How High-Speed Checkweighers Reduce Waste & Boost Productivity

Introduction

In today's fast-paced manufacturing landscape, ensuring product quality while minimizing operational costs is paramount. High-speed checkweighers are indispensable tools for factories, particularly in industries like food, pharmaceuticals, and logistics, where they verify that products meet precise weight specifications. By automating weight inspections, these devices help prevent inconsistencies that could lead to waste, recalls, or regulatory issues. At SameGram, a leading provider of intelligent weighing and automation solutions with over 5,000 success stories worldwide, we specialize in high-precision and ultra-fast checkweighers designed to optimize production lines. This article explores how our dynamic checkweigher system for precision weighing reduces waste and enhances productivity, drawing on our expertise to offer practical insights for manufacturers seeking efficiency gains.

A high-speed checkweigher is an automated system that measures the weight of products in motion on a production line, ensuring they comply with design and regulatory standards. Unlike manual weighing, which is prone to errors and slowdowns, these machines operate at rapid speeds to maintain throughput without sacrificing accuracy. They are crucial for detecting underweight or overweight items, which could otherwise result in product rejection, customer dissatisfaction, or legal penalties.

At SameGram, our high-precision and ultra-fast checkweighers exemplify this technology. Built with stainless steel for hygienic compliance, they feature modular designs that integrate seamlessly with existing lines. For instance, our systems support maximum inspection speeds of up to 300 pieces per minute, with weighing ranges from 0.1g to 80kg and accuracies as fine as ±0.05g, depending on the model. This precision ensures every product—from food packets to pharmaceutical bottles—meets exact specifications, addressing real-world challenges like varying product sizes and high-volume demands.

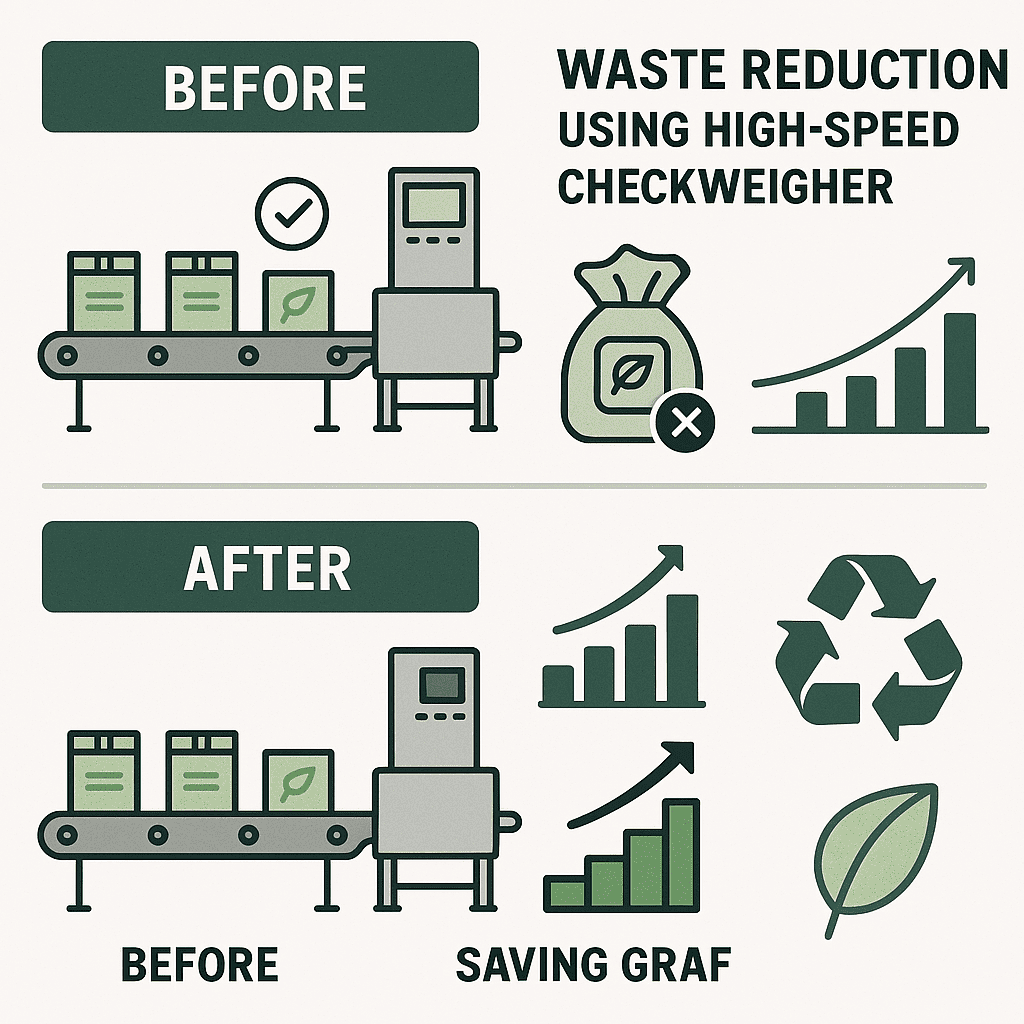

How Dynamic High-Speed Checkweighers Reduce Waste

Waste in manufacturing often stems from overfilling, underfilling, or defective products slipping through quality checks. Dynamic high-speed checkweighers tackle these issues head-on by providing real-time monitoring and automated corrections, leading to significant material savings and environmental benefits.

