simplifying installs.

Step 3: Evaluate Maintenance, Cost, and Scalability

Upfront price is tempting, but calculate total ownership—energy-efficient designs and easy-access parts slash long-term costs. Opt for modular builds that scale with growth, like adding vision checks later. SameGram's IQC-to-FAT quality process ensures reliability and fast deliveries.

Step 4: Test and Validate

Don't buy blind—request demos or sample runs. Our free test piece service lets you verify accuracy on your products, confirming the system fits like a glove.

This guide isn't theory; it's battle-tested advice from outfitting lines worldwide.

Real-World Wins: How SameGram Weigh Price Labeler Machines Transform Operations

Seeing is believing, especially when it comes to factory floors. Take a packaged vegetable producer we partnered with—they were drowning in manual weigh-label errors, failing export hygiene checks, and losing 10% of output to rejects. We deployed our SL-V Weigh Price Labeller integrated with a checkweigher: real-time weight capture at ±2g, thermal printing for batch/weight labels, and servo-applied tags at 40 ppm. Result? 99.9% accuracy, zero compliance issues, and a 30% efficiency bump, all in a space-saving modular unit.

Another case: a cosmetics filler grappling with variable batch sizes on jars. Our SCM-4530L2 Automatic Checkweigher & Metal Detector Combination System handled 1-2000g weights with ±0.3g precision, printing and applying wrap labels on the fly. Downtime dropped 40%, and they scaled to new SKUs without line retools. These aren't outliers—our 5,000+ installs prove it.

Ready to Label Smarter? Let's Get Your Line Optimized

You've got the blueprint—now it's time to act. A well-chosen Automatic Weigh Price Label Systems isn't an expense; it's an investment that pays off in compliance peace, faster throughput, and fewer headaches. At SameGram, we're not just vendors; we're your automation allies, with CE/ISO-certified expertise and customization that fits your exact line.

Visit SameGram to explore our full range, or contact us for free sample testing. Let's weigh in on your success—together.