Checkweigher & Labeler Guide: Installation & Maintenance

In the fast-paced world of manufacturing, especially in industries like food processing and pharmaceuticals, ensuring product quality and compliance is non-negotiable. Dynamic checkweigher systems play a crucial role here, verifying that each item's weight meets exact specifications to avoid underfills or overfills that could lead to regulatory issues or customer dissatisfaction. When paired with a weigh price labeller, the system takes it a step further: after weighing, it seamlessly transmits data to print and apply customized labels with weight, price, and other details right on the production line. This integrated process—weighing, labeling, and applying—all on one conveyor belt, streamlines operations and boosts efficiency.

At SameGram, we've been at the forefront of this technology for over 16 years, specializing in high-precision dynamic checkweigher systems and weigh price labellers that help businesses maintain consistency and traceability. Our dynamic checkweigher systems, like the Checkweigher with Labeller Combination System, are designed for real-time synchronization, reducing errors and supporting smart factory integrations. Proper installation and maintenance aren't just about keeping things running; they're key to maximizing longevity, minimizing downtime, and ensuring your investment pays off. In this guide, we'll walk you through practical tips drawn from our extensive experience, helping you get the most out of your equipment, particularly regarding in-motion checkweighers installations and labelling machine maintenance.

Industrial Weighing And Labelling Systems Pre-Installation Planning: Setting the Stage for Success

Before diving into setup, thoughtful planning can prevent headaches down the line. Start with a thorough site assessment. Evaluate your production area's space—our compact, modular designs at SameGram, such as the SCL-7035L5 Automatic Weigh Price Labeler, fit into tight layouts with a footprint that saves up to 40% more space than traditional setups. Check for environmental factors like temperature, humidity, and dust levels; our systems are built with IP66-rated stainless steel for washdown environments, making them ideal for wet or dusty conditions in food and pharma lines.

Next, ensure compatibility with your existing line. Consider conveyor speed—our weigh price labellers handle up to 50 pieces per minute with ±1mm labeling accuracy, syncing perfectly with an automatic checkweigher that offers ±0.5g precision for weights from 1g to 5kg. Test your power supply and connectivity needs; our industrial weighing and labelling systems support Ethernet/IP and Modbus for easy ERP integration, allowing real-time data tracking. We recommend conducting a free sample test through SameGram—send us your products, and we'll provide a detailed report on performance, including videos, to confirm fit.

Don't overlook staff training in this phase. Familiarize your team with basic operations via our virtual sessions, covering everything from touchscreen interfaces to hygiene protocols. This upfront investment reduces errors and ensures smooth adoption, aligning with our commitment to customer success, as seen in over 5,000 in-motion checkweighers installations worldwide.

