Benefits of Print and Apply Labeling Machines in Industrial Automation

In today's fast-paced manufacturing world, where every second counts on the production floor, inefficiencies can quickly eat into your bottom line. Imagine slashing labor time by up to 50% on labeling tasks alone— that's not a pipe dream, but a reality for factories adopting smart automation tools. At SameGram, with over 20 years of hands-on experience crafting precision weighing and labeling solutions, we've seen firsthand how integrating a Weigh Price Labeller transforms chaotic packaging lines into streamlined powerhouses. As a trusted partner in automation equipment manufacturing, serving industries from food processing to pharmaceuticals across more than 60 countries, we're here to break down the game-changing benefits of the print and apply automatic labeling machine. And at the heart of it? Our print and apply labeling machines, a seamless combo of checkweighing and instant labeling that keeps your operations accurate, compliant, and ahead of the curve.

Whether you're battling inconsistent weights, mounting compliance pressures, or just looking to scale without adding headcount, these systems address real-world headaches head-on. Let's dive into why the weigh price labelling system isn't just equipment—it's your factory's secret weapon for smarter automation.

Why Accuracy Matters: Precision Weighing Meets Instant Automatic Labeling

One of the biggest pain points in industrial packaging? Human error in weighing and labeling can lead to costly recalls or fines. Print and apply labeling machines flip the script by delivering pinpoint accuracy right where it counts—on the line.

