Checkweigher & Modular Rejector Systems Guide | SameGram

In today's fast-paced manufacturing world, ensuring product quality and compliance is more critical than ever. Whether you're in the food, pharmaceutical, or logistics industry, maintaining precise weight control can make or break your operations. That's where advanced systems like the checkweigher come into play, seamlessly integrating with modular rejector systems to automate the process of weighing, labeling, and rejecting non-compliant items. At SameGram, we specialize in these technologies, helping businesses streamline their production lines while boosting accuracy and efficiency.

If you're searching for reliable solutions to handle weight discrepancies on your assembly line, you've come to the right place. This guide dives deep into how our dynamic checkweigher works hand-in-hand with modular rejector systems, focusing on sorting and rejection mechanisms that remove unqualified products without halting your workflow. We'll explore real-world applications, key features, and selection tips to help you solve common challenges like overfills, underfills, or contamination risks. By the end, you'll see why partnering with SameGram can elevate your production standards.

Before we get into the technical details, let's talk about who we are. SameGram is a high-tech enterprise with over 15 years of experience in developing dynamic checkweighers and automatic weighing inspection systems. Our R&D team, backed by multiple patents, focuses on creating intelligent, high-precision solutions that integrate seamlessly into your production environment. Operating from a state-of-the-art factory spanning more than 4,000 square meters, we handle everything from design to delivery, ensuring every product meets CE and ISO standards.

Our mission is simple: to make checkweighing easier and more reliable. We achieve this through modular designs that allow for easy customization, whether you're dealing with small pharmaceuticals or large logistics parcels. With over 5,000 successful installations of checkweigher systems worldwide, we've helped companies in food processing, cosmetics, and e-commerce reduce labor costs by up to 60% while improving product pass rates to over 99.8%. We offer one-stop services, including free sample testing, on-site installation, and lifetime technical support. Curious about our facilities? Explore Our Factory to see how we maintain top-tier quality control through rigorous processes like IQC, PQC, and Factory Acceptance Tests.

At SameGram, we're not just selling equipment—we're providing solutions that drive your business forward. Ready to upgrade your line? Contact Us for a personalized consultation.

Understanding the Role of Checkweigher System in Modern Production Lines

A checkweigher is an essential piece of automation equipment used in factories to weigh products dynamically as they move along the production line. Unlike static scales, our dynamic checkweigher systems perform real-time weight checks without stopping the conveyor, ensuring high throughput. For instance, models like the SC1-5040L5 High-Speed Belt Checkweigher can handle speeds up to 90 meters per minute, making them ideal for high-volume operations.

But it's not just about weighing—our checkweighers generate labels with accurate weight data and apply them directly to product packaging or boxes. This integration is crucial for compliance with regulations in industries like food and pharmaceuticals, where precise labeling prevents recalls and ensures consumer safety. Imagine a beverage line where bottles are filled, weighed, labeled with net weight and batch info, and then inspected—all in one fluid motion.

Key features of SameGram's checkweigher system include:

● High Precision: Accuracies as fine as ±0.02g for small items (e.g., SCP6 multi-lane model) up to ±10-30g for heavy parcels (SC3-10070L80 Checkweigher System).

● Modular Design: Easily customizable with options like barcode scanning, dimensioning, and integration with rejection systems.

● Hygienic Build: 304 stainless steel construction for washdown environments, compliant with HACCP and GMP standards.

● User-Friendly Interface: Color touchscreens with up to 100 presets, real-time data logging, and USB export for traceability.

These systems address real problems like inconsistent filling, which can lead to waste or customer complaints. In a case from a Zhejiang trading card manufacturer, our high-accuracy checkweigher with integrated rejector achieved ±0.1g precision at 120 packs per minute, slashing defect rates dramatically.

For those in logistics, our heavy-duty models like the SC3-L-12080S60 High-Speed Dynamic Weighing Scale handle oversized parcels up to 60kg, combining weighing with labeling for efficient shipping. If you're facing challenges with inline dynamic checkweigher setups or need a high-speed dynamic checkweigher for your line, our solutions are tailored to fit.

Integrating Modular Rejector Systems for Efficient Sorting and Rejection

Now, let's focus on the sorting and rejection system aspect. When a checkweigher detects a product that's underweight, overweight, or otherwise non-compliant, the modular rejector system kicks in to remove it from the line. This prevents defective items from reaching consumers, maintaining quality and reducing rework costs.

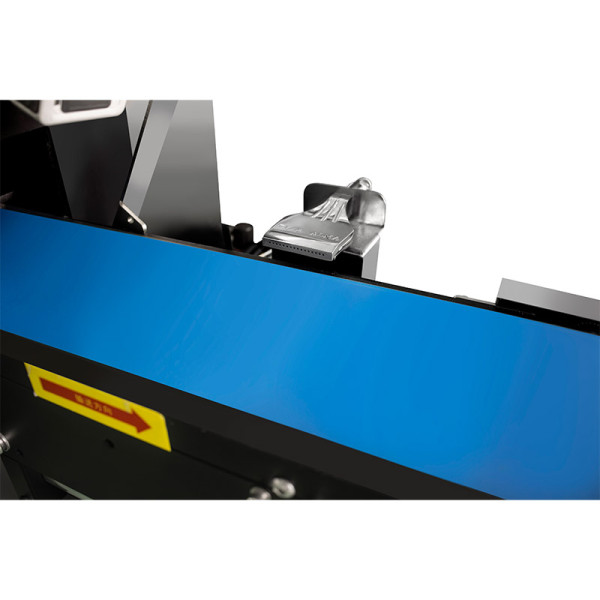

SameGram's modular rejector systems are designed for versatility, offering multiple methods to suit different product types. They're built with reinforced stainless steel frames, food-grade materials, and high waterproof ratings, making them perfect for automated lines. Driven by pneumatic or electric cylinders, these systems provide high precision and fast rejection speeds, directly replacing manual sorting to boost efficiency.

The beauty of our modular approach is flexibility—you can mix and match rejectors with checkweighers for a customized setup. For example, integrating with our dynamic checkweigher allows for automatic alarm signals that trigger rejection, ensuring seamless operation.

Types of Sorting and Rejection Systems and Their Implementations

Based on our extensive lineup, here are the main types of sorting and rejection system, their working principles, pros, cons, and best applications. We've drawn from proven designs to ensure they handle real-world scenarios effectively.

● How It Works: This non-contact method uses compressed air through solenoid valves to create high-speed pulses that blow lightweight defective products off the conveyor. It requires a stable air source (0.6-1MPa) and responds in under 0.1 seconds.

● Advantages: Fastest response for high-speed lines (300-600 items/min); no mechanical contact, ideal for fragile items; simple structure with low maintenance.

● Disadvantages: Limited to products under 1kg; depends on consistent air supply; can be noisy.

● Applications: Perfect for pharmaceuticals like boxed medicines or light food packaging in cosmetics lines.

● How It Works: A pneumatic or electric arm pushes non-compliant products sideways off the main line. Response time is 50-200ms, handling medium weights effectively.

● Advantages: Precise and cost-effective; strong load capacity (5-20kg); adaptable to various shapes.

● Disadvantages: Potential for impact damage on fragile items; moderate speed (150-300 items/min); needs side space.

● Applications: Great for daily chemicals like shampoo bottles or canned goods. Pair it with our SC3-8050L30 checkweigher for robust end-of-line checks.

● How It Works: A hinged section of the conveyor flips down (30-45 degrees) via cylinders or motors, dropping rejects into a collection bin.

● Advantages: Flexible for irregular shapes; good protection to the products with steady action; handles 1-10kg well.

● Disadvantages: Risk of product tumbling; more complex maintenance; slower flip action limits speed.

● Applications: Suited for fruits, vegetables, or frozen foods. In seafood processing, it gently sorts by weight without bruising.

● How It Works: The conveyor end tilts or drops, allowing rejects to fall or slide off. Variants include elevating or lowering mechanisms for controlled descent.

● Advantages: Fast and contact-free; strong for up to 50kg; no direct impact.

● Disadvantages: Space constraints vertically; potential drop damage; reset time affects frequency.

● Applications: Ideal for durable day-to-day products like detergents or boxed goods in high-speed lines.

● How It Works: Uses a rotating swing arm to divert non-compliant products from the main conveyor to a reject channel, supporting bidirectional sorting to either side.

● Advantages: Dual-direction rejection for left/right sorting, ideal for aquatic grading; handles medium to heavy products (≤15kg); high flexibility in directions.

● Disadvantages: Risk of jamming with soft packs or small items in arm-belt gaps; relatively complex mechanical structure.

● Applications: Aquatic product grading like abalone or sea cucumber; industrial parts, canned goods, and other medium-heavy items needing versatile diversion.

6. Telescopic Rejection (Belt Retractable)

● How It Works: A telescoping belt section retracts, creating a gap for rejects to fall through. Driven by cylinders or motors for smooth operation.

● Advantages: Provides excellent protection while minimizing damage.; simple and easy to clean; great for soft packs.

● Disadvantages: Slower speed (under 150 items/min); belt wear over time.

● Applications: Best for fragile foods or deformable bags, like snacks, where appearance matters.

7. Channel Diverter (Pivot Wheel Sorter)

● How It Works: Guides or diverts products to parallel reject lanes using wheels or boards, maintaining flow.

● Advantages: Highest precision with minimal disruption; The removal action is gentle and ensures the best continuity of production line; multi-level sorting; gentle on fragile items.

● Disadvantages: Requires more space; higher cost.

● Applications: High-speed bottling or electronics, where posture must remain intact.

These systems shine in sorting and rejection scenarios, classifying products by weight grades or removing contaminants. For instance, our weight sorters like the SWS-4523L2-C6 Waterproof Multistage Weight Sorting Machine can grade seafood into multiple categories, integrating conveyor rejection system for defects.

Real-World Applications and Case Studies

To make this practical, consider a food processing plant struggling with inconsistent package weights. Implementing our Hygienic Dynamic Checkweigher SCF-4523L3 with a pusher rejector solved this by weighing at ±0.3g accuracy, labeling compliant packs, and rejecting outliers at belt speed of 5-90m/min. The result? Reduced waste by 40% and full compliance with food safety standards.

In pharmaceuticals, a client used our Multi-Lane Checkweigher SCP6 with air jet rejection for tablet packs. The system weighed tiny items (0.1-100g) dynamically, applied labels, and ejected underfills without contact, achieving 99.9% uptime.

For logistics, our heavy-duty checkweigher with pivot wheel sorter handles e-commerce parcels, weighing, labeling for shipping, and diverting oversized items. This cuts manual intervention and speeds up fulfillment.

These examples show how our systems tackle pain points like downtime, accuracy, and integration. If you're in bakery, dairy, or cosmetics, check out our Industry-Specific Solutions for more tailored ideas.

Selection Guide: Choosing the Conveyor Rejection System for Your Needs

Selecting a checkweigher and modular rejector system boils down to your product specs and line demands:

● Product Weight and Fragility: Light and fragile? Go for air jet. Heavier and durable? Pusher or drop.

● Line Speed: High-volume needs fast options like air blow; slower lines can use telescopic for protection.

● Space and Budget: Modular designs minimize space; start with cost-effective pushers if budget-tight.

● Integration: Ensure compatibility with labeling and data systems for full automation.

We recommend starting with our standard dynamic checkweigher paired with air jet conveyor rejection system for most light applications. For custom needs, browse Our Full Product Range or Rejector Options.

Why Choose SameGram for Your Checkweigher and Rejection Needs?

Our systems aren't just tools—they're investments in efficiency. With features like real-time data connectivity for Industry 4.0 and sustainable designs that cut energy use, we help you stay ahead. Plus, our 12-month warranty and global support ensure peace of mind.

Don't let weight issues slow you down. Visit SameGram or Contact Us to explore more or request a demo. At SameGram, we're committed to your success—let's build a smarter production line together.

SCF-4523L3 is a hygienic food checkweigher with high precision and hi speed checkweighing for food industry,easy to integrate

SC-EP is a dynamic checkweigher for Ex zones, suitable for production lines with special requirements for explosion-proof

Up and Out Rejector for checkweigher and metal detector systems — stable, gentle, and precise for soft or thick products.

Air Jet Rejectors use powerful air bursts to remove lightweight or low-density items. Ideal for fast-moving lines.

The heavy-duty pusher rejector pair with checkweigher systems to deliver accurate, mid-speed removal of heavy, boxed items.