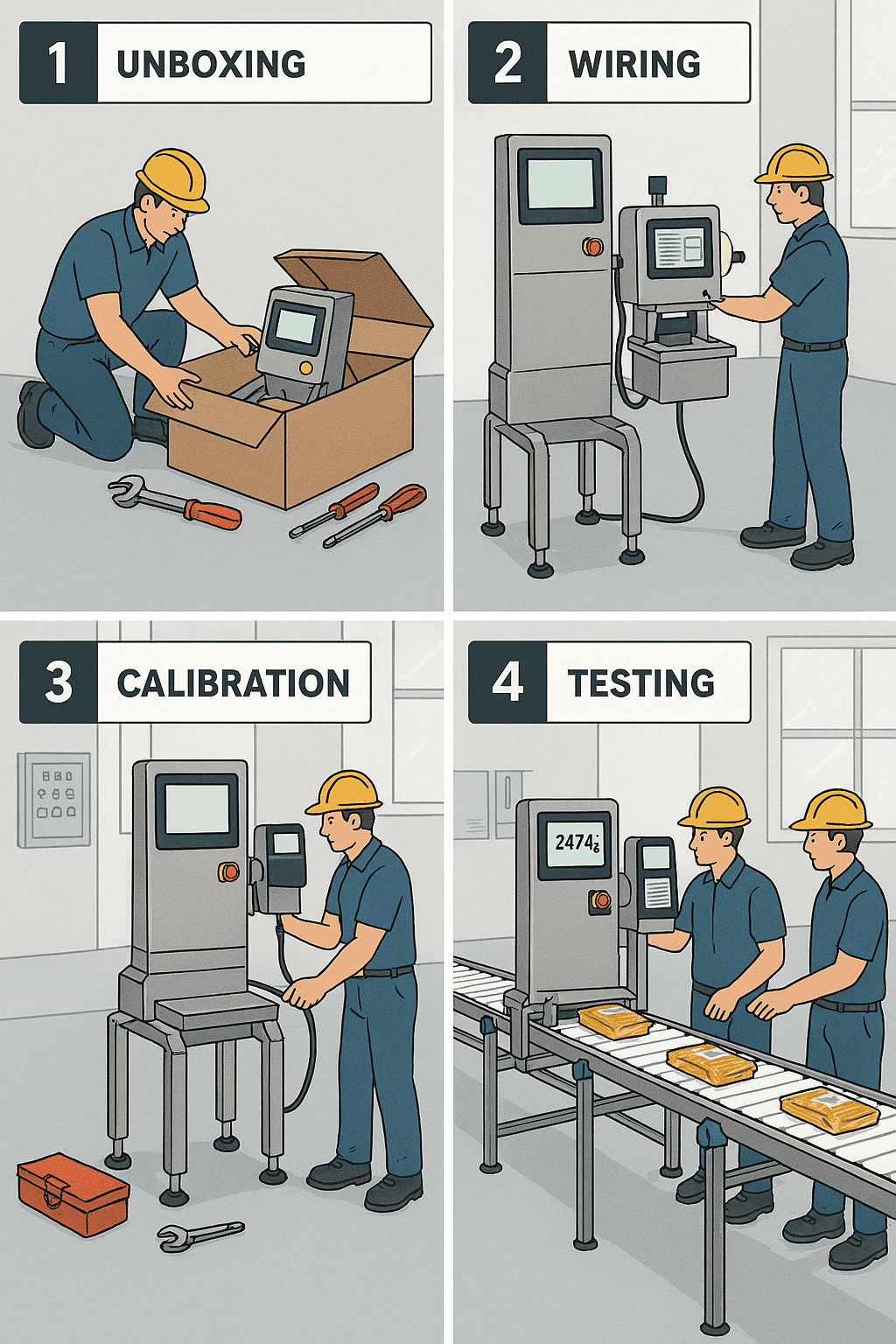

Step-by-Step Installation Guide: From Unboxing to Operation

Installing a checkweigher-labeling machine doesn't have to be daunting. Follow these steps for a hassle-free process, tailored to systems like our Checkweigher Machine with Labeller Combination System, which combines weighing accuracy of ±0.3g with high-speed labeling.

1. Unpack and Inspect: Carefully remove the machine from its packaging. Check for any shipping damage and verify all components—conveyor belts, sensors, labeling heads, and power cables—are present. Our units come pre-assembled where possible, with clear labeling for easy identification.

2. Positioning and Leveling: Place the machine on a stable, level surface in your production line. Use adjustable feet to ensure it's perfectly horizontal; even slight tilts can affect weighing accuracy. Integrate the industrial weighing and labelling systems into your conveyor system, aligning belts for seamless product flow at speeds up to 50m/min.

3. Wiring and Connections: Connect power according to the manual—our systems run on standard 220V supplies with built-in surge protection. Hook up data cables for integration; for instance, link the automatic checkweigher's output to the labeller's input for real-time weight-to-label transfer. Test Ethernet connections to your MES for data syncing.

4. Calibration: This is critical for precision. Power on and use the touchscreen to enter calibration mode. Place known test weights (we provide these with purchase) on the scale—calibration takes 10-60 seconds, depending on the model. Our algorithms auto-adjust for high-speed operations, ensuring compliance with standards like HACCP and FDA. For the labeller, calibrate print heads and sensors for ±2mm accuracy in label placement.

5. Testing: Run a trial batch. Monitor for smooth weighing, accurate data transmission, and flawless label application. Adjust rejection mechanisms if needed—our systems can eject non-compliant items automatically. If issues arise, our remote diagnostics team can assist via video link.