Preventing Overfilling and Underfilling

Overfilling occurs when excess material is added to products to compensate for potential inaccuracies, resulting in "giveaway" that erodes profits. Conversely, underfilling can lead to non-compliant products that must be discarded or reworked. Our in-motion checkweighers at SameGram use advanced sensors and high-resolution load cells to measure weights dynamically, comparing them against predefined targets. If a discrepancy is detected, the system automatically rejects the item via mechanisms like air blasts or pushers, preventing it from advancing.

For example, in food production, where nutritional labeling requires precise portion control, our devices minimize giveaway by adjusting upstream processes in real time. This not only reduces raw material waste but also avoids costly fines from regulatory bodies. Manufacturers using our systems report reduced waste by identifying patterns—such as inconsistent filling from machinery wear—and enabling proactive fixes.

Real-Time Data for Process Optimization

Integrated software in our dynamic checkweigher machine collects and analyzes weight data, generating reports that highlight trends in rejects. This allows operators to pinpoint inefficiencies, like variations in ingredient density or environmental factors affecting scales. By feeding this data back to fillers or mixers, production lines can self-correct, cutting waste at the source.

In practical terms, if a batch shows consistent underweight trends, the system alerts staff to recalibrate equipment, preventing entire runs from being scrapped. Our models support data logging with USB or Ethernet exports, facilitating audits and continuous improvement. This data-driven approach has helped our clients in the pharmaceutical sector avoid waste from non-compliant dosages, ensuring every tablet or capsule meets strict standards.

Sustainability and Cost Savings

By curbing waste, high-speed checkweighers contribute to sustainable operations. Less material usage means lower environmental impact, aligning with eco-conscious consumer demands. Financially, the savings are tangible: reduced giveaway translates to preserved profits, while fewer rejects minimize rework labor and disposal costs. SameGram's checkweighers, with their IP65-rated waterproof and dustproof designs, endure harsh environments, extending equipment life and further reducing long-term waste.

Boosting Productivity with Customization Dynamic Checkweigher

Productivity hinges on speed, accuracy, and minimal downtime. High-speed checkweighers accelerate workflows by automating inspections, allowing lines to run faster without quality compromises.

Enhancing Throughput and Efficiency

Manual weighing bottlenecks production, but our ultra-fast checkweighers handle belt speeds up to 120m/min, processing hundreds of items per minute. This seamless integration eliminates pauses, boosting overall line efficiency. For logistics applications, where parcels vary in size, our systems with multi-lane controls ensure uninterrupted flow, increasing daily output.

In manufacturing, automation reduces human error— a common productivity killer. Our touch-screen interfaces allow quick setup changes, minimizing transition times between product runs. Features like auto-zeroing between items maintain accuracy at high speeds, ensuring consistent performance even in vibrating environments.

Integration for Streamlined Operations

SameGram's integrated checkweighers are designed for easy integration with complementary systems, such as metal detectors, labelers, or barcode scanners. This creates a unified inspection station that performs multiple checks in one pass, slashing processing time. For instance, in cosmetics production, combining weight verification with labeling ensures compliant, ready-to-ship products without additional steps.

Remote diagnostics and online commissioning further enhance productivity by reducing onsite maintenance needs. Our 12-month warranty and lifetime technical support mean quick resolutions to issues, keeping lines operational.

Labor Optimization and Scalability

By automating routine tasks, precision checkweighers free up staff for higher-value roles, like oversight or innovation. Scalable designs accommodate growing operations, from small batches to high-volume lines. Clients in the food industry have seen productivity surges by using our systems to achieve 100% inspection rates, eliminating sampling errors and enabling faster market delivery.

Key Features of SameGram's High-Speed Checkweighers

Drawing from our in-house R&D and 4000+ m² manufacturing base with CNC machining and robotic welding, SameGram's checkweighers stand out for their reliability and innovation.

● Precision and Speed: Accuracies from ±0.05g and speeds up to 300 ppm for efficient, error-free weighing.

● Hygienic Construction: Stainless steel with GMP/ISO compliance, modular for easy cleaning and upgrades.

● Smart Connectivity: Real-time data analytics, Ethernet integration, and AI-assisted inspections for Industry 4.0 readiness.

● Customization: Tailored for specific needs, including explosion-proof options and wide weight ranges.

● Durability: IP65 ratings and vibration compensation ensure stable performance in demanding settings.

These features solve practical problems like hygiene in food processing or precision in pharmaceuticals, backed by our CE, ISO9001, and other certifications.

Real-World Applications and Benefits

In food production, our chain checkweighers ensure consistent weights for packaged goods, reducing waste from uneven fills and boosting output for high-demand lines. Pharmaceutical users benefit from dosage accuracy, preventing costly errors. Logistics firms appreciate the robust handling of varied parcels, enhancing sorting efficiency.

Benefits include up to 20-30% waste reduction (based on client feedback), faster ROI through cost savings, and improved compliance, all while supporting sustainable practices.

Why Choose SameGram?

As a high-tech enterprise with over 16 years of OEM/ODM experience, SameGram is your trusted partner in automation. Our 5,000+ success stories, rigorous quality controls (IQC, PQC, FQC), and global reach in 120+ countries underscore our expertise. We offer free sample testing, rapid prototyping, and comprehensive support, ensuring solutions that fit your needs.

Conclusion

High-speed checkweighers are game-changers for reducing waste and boosting productivity, offering precision, speed, and integration that address manufacturing challenges head-on. At SameGram, our advanced systems deliver these benefits with unmatched reliability.

Ready to optimize your line? Contact us for a free consultation or demo.