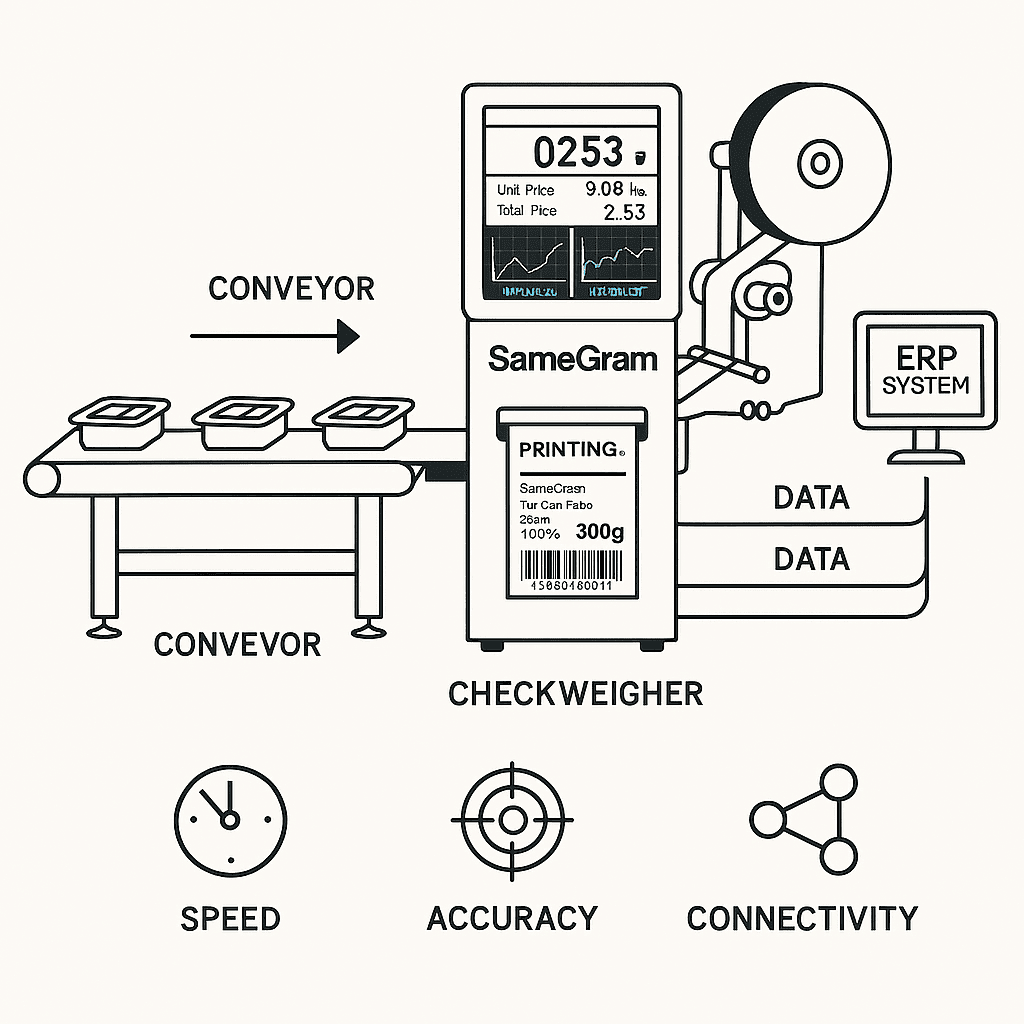

Take the automatic labeling system from SameGram: after a product passes through our high-precision checkweigher, the exact weight data zips straight to the integrated printer. Within milliseconds, a custom label prints with all the details—net weight, batch number, expiration date, and barcodes—then applies flawlessly to the package. No manual double-checking, no mismatched info. Our systems boast weighing accuracies as tight as ±0.3g for lighter items up to 2,000g, and ±0.5-2g for heavier loads up to 50kg, ensuring every label reflects reality.

This isn't theoretical. In a pharmaceutical setup we supported, the integration cut weight discrepancies by 99.9%, directly tackling the FDA and EMA's zero-tolerance for errors. For food producers, it means dodging those dreaded under/overfill violations that disrupt supply chains. And because it's all modular, you can tweak it for your specific needs—whether it's bottles, boxes, or bulk bags—without ripping up your line.

The result? Fewer rejects, happier regulators, and peace of mind knowing your products hit shelves exactly as intended.

Real-Time Customization: Diversified Labeling Solutions That Adjust Instantly

Static labels are so last decade. In dynamic environments like cosmetics or logistics, where SKUs change by the shift, you need automatic labeling that keeps up without halting production.

Enter the real-time magic of print and apply systems like our automatic labelling system. As products glide along the conveyor, the system pulls live data—weight from the checkweigher, plus inputs from your ERP or MES—and generates tailored labels on demand. Want to switch from 100g packs to 150g mid-run? No sweat. Our thermal printers handle variable data printing at speeds up to 40 products per minute, with servo-controlled applicators ensuring ±2mm placement accuracy every time.

We've engineered this for the grit of real factories: IP65-rated enclosures shrug off dust and splashes, while multilingual touchscreen interfaces make it intuitive for diverse teams. In one logistics case, a client in Vietnam integrated our system for fresh vegetable packs, boosting traceability for exports and cutting audit prep time in half. It's not just about slapping on a label—it's about embedding compliance and branding that evolves with your business, reducing the scramble for pre-printed rolls that often go to waste.

This adaptability shines in high-volume ops, where downtime for label swaps can cost thousands. With the weigh price labeling equipment, you're always one step ahead, customizing without compromise.

Cutting Waste and Boosting Sustainability: Less Scrap, More Savings

Waste isn't just an environmental headache—it's a profit killer. Over-labeled packages, discarded mismatches, or excess materials pile up fast in manual setups. Print and apply labeling machines like the Weigh Price Labeller tackle this by printing only what's needed, right then and there.

Our combination system minimizes scrap through synchronized processes: weigh, print, apply—all on one conveyor stretch. No excess labels cluttering bins; instead, you print variable quantities on-the-fly, slashing material use by up to 30% in typical runs. For eco-conscious manufacturers, this aligns perfectly with ESG goals—our FDA-compliant, food-grade stainless steel builds are recyclable and built to last, with over 5,000 units in the field proving their durability.

Consider a cosmetics line we optimized: by ditching batch-printed rolls for dynamic printing, they reduced adhesive waste and hit sustainability targets while maintaining throughput at 15-50 pieces per minute. It's practical problem-solving—fewer errors mean fewer rework cycles, and integrated reject arms divert off-spec items without bottlenecking the line.

In short, these machines don't just label; they optimize your entire resource loop, turning potential losses into lean gains.

Speed and Throughput: Keeping Your Line Moving Without Breaks

Speed is the lifeblood of industrial automation, but it's worthless if it sacrifices quality. That's where the Weigh Price Labeller excels, clocking belt speeds from 5-50 meters per minute while maintaining that razor-sharp accuracy.

The full cycle—weigh on the checkweigher, data transfer to the PC, print via thermal head, and apply via tamp-blow mechanism—unfolds in under a second per item. For lighter-duty apps, like electronics packaging, hit 60 products per minute; heavier pharma or food lines settle at 20-40, still a massive leap from hand-labeling's crawl.

Drawing from our 16 years of OEM expertise in a 4,000m² factory, we've fine-tuned these for seamless flow. Laser cutting and bending machine ensure components withstand 24/7 abuse, while multi-stage QC (from incoming parts to final FAT tests) guarantees uptime. One food client reported a 40% line speed bump post-install, directly from our Checkweigher Combination System SCM-4530L2, proving how this tech scales with your growth.

No more idle conveyors or rushed shifts—the diversified labeling solutions keep momentum high, so you meet deadlines without the drama.

SCM-4530L2 is a checkweigher metal detector combination system ,ideal for food processing and pharmaceutical on compact lines.

Categories: Checkweigher Combination System

Brand: SameGram

Model: SCM-4530L2

Weighting range: 1-2000g

Belt speed: 5-28m/min

Weighting accuracy: ±0.3-1g

Size of inspection: H 120mm*W 300mm

Size of weighing section: L≤200mm; W≤120mm;H≤100mm

Size of inspection section: L 450mm*W 230mm

Sensitivity of metal detection empty machine: Fe:0.6-1.2mm,Not Fe:0.8-1.5mm、Sus:1.2-2.0mm

Rejection mode: Push rod type, sliding type optional

Seamless Integration: Plugging into Your Existing Setup

Adopting new tech shouldn't mean a factory overhaul. Print and apply systems thrive on compatibility, and our automatic labeling machine is no exception.

It pairs effortlessly with conveyors, sorters, or fillers via standard protocols like Ethernet/IP, Modbus, or Profinet. Hook it to your ERP for auto-data pulls—batch info, weights, even inventory levels—and watch traceability skyrocket. For smart factories, our Industry 4.0-ready designs support AI-assisted inspections, turning raw data into actionable insights.

Integration tips from our on-site commissioning pros: Start with a free sample test to map your line's footprint—our modular setups save space, often halving the real estate of standalone units. Then, layer in vision checks for label verification. We've done this for over 120 countries' worth of clients, from dusty logistics hubs to sterile pharma cleanrooms, always with IQ/OQ/PQ protocols for validation.

The payoff? Minimal disruption, max ROI—your team trains in hours, not days, thanks to intuitive controls and our lifetime remote support.

Calculating Your ROI: A Simple Path to Proven Returns

Wondering if the weight price labelling systems pay for themselves? Let's crunch the numbers with a straightforward formula, grounded in real SameGram deployments.

Basic ROI Formula: ROI = (Savings from Labor + Material + Errors - System Cost) / System Cost × 100%

Example: Say your line labels 10,000 units weekly at $0.05 manual labor per label ($500/week). Switching to our system drops that to $0.025 ($250/week savings). Add 20% material waste reduction ($100/week) and halved error recalls ($200/week)—total savings $550/week, or $28,600 yearly. At a mid-range investment of $15,000 (including install), you're at 90% ROI in year one, scaling higher as throughput grows.

We've seen clients hit breakeven in 6-9 months, thanks to 12-month warranties and low-maintenance designs. Factor in our rapid prototyping—no long waits—and it's a no-brainer for scaling ops.

Real Stories from the Floor: How It's Working for Others

Don't just take our word—our 5,000+ success stories speak volumes. A pharma partner in Europe raved: "The automatic labeling system's ±0.3g accuracy met EMA specs flawlessly, boosting our line by 40%." In Vietnam's fresh produce scene, a packer noted: "Real-time labels cut our export audits in half—efficiency like never before."

These aren't outliers; they're the norm when you partner with SameGram's expert team, backed by ISO9001-certified manufacturing and CE compliance.

Ready to Weigh In on Smarter Labeling?

Print and apply labeling machines, especially a robust Weigh Price Labeler like SameGram's, aren't luxuries—they're essentials for staying competitive in industrial automation. From nailing accuracy to slashing waste, they solve the daily grind that holds factories back.

At SameGram, we're more than manufacturers; we're your allies in building efficient, compliant lines. With free consultations, on-site demos, and customization that fits like a glove, let's tailor a solution for you. Drop us a line today or subscribe for tips on automation upgrades—your next efficiency win starts here.

Hot-Sale Weigh Price Labeling Equipment

SL-V is a smart labeller with custom label printing, vision labeling, and real-time weight binding for post-pack inspection.

SL3 is a three-axis automatic label applicator machine designed for space-limited factories.

SL is an automatic labeling machine supports fast, precise labeling. Ideal automatic labeling machine for box dynamic labeling

SCL-8050L30 is an advanced automatic price weigh label machine with dynamic weighing, label editing, and MES/ERP integration.

SCI is an automatic Checkweigher integrates industrial inkjet printer for real-time checkweighing and inkjet printing.