Throughout installation, safety is paramount: wear protective gear and follow lockout/tagout procedures. At SameGram, we offer on-site commissioning for complex setups, ensuring your system is up and running with minimal disruption.

Maintenance Best Practices: Keeping Your Industrial Weighing and Labelling Systems in Top Shape

Regular maintenance extends the life of your dynamic checkweighing systems and weigh price labeller, reducing costly breakdowns. Aim for a schedule based on usage—daily for high-volume lines, weekly otherwise.

Start with cleaning: Wipe down conveyor belts, weighing platforms, and labeling heads daily using mild, approved solutions to remove residues. Our hygienic designs make this easy, with flushable enclosures that meet GMP standards. Inspect sensors and load cells for dust; clean with compressed air to maintain accuracy.

Lubricate moving parts like rollers and chains every month, using food-grade lubricants to avoid contamination. Check belt tension and replace worn parts promptly—our modular setup allows quick swaps without tools.

Software updates are key; download the latest from our portal to fix bugs and enhance features, like improved AI for error detection. Perform calibration checks weekly with test weights to catch drifts early.

For the labeller specifically, monitor print heads and ribbon levels, cleaning them to prevent blurry labels. Our automatic checkweigher systems include auto-verification for barcodes, ensuring every label is scannable.

Document everything in a log—maintenance dates, issues spotted, parts replaced. This builds a history for predictive upkeep. At SameGram, our lifetime maintenance support includes remote monitoring, helping you stay ahead of problems.

Common Issues and Solutions: Tackling Problems Head-On

Even the best systems encounter hiccups. Here's how to address frequent ones in the auto checkweigher machine and weigh price labelling machine maintenance.

● Accuracy Drifts in Weighing: Caused by buildup or vibrations. Solution: Clean the platform and recalibrate using our guided touchscreen process. If persistent, check load cells—our high-precision models (±0.5g) rarely fail, but we offer quick replacements.

● Label Jams or Misalignments: Often from improper tension or dirty rollers. Clear jams by powering down and removing debris, then adjust tension settings. Clean sensors and realign heads; our servo-controlled applicators minimize this with ±1mm precision.

● Data Sync Errors: When weight info doesn't transfer to the labeller. Verify connections and restart software. Our real-time protocols ensure seamless integration, but if needed, our support can diagnose remotely.

● Inconsistent Adhesion: Due to surface dirt or wrong labels. Clean products pre-labeling and use compatible materials. Adjust pressure applicators for better stick.

● Sensor Faults: Interference from light or dust. Clean and shield sensors; our designs include protective housings.

Proactive checks during labelling machine maintenance prevent most issues. If you're using our combination system, its diagnostic tools flag problems early, saving time.

Warranty and Support: Peace of Mind from SameGram

Investing in quality means reliable backing. Our automatic checkweigher machine and weigh price labellers come with a 12-month warranty covering parts and labor, plus lifetime maintenance options. This includes free remote troubleshooting, software updates, and access to our expert team.

For complex needs, we provide onsite service through our global network, serving 120+ countries. Our OEM/ODM experience ensures tailored support, from custom integrations to compliance certifications like CE and ISO9001.

Contact us for extended plans or training—visit SameGram to get started.

Conclusion: Optimize Your Operations with Expert Help

Mastering installation and maintenance for checkweigher-labeling machines ensures reliable performance, compliance, and efficiency in your production line. By following these tips, you'll solve real-world challenges like accuracy maintenance and downtime reduction, ultimately boosting your bottom line.

At SameGram, we're more than a supplier—we're your partner in intelligent weighing solutions. Explore our full range of checkweigher system and labeling machines or request a free demo. For professional services, reach out today and let our 16+ years of expertise elevate your operations.

Hot-Sale Automatic Checkweigher Machine with Labeller Combination System

SCL-7035L5 is a weigh price labeler that integrates a weighing machine with label printer(s),which is very widely used

SCI is an automatic Checkweigher integrates industrial inkjet printer for real-time checkweighing and inkjet printing.

SCL-10060L50 is an automatic weigh price labeler with scanning, weighing scale label printing, and template customization.

SCL-8050L30 is an advanced automatic price weigh label machine with dynamic weighing, label editing, and MES/ERP